A new type of crystalline silicon solar cell test classification method

A technology for solar cells and crystalline silicon, which is used in semiconductor/solid-state device testing/measurement, circuits, electrical components, etc. It can solve the problems of poor battery current and low matching, and achieve higher output, higher matching, and lower packaging. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 provides a method for testing and grading of crystalline silicon solar cells. The specific steps are as follows:

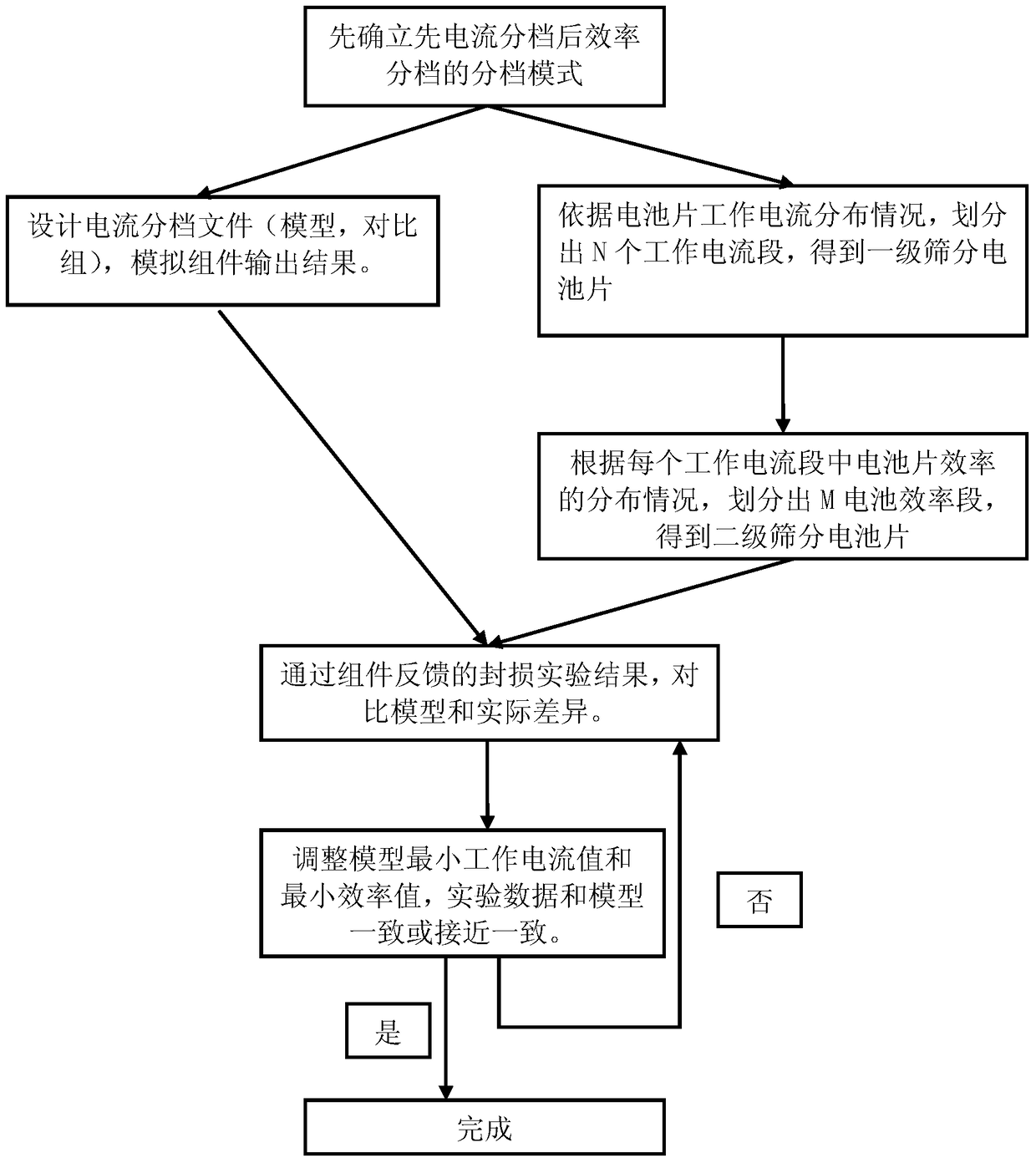

[0030] A: Establish the binning mode of current binning first and then efficiency binning, and use the computer to simulate the idealized model of the battery bin binning interval, conduct experiments on a large number of battery cells and collect data, and analyze the corresponding current interval in turn The pros and cons of each function of the cells in each efficiency range are screened. When the minimum operating current value of each segment and the minimum efficiency value of each gear are consistent or close to the idealized model, the control group distribution model is established.

[0031] B: Put each cell into the Halm tester equipment for test sorting;

[0032] S: In the test sorting step, the first stage of working current is prioritized:

[0033] S1: In step S, first perform a working current test on each cell to obtain the working curr...

Embodiment 2

[0043] In Example 2, the sorting test steps in specific work are as follows:

[0044] A batch of 156 polycrystalline cells with rounded corners was tested for working current, and the working current value was set to the optimal current range of [8.225A, 8.345A] after comparison.

[0045] After comparison, it is found that the optimal current interval needs to select two natural numbers as the interval range difference. Set the interval range difference to a1=0.05A and a2=0.07A respectively, then the optimal current interval is divided into two stages, respectively Are the first sub-current interval [8.225A, 8.295A) and the second sub-current interval [8.295A, 8.345A];

[0046] If the cells whose working current value belongs to [8.225A, 8.295A] are classified into the first sub-current interval, the first sub-current interval is defined as the first gear, and the working current value belongs to [8.295A, 8.345A] If the cells are classified into the second sub-current interval, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com