Control method enabling minimum operating time of batch process in controller asynchronous switching

A technology of running time and control method, applied in the information field, can solve problems such as long running time of intermittent processes and difficulties in efficient operation, and achieve the effect of reducing system state escape, reducing process running time, and promoting efficient production and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

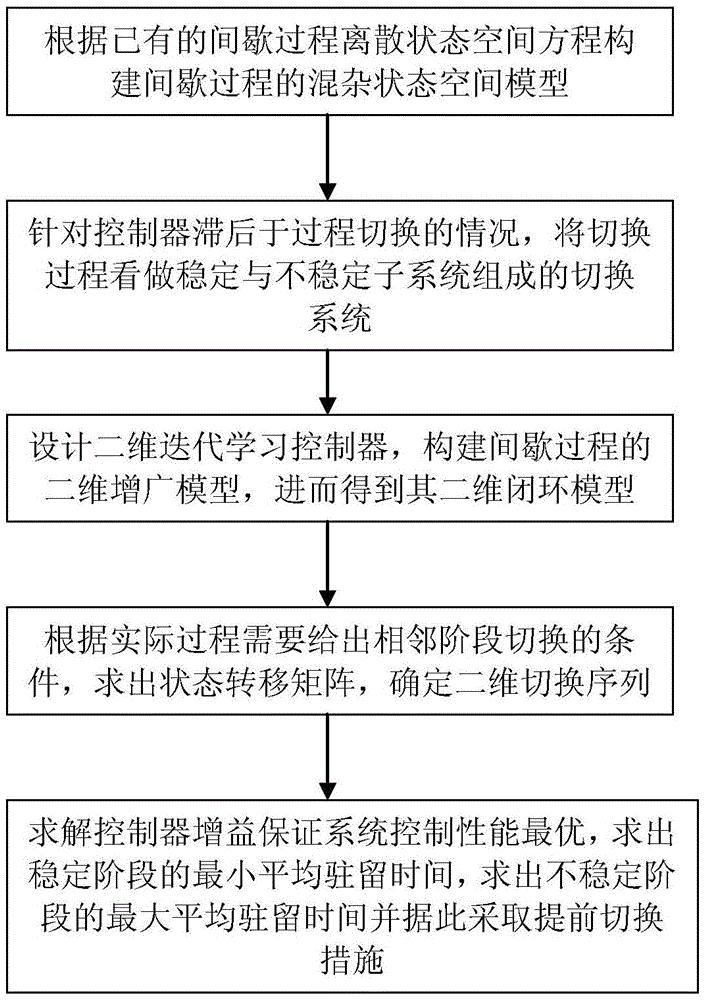

Method used

Image

Examples

Embodiment

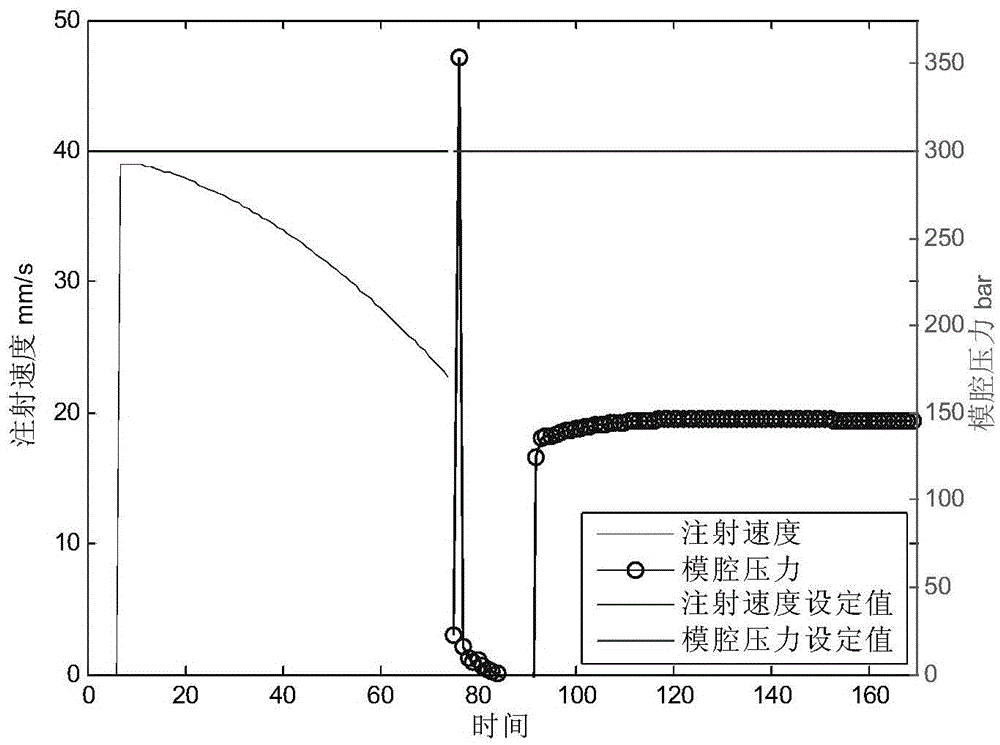

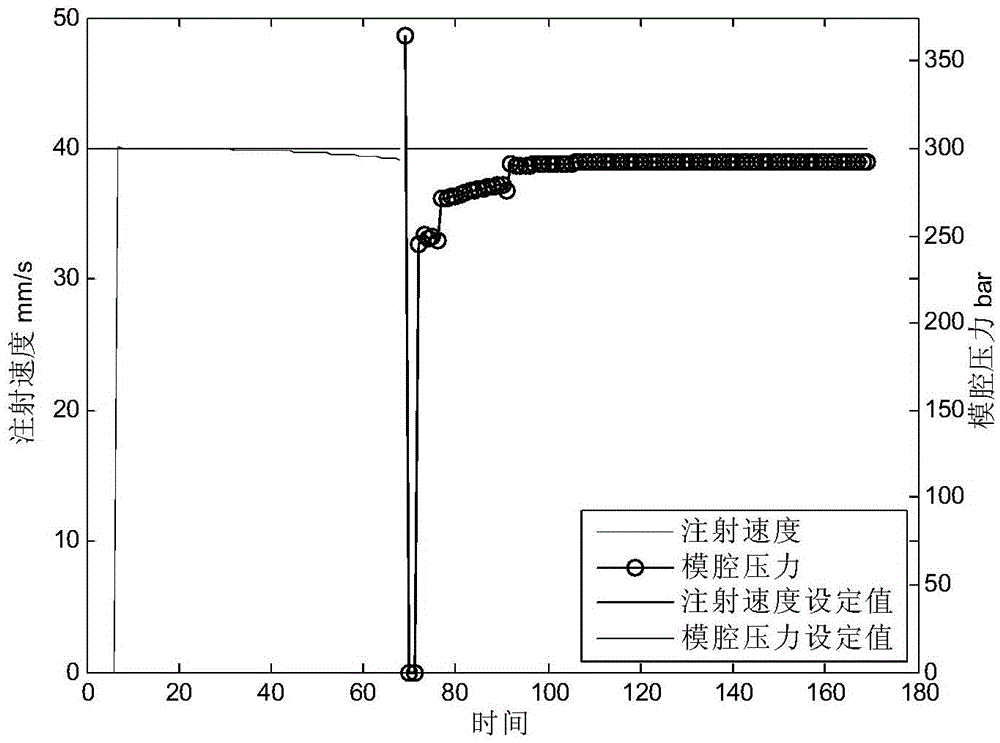

[0092] The injection molding process is a typical batch production process, and each batch mainly includes three steps, namely injection section→pressure holding section→cooling section. In the injection section, the screw moves forward to extrude the melt stored at the front end of the barrel (the raw material is heated by the heating ring) forward, flows through the runner, the runner, the gate, and enters the closed mold cavity ( inside the mold cavity). When the cavity is completely filled, the molding process switches from the injection section to the pressure holding section. In the pressure-holding section, the screw advances at a very low speed to maintain a certain nozzle pressure. A small amount of melt continues into the mold cavity, compensating for volume shrinkage due to cooling and solidification of the material. Once the gate with the smallest cross-sectional area in the mold is substantially solidified, the packing section stops and the process enters the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com