Doped polyaniline based solid acid radical electrode and preparation method thereof

A polyaniline and solid acid technology, which is applied in the field of electrochemical detection, can solve the problems that liquid membrane electrodes are not suitable for in-situ measurement, affect electrode stability, and are difficult to integrate electrodes, and achieve short measurement time, short response time, and easy volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

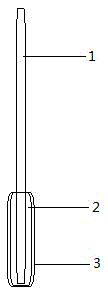

[0024] The steps of the preparation method based on the solid acid radical electrode of doping polyaniline are as follows:

[0025] 1) Clean the metal wire 1 with a length of 3-5 cm ultrasonically in acetone solution to remove surface oil, then ultrasonically clean it in 1-2M dilute hydrochloric acid to remove oxides, then ultrasonically clean it with deionized water and dry it ;

[0026] 2) Prepare 0.5-1M aniline hydrochloride solution with aniline and hydrochloric acid at a molar ratio of 1:1, or dissolve aniline hydrochloride flake solid in deionized water to prepare 0.5-1M aniline hydrochloride solution; The chemical workstation uses cyclic voltammetry to electroplate a layer of polyaniline 2 on the surface of the metal wire 1; wherein, the scanning voltage is 0-0.5V, the scanning speed is 50mV / s, and the scanning cycle number is 5-20cls; the metal in the three-electrode system Wire 1 is the working electrode, the auxiliary electrode is a Pt electrode, and the reference e...

Embodiment 1

[0030] 1) The gold wire 1 with a length of 3 cm was ultrasonically cleaned in acetone solution to remove surface oil, and then ultrasonically cleaned in 1M dilute hydrochloric acid to remove oxides, then ultrasonically cleaned with deionized water and dried;

[0031] 2) Add 4.66g of aniline and 50mL of 1M hydrochloric acid into a 100mL volumetric flask, add water to the mark line to prepare a 0.5M aniline hydrochloride solution; use cyclic voltammetry to electroplate a layer of polyaniline on the surface of gold wire 1 through CHI760D electrochemical workstation 2; Among them, the scanning voltage is 0-0.5V, the scanning speed is 50mV / s, and the scanning cycle number is 20cls; the gold wire 1 in the three-electrode system is the working electrode, the auxiliary electrode is a Pt electrode, and the reference electrode is a commercial Ag / AgCl Electrode; after the electroplating is completed, rinse the electrode with absolute alcohol to remove the aniline oligomers on the surface ...

Embodiment 2

[0034] 1) The silver wire 1 with a length of 4 cm was ultrasonically cleaned in acetone solution to remove surface oil stains, then ultrasonically cleaned in 2M dilute hydrochloric acid to remove oxides, then ultrasonically cleaned with deionized water and dried;

[0035] 2) Weigh 0.972g of aniline hydrochloride flaky solid and dissolve it in 15mL of deionized water to prepare a 0.5M aniline hydrochloride solution; use CHI760D electrochemical workstation to electroplate a layer of polyaniline 2 on the surface of silver wire 1 by cyclic voltammetry; Among them, the scanning voltage is 0-0.5V, the scanning speed is 50mV / s, and the scanning cycle number is 10cls; in the three-electrode system, the silver wire 1 is the working electrode, the auxiliary electrode is a Pt electrode, and the reference electrode is a commercial Ag / AgCl electrode; After completion, rinse the electrode with absolute alcohol to remove the aniline oligomers on the surface of the electrode, and wait for the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com