Gas-sensitive material for detecting NO2 and method for manufacturing gas-sensitive element made of gas-sensitive material

A gas-sensing material and nanofiber technology, applied in the field of gas detection, can solve the problems of low selectivity, affecting the measurement results and application range of the sensor, and small linear response range of the gas to be measured, and achieves good chemical dispersibility and simple preparation method. Controllable and improved gas-sensing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

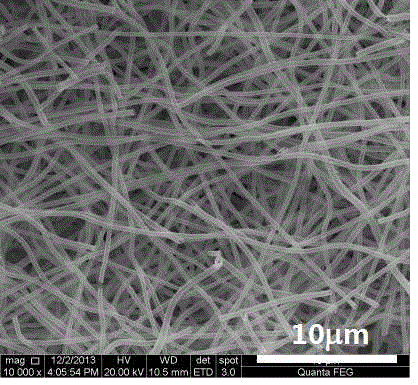

[0026] Preparation of SnO 2 Nanofibers

[0027] 0.6g stannous chloride (SnCl 2 2H 2 O) and 1g of polyvinylpyrrolidone (PVP) are added to 10ml of N,N-dimethylformamide (DMF) and absolute ethanol mixed solution (volume ratio DMF:ethanol=1:1), put it Mix evenly on a constant temperature magnetic stirrer, place the solution at room temperature and continue to stir for 24 hours until the solution is clear and transparent, and a uniform and viscous SnCl 2 / PVP precursor solution.

[0028] Pour the resulting precursor solution into a 10ml syringe, cover the syringe needle with a capillary nozzle, insert a metal needle into the syringe and connect it to the positive pole of the high-voltage power supply, adjust the syringe to a horizontal angle of 10°, and spread it on the metal receiving plate A piece of tin foil is used as the negative electrode, the distance between the receiving metal plate and the tip of the capillary is 15cm, and a voltage of 10kV is applied by the high-volt...

Embodiment 2

[0034] Noble metal Au modified SnO 2 Nanofiber material preparation

[0035] Get 0.01g stannous chloride and join in 20mL hydrochloric acid, then add 0.01g prepared SnO 2 Hollow nanofibers, after stirring at room temperature for 6h, the fibers were taken out and rinsed with deionized water for 5 times, and the SnO 2 Activation of hollow nanofibers. The activated fibers were added to 20 mL of 0.05 mmol / L chloroauric acid solution and stirred at room temperature for 2 h. The color of the fibers precipitated in solution changed from white to pink. The fibers were taken out and washed repeatedly with deionized water and ethanol, and then dried at 60°C for 24 h. The final Au-modified SnO 2 hollow nanofibers.

[0036] The product that this step makes is through X-ray diffraction analysis, such as figure 2 As shown, determine the rutile SnO 2 , (JCPDSNo.41-1445), the characteristic diffraction peaks of Au can be seen in the spectrum, and the existence of Au can also be seen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com