Measuring method of high-temperature oil-water relative permeability of heavy oil reservoir

A technology for relative permeability and heavy oil reservoirs, which is applied to the measurement field of high temperature oil-water relative permeability in heavy oil reservoirs, and can solve the problems of no simpler measurement method, cumbersome and complicated measurement process, and dangerous experimental conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

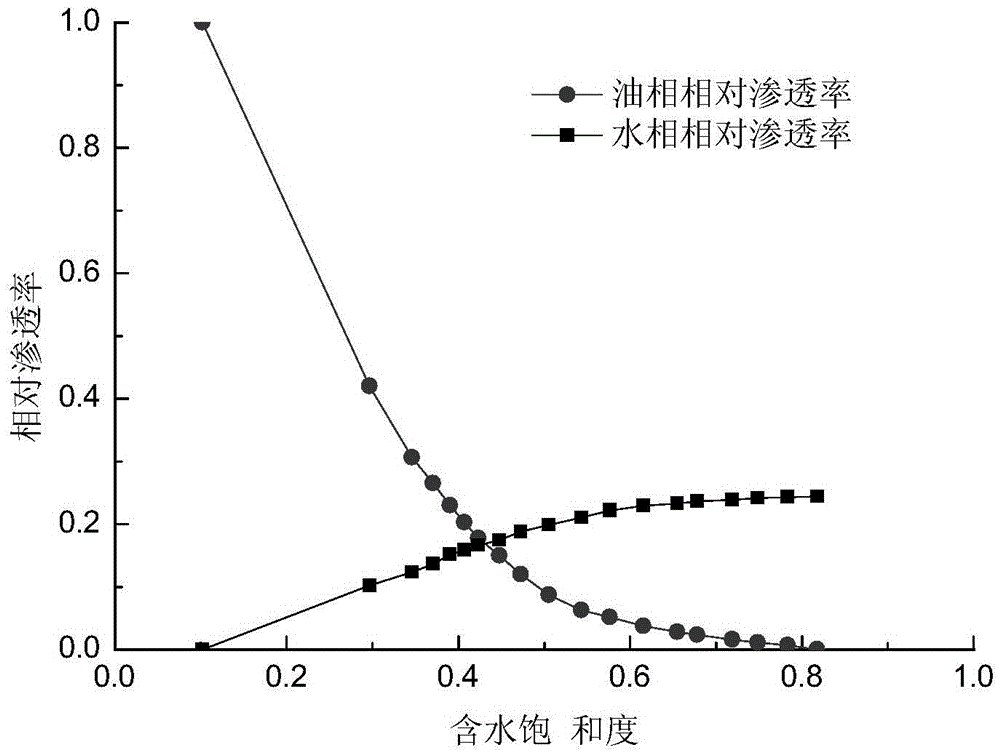

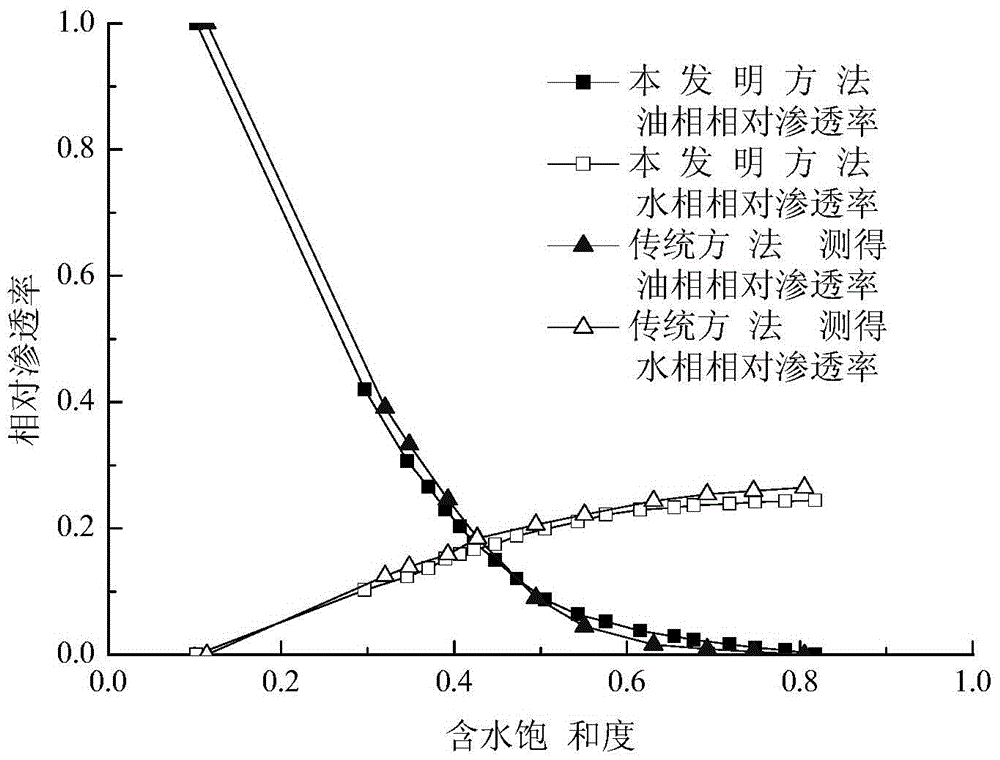

[0049] A method for measuring high-temperature oil-water relative permeability in heavy oil reservoirs, comprising the following specific steps:

[0050] 1) Prepare oil for experiment;

[0051] 2) Prepare the core: install the core in the sand filling pipe model, the size parameters of the core include: length L=60cm, cross-sectional diameter d=2.54cm, cross-sectional area A=5.07cm 2 , volume V f =304.02cm 3 The size of the core is the size of the sand-packing pipe model. The core here is filled with quartz sand that is similar to the particle distribution of the actual formation rock sample and has the same wettability according to the parameters such as the porosity and permeability of the actual formation. ;

[0052] 3) Check the tightness of the sand-packing pipe model, if the sealing of the sand-filling pipe model is good, record the absolute permeability K=2880mD of the rock core by gas testing method; saturate the sand-packing pipe model after vacuuming Water, recor...

Embodiment 2

[0085] A kind of measuring method of high-temperature oil-water relative permeability of heavy oil reservoir as described in embodiment 1, its difference is, described step 1) in the preparation method of experimental oil, comprises steps as follows:

[0086] 1.1) Measure the heavy oil to be tested at the temperature T 1 = Viscosity μ at 250°C o1 =4.64mPa·s;

[0087] 1.2) According to the relationship table between the viscosity and temperature of water in the "Chemical and Chemical Physical Properties Data Manual", it is found that the water is at the temperature T to be measured. 1 = Viscosity μ at 250°C w1 =0.11mPa·s and experimental temperature T 2 = Viscosity μ at 20°C w2 =1mPa·s, so as to calculate the temperature T to be measured 1 = Oil-water viscosity ratio at 250°C

[0088] 1.3) Use the heavy oil to be tested and naphtha to prepare the experimental oil, and measure the temperature of the experimental oil at the experimental temperature T 2 = Viscosity μ at 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com