In-situ torque testing device for micro-nano scale materials and observing device

A torque testing, micro-nano-scale technology, applied in measuring devices, using stable torque to test the strength of materials, analyzing materials, etc. Strict assembly requirements, limitations on the rapid development of micro-nano torsional mechanical testing technology, etc., to achieve good structural compatibility, simple structure, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

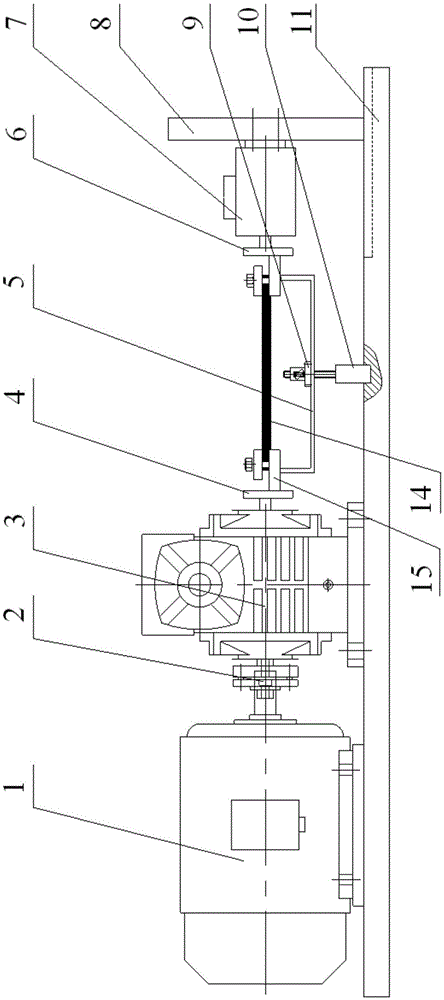

[0023] An in-situ torque testing device for micro-nano-scale materials, comprising:

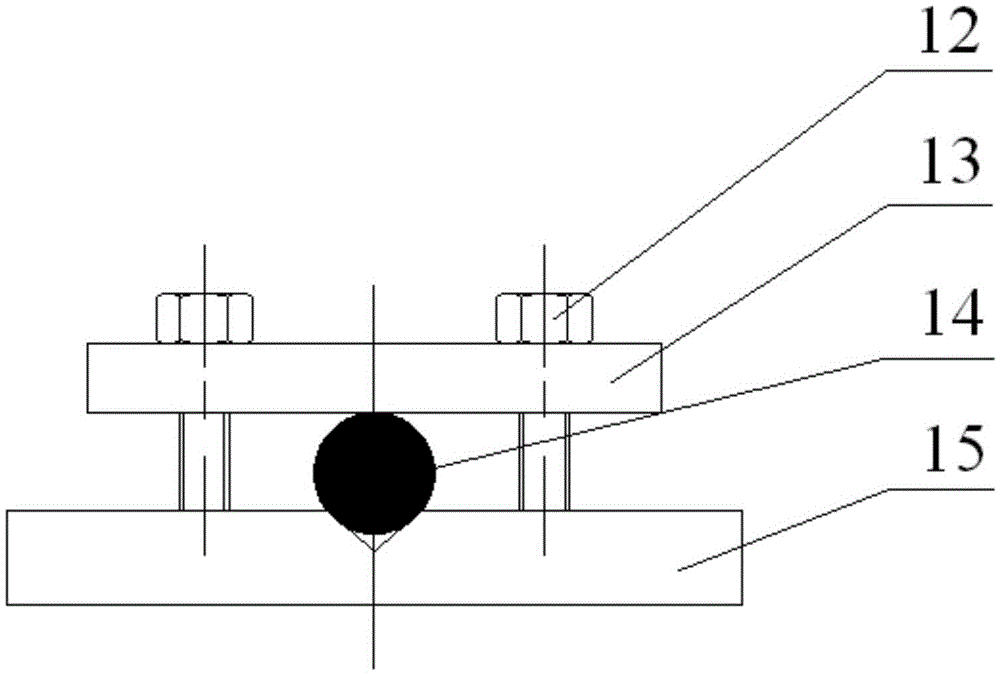

[0024] The clamping unit is used for clamping and fixing the test sample 14 in the form of filaments or wires, and the clamping unit includes two chucks;

[0025] The loading unit is used to drive the test sample 14 to twist, the loading unit includes a micro motor 1 capable of outputting torque, and the loading unit is connected to one end of the clamping unit;

[0026] The signal detection unit is used to detect the magnitude of the torque that the test sample 14 is subjected to, and the signal detection unit is connected with the other end of the clamping unit, such as figure 1 shown.

[0027] Since the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com