Experimental device and method for measuring the relationship between nozzle internal flow and cavitation erosion under multiple working conditions

A technology of internal flow and test equipment, applied in the direction of measuring equipment, fuel injection equipment, engine testing, etc., can solve problems that have not yet been developed, and achieve the effects of accelerating nozzle cavitation, improving fuel physical properties, and rapid cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The invention will be further described in detail below in conjunction with the drawings.

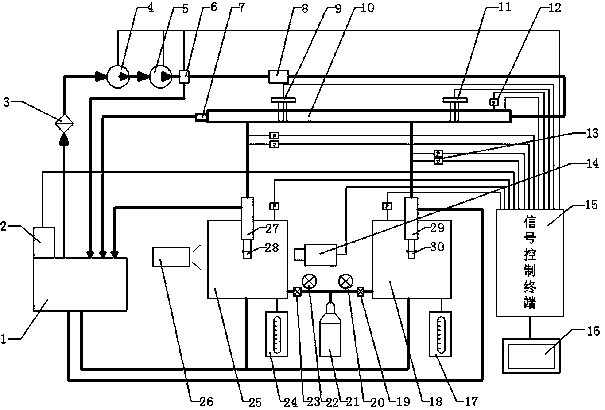

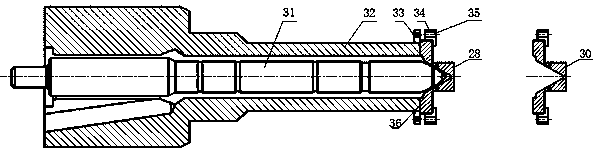

[0042] The invention relates to a test device that can measure the internal flow and cavitation relationship of a porous nozzle of a diesel engine under multiple operating conditions. figure 1 As shown in the figure, P represents the pressure transmission unit, V represents the flow transmission unit, and the thick solid line represents the oil circuit. The test device includes a pressure control system, a signal test system, an injection system and a fuel supply system.

[0043] The pressure control system includes a first electromagnetic oil pressure control valve, a second electromagnetic oil pressure control valve, a pressure regulating valve, a pressure limiting valve, a first back pressure chamber with a pressure control device, and a second back pressure chamber with a pressure control device body. The system controls the injection pressure of the oil circuit behind it by cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com