Constant-pressure non-negative pressure water supplying unit adopting permanent magnet synchronous motors

A permanent magnet synchronous motor, no negative pressure technology, applied in the direction of water supply device, water supply main pipeline, water supply pipeline system, etc., can solve the problem of not being a permanent magnet synchronous motor, and achieve the improvement of motor efficiency, stable operation, and improved unit efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

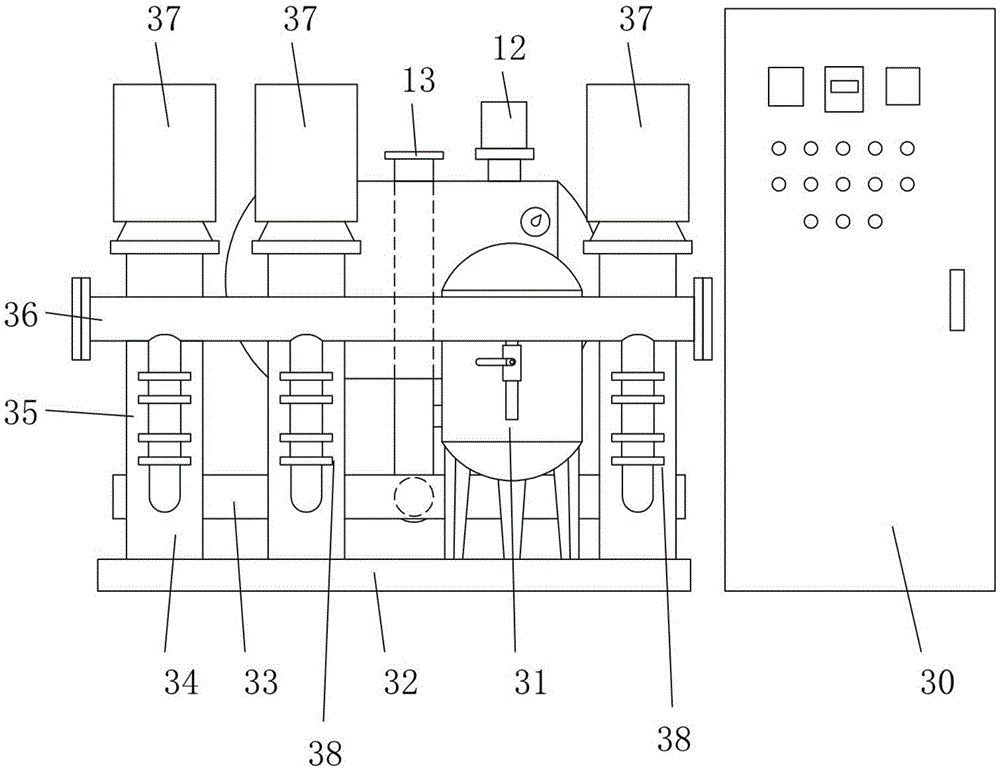

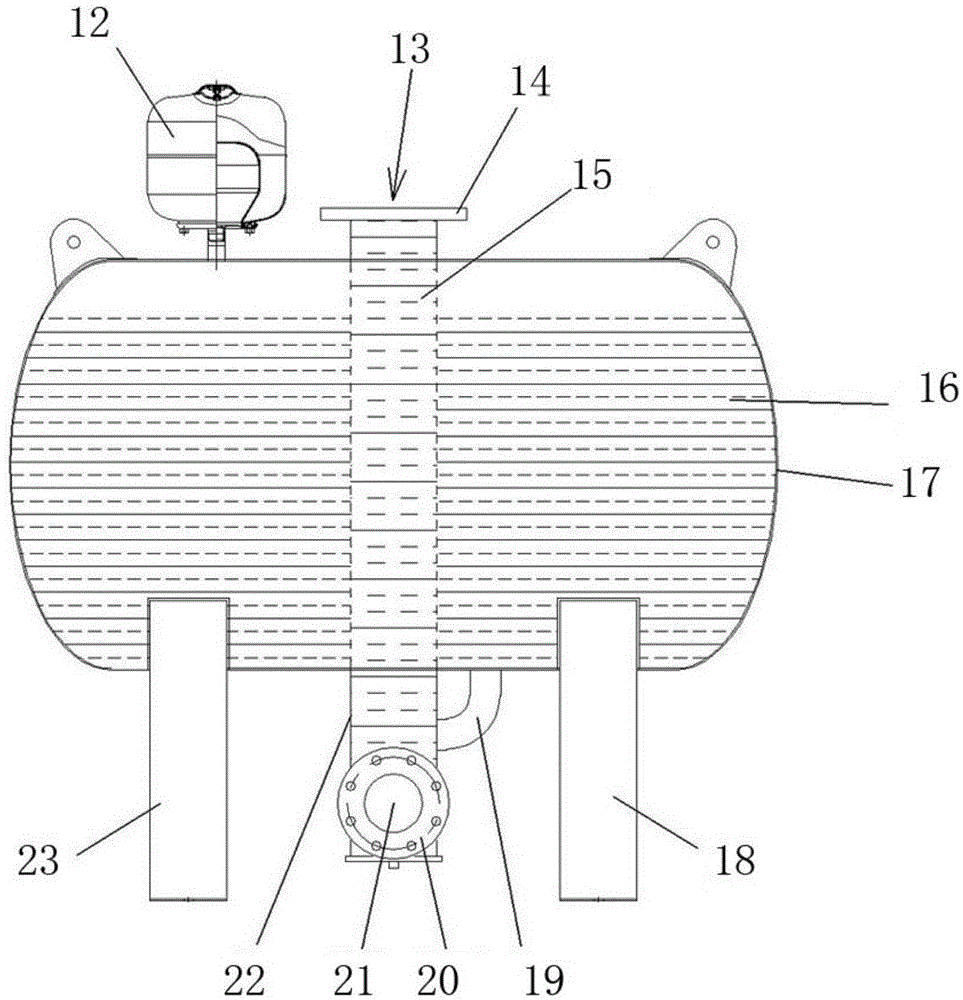

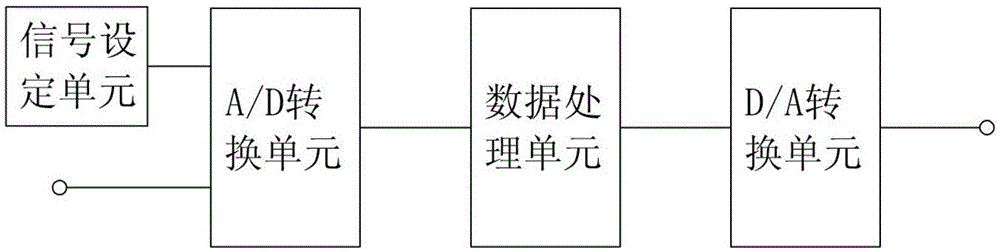

[0037] The permanent magnet synchronous motor constant pressure non-negative pressure water supply unit includes a steady flow tank, a pressure sensor and a negative pressure eliminator 12 are installed above the steady flow tank, and a water inlet 13 and a water outlet are also arranged on the steady flow tank. There is a negative pressure gauge at the end, and the water outlet is connected to a confluence main pipe I, and one side of the confluence main pipe I is provided with a confluence main pipe II, and the confluence main pipe I and the confluence main pipe II are connected through several branches arranged in parallel, and each branch There are water pumps and shut-off valves in series in the middle of the road, and the confluence main pipe II is connected to the water outlet of the user; the water pump includes a centrifugal pump with variab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com