Control loop of working device of engineering operation equipment

A technology of working device and control circuit, which is applied in the field of hydraulic circuit, can solve problems such as difficulties in the layout of engineering operation equipment, and achieve the effects of improving operating efficiency, saving energy, and reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

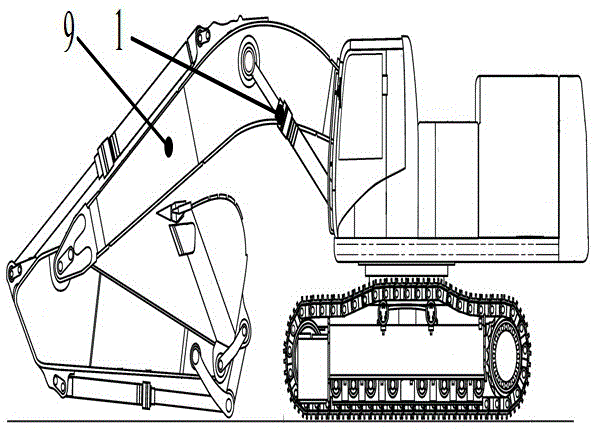

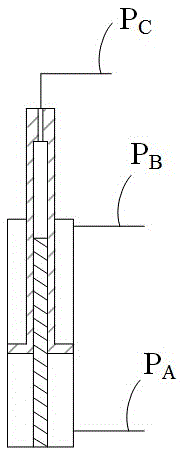

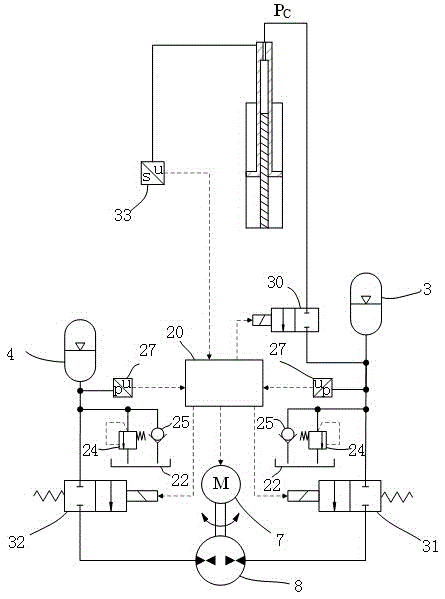

[0051] Such as Figure 7 As shown, in this embodiment, the working device 9 is driven by the boom hydraulic cylinder 1 to perform frequent up and down reciprocating movements. Boom hydraulic cylinder oil port P A It is connected to the high-pressure accumulator 3 via the first shut-off valve 30 . One working oil port of the hydraulic pump motor 8 is connected with the high-pressure accumulator through the second shut-off valve 31 , and the other working oil port is connected with the low-pressure accumulator 4 through the third shut-off valve 32 . The oil port of each accumulator is connected with a safety valve 24 and a check valve 25, wherein the high-pressure side of the safety valve is connected to the accumulator, the low-pressure side is connected to the oil tank 22, and the check valve is connected to the accumulator and the oil tank. The direction of fluid flow is from the tank to the accumulator. The hydraulic pump motor is driven by prime mover 7. Pressure sensor...

Embodiment 2

[0055] Such as Figure 8 As shown, in this embodiment, the liquid-pneumatic energy storage balance circuit is connected to the oil port P of the boom hydraulic cylinder 1 C ; The liquid-gas energy storage balance circuit includes a high-pressure accumulator 3, a safety valve 24 and a one-way valve 25, the high-pressure accumulator 3 is connected to the safety valve 24, and the safety valve 24 is connected to the oil tank 22, and the two oils of the safety valve 24 The port is connected with a one-way valve 25. The high-pressure accumulator is charged with high-pressure gas in advance to balance the working device and recover its potential energy. The drive circuit of the hydraulic cylinder adopts an open hydraulic circuit.

[0056] When the control signal is to lower the working device 9, the first controller coordinates and controls the four two-position two-way proportional valves 23 and the hydraulic pump 21 to drive the boom hydraulic cylinder to retract. When the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com