Mineral leaching device for membrane bioreactor combined ion exchange

A membrane bioreactor and ion exchange technology, applied in the direction of improving process efficiency, can solve the problems of low ore leaching efficiency, inconvenient parameter adjustment, poor controllability, etc., and achieve the goal of eliminating adverse effects, promoting rapid reproduction, and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

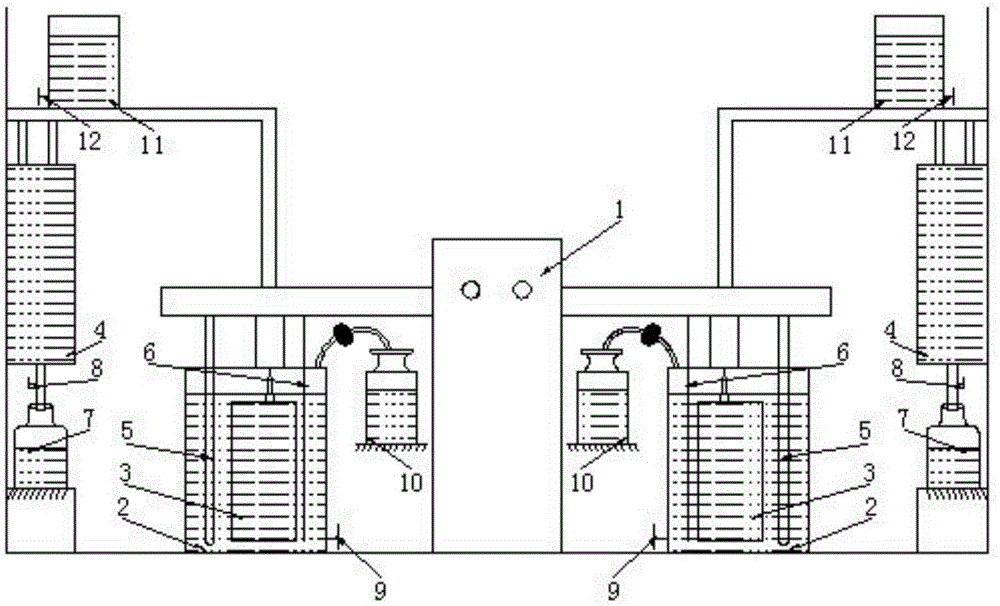

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, a membrane bioreactor combined ion exchange ore leaching device includes a control cabinet 1, a reaction tank 2, a membrane 3, an ion exchange column 4, a heating tube 5, an aeration tube 6, a metal ion collector 7, a washing Liquid collection or regeneration liquid control valve 8, reaction tank slag discharge valve 9, nutrient solution storage bottle 10, eluent liquid storage bottle 11 and eluent or regeneration liquid control valve 12; The reaction tank 2 is convenient for the two tanks to be used alternately. The reaction tank 2 is provided with a membrane 3, a heating pipe 5 and an aeration pipe 6; the bottom of the reaction tank 2 is provided with a reaction tank slag discharge valve 9; the bottom of the eluent storage bottle 11 is provided with an eluent control valve 12; The pipes of the exchange column 4 and the metal ion co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com