Box-type annealing furnace and annealing method using same

A box-type annealing furnace and annealing furnace technology, which is applied in the direction of improving process efficiency, can solve the problems of incomplete annealing, uneven temperature, and temperature of external heating system, and achieve stable and controllable heating and cooling rate, temperature control system Accurate and reliable, fast heating and cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

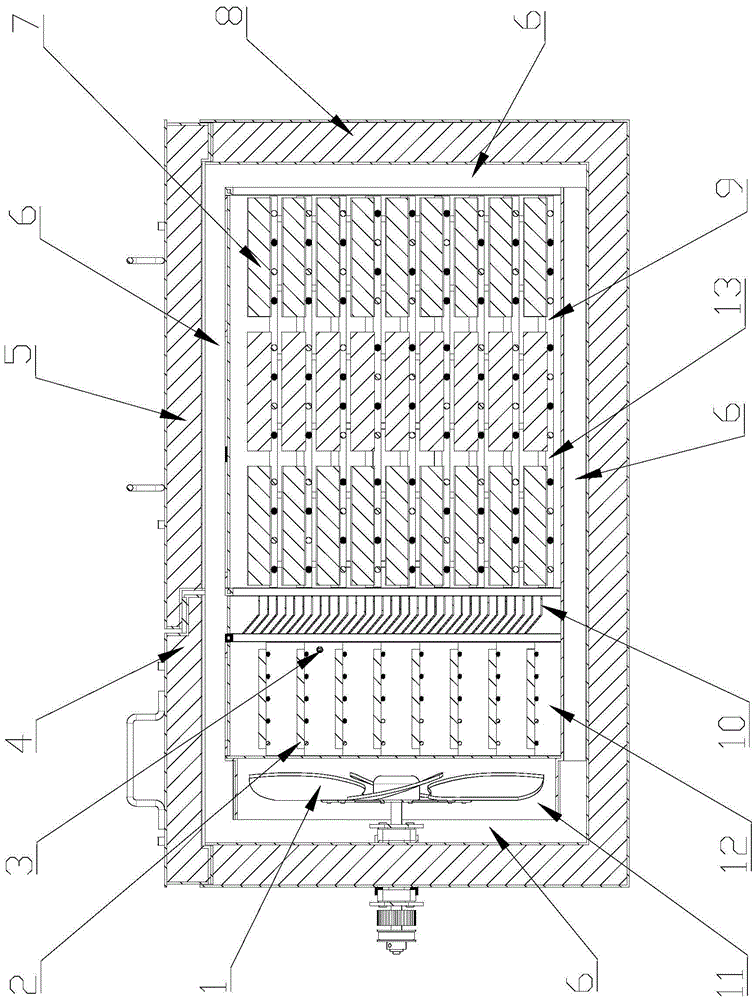

[0030] refer to Figure 1 to Figure 3 , the present invention is a box-type annealing furnace, comprising an annealing furnace body, a power chamber 11, a thermal chamber 12 and a workpiece chamber 13 are arranged in the annealing furnace body, a heating device is arranged in the thermal chamber 12, and a power chamber 11, a thermal The surroundings of the chamber 12 and the workpiece chamber 13 are provided with an air duct 6 for air circulation, and the power chamber 11 is provided with a turbulence device for disturbing the air flow. 6 to form a circulation channel.

[0031] This box-type annealing furnace and its annealing method are provided with a power chamber 11 which disturbs the airflow and sends air through the thermal chamber 12. A heating device is provided in the thermal chamber 12. After heating, the airflow passes through the workpiece chamber 13, and the airflow in the workpiece chamber 13 is heated. The workpiece is heated, and the air flow is reflowed throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com