Reverse micelle emulsion used for biological enzyme immobilization and biological enzyme immobilization method thereof

A technology of biological enzymes and reverse micelles, applied to biochemical equipment and methods, fixed on or in inorganic carriers, fixed on/in organic carriers, etc., can solve problems such as the reduction of biological enzyme activity, and achieve Avoid reduction, avoid loss, effect of high catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

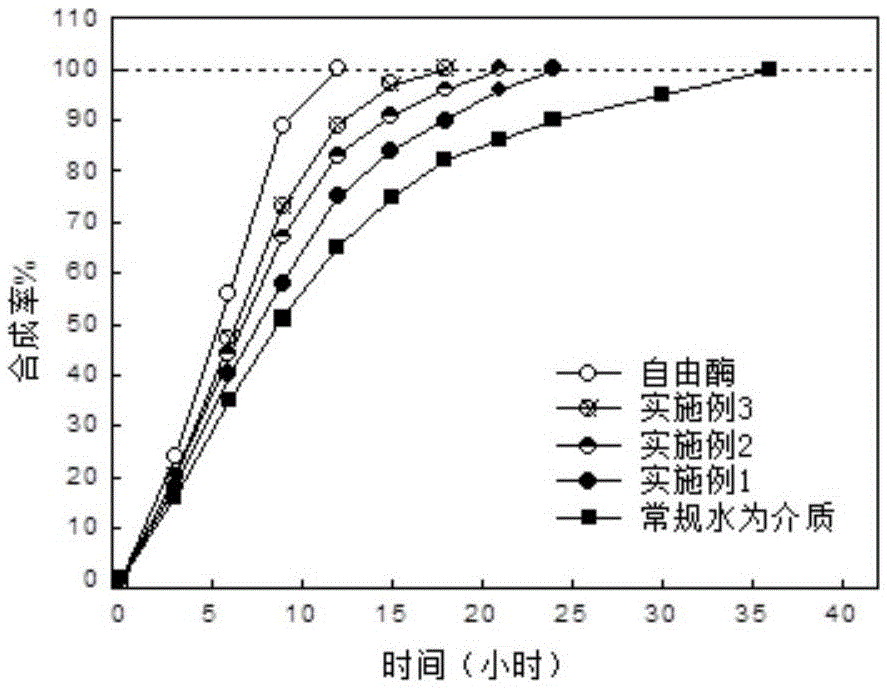

Embodiment 1

[0045] A reverse micellar emulsion for immobilizing biological enzymes, comprising the following components in parts by weight:

[0046] OP-10: 15 servings

[0047] n-octanol: 21 parts

[0048] Isooctane: 48 parts

[0049] Tris-HCl buffer: 0.5 parts

[0050] Distilled water: 3.5 parts.

[0051] This embodiment gives birth to the method for immobilizing biological enzyme, comprises the following steps:

[0052] 1), OP-10: 15 parts by weight, n-octanol: 21 parts by weight, isooctane: 48 parts by weight, Tris-HCl buffer solution: 0.5 parts by weight, distilled water: 3.5 parts by weight, mix and stir evenly to obtain a mixed Lotion;

[0053] 2), the mixed emulsion obtained in 1) is subjected to ultrasonic treatment to form a reverse micellar system; the intensity of the ultrasonic wave is 0.5KW / m 3 , the ultrasonic frequency is 18KHz, and the processing time is 2 hours;

[0054] 3), add 2 parts by weight of Candida lipase, nano Fe 3 o 4 10 parts by weight of magnetic par...

Embodiment 2

[0057] A reverse micellar emulsion for immobilizing biological enzymes, comprising the following components in parts by weight:

[0058] OP-10: 14 servings

[0059] n-octanol: 22 parts

[0060] Isooctane: 45 parts

[0061] Tris-HCl buffer: 0.8 parts

[0062] Distilled water: 3.2 parts.

[0063] This embodiment gives birth to the method for immobilizing biological enzyme, comprises the following steps:

[0064] 1), OP-10: 14 parts by weight, n-octanol: 22 parts by weight, isooctane: 45 parts by weight, Tris-HCl buffer solution: 0.8 parts by weight, distilled water: 3.2 parts by weight, mix and stir evenly to obtain a mixed Lotion;

[0065] 2), the mixed emulsion obtained in 1) is subjected to ultrasonic treatment to form a reverse micellar system; the intensity of the ultrasonic wave is 1.2KW / m 3 , the ultrasonic frequency is 40KHz, and the processing time is 0.5 hours;

[0066] 3), add 5 parts by weight of Candida lipase, nano Fe 3 o 4 10 parts by weight of magnetic p...

Embodiment 3

[0069] A reverse micellar emulsion for immobilizing biological enzymes, comprising the following components in parts by weight:

[0070] OP-10: 12 servings

[0071] n-octanol: 20 parts

[0072] Isooctane: 46 parts

[0073] Tris-HCl buffer: 0.8 parts

[0074] Distilled water: 3.2 parts.

[0075] This embodiment gives birth to the method for immobilizing biological enzyme, comprises the following steps:

[0076] 1), OP-10: 12 parts by weight, n-octanol: 20 parts by weight, isooctane: 46 parts by weight, Tris-HCl buffer solution: 0.8 parts by weight, distilled water: 3.2 parts by weight, mix and stir evenly to obtain a mixed Lotion;

[0077] 2), the mixed emulsion obtained in 1) is subjected to ultrasonic treatment to form a reverse micellar system; the intensity of the ultrasonic wave is 0.8KW / m 3 , the ultrasonic frequency is 30KHz, and the processing time is 1 hour;

[0078] 3), add 8 parts by weight of Candida lipase, nano Fe 3 o 4 10 parts by weight of magnetic part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com