Preparing method for mud stopping agent used for compound polycarboxylate superplasticizer

A composite polycarboxylic acid and water reducing agent technology, applied in the field of mud inhibitor, can solve the problems of poor performance of high mud content concrete, and achieve easy industrial production and quality control, good environmental adaptability, affinity good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

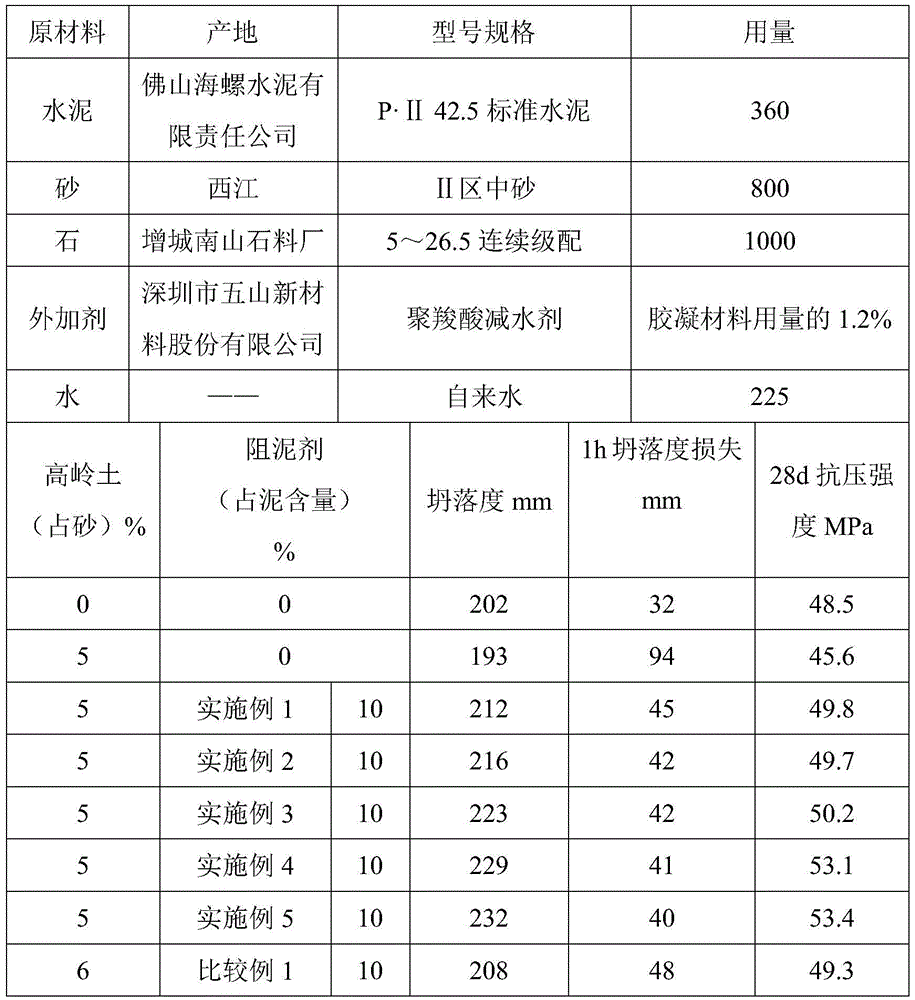

Examples

Embodiment 1

[0039] Mix 72g of butenol, 81g of dimethyl diallyl ammonium chloride, 5.54g of 30% hydrogen peroxide, 10.24g of ascorbic acid and 353g of water into the four-necked flask. The temperature was raised to 55° C., stirred for 4 h, and neutralized to pH=7 with 20% sodium hydroxide solution. Add 15.3 g of polymerized zirconium chloride with a molecular weight of 600-800 and a basicity of 50%-80% for compounding to obtain mud inhibitor 1 for a composite polycarboxylate water reducer.

Embodiment 2

[0041]17.8 g of acrylamide, 17.4 g of acryl alcohol, 105.3 g of dimethyl diallyl ammonium chloride, 0.74 g of ammonium persulfate, and 0.17 g of sodium bisulfite and 327.8 g of water were mixed into a four-necked flask. The temperature was raised to 55° C., stirred for 3.5 h, and neutralized to pH=7 with 50% sodium hydroxide solution. Add 42.1 g of polyaluminum chloride with a molecular weight of 600-800 and a basicity of 50%-80% for compounding to obtain mud inhibitor 2 for a composite polycarboxylate water reducer.

Embodiment 3

[0043] Mix 54g of methallyl alcohol, 145.8g of dimethyldiallylammonium chloride and 799.2g of water into a four-necked flask. The temperature was raised to 50 °C and stirred for 5 min. Dissolve 4.5g of sodium persulfate in 40.5g of water, 5g of ascorbic acid in 45g of water, add them dropwise within 2.5 hours, and continue the reaction for 1.5 hours after the addition is completed. and to pH=6. Add 40g of polymerized zirconium chloride with a molecular weight of 600-800 and a basicity of 50%-80% for compounding to obtain a mud inhibitor 3 for a composite polycarboxylate water reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com