Crystalline silicon solar cell secondary printing front face electrode overprinting screen printing plate graph structure

A crystalline silicon solar cell and secondary printing technology, applied in the field of solar cells, can solve the problems of DP2 electrode and DP1 electrode dislocation, battery conversion efficiency drop, electrode aspect ratio drop, etc., to improve alignment accuracy and comprehensive performance , the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods are provided, but the scope of protection of the present invention is not limited to the following the described embodiment.

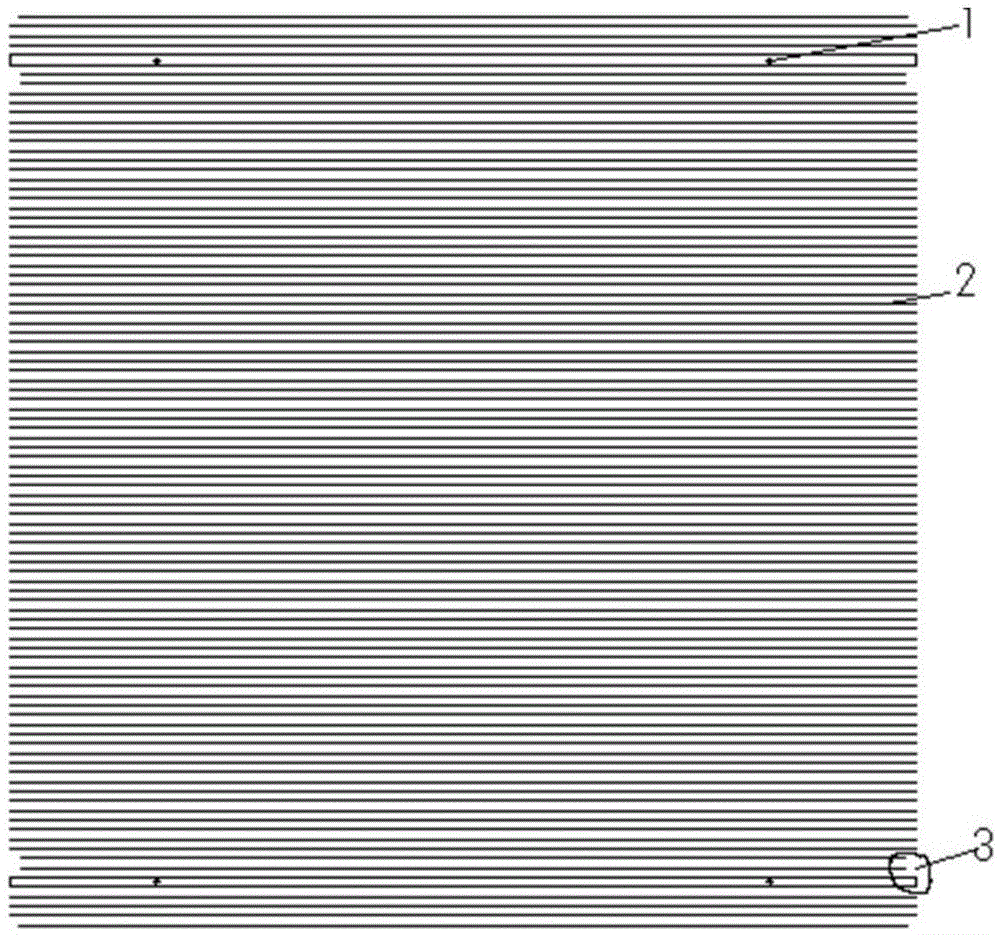

[0028] figure 1 Shown is the DP1 graphic in the secondary printing overprint screen graphic, including Mark point 1, sub-grid line 2 and characteristic graphic 3, wherein the number of Mark point 1 is more than 3, and the number of sub-grid lines 2 is Several sub-grid lines 2 are parallel to each other, Mark point 1 is located between two sub-grid lines, and feature figure 3 is located at the top of the 5th, 6th, 7th, and 8th sub-grid lines from both ends of the graphic.

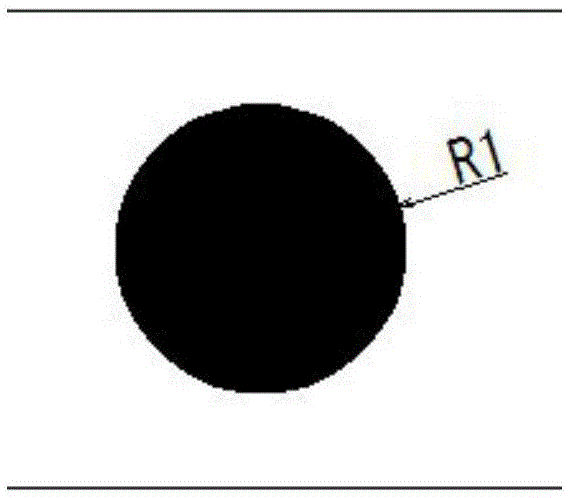

[0029] figure 2 It is an enlarged picture of Mark point 1 in the DP1 graphic. Mark ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com