Box folding machine of industrial packing assembly line

A packaging line, folding box machine technology, applied in packaging, transportation and packaging, container manufacturing machinery and other directions, can solve problems such as reduced efficiency, troublesome operation, waste of time, etc., to reduce manufacturing processes, save manufacturing time, and achieve fine-tuning and The effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

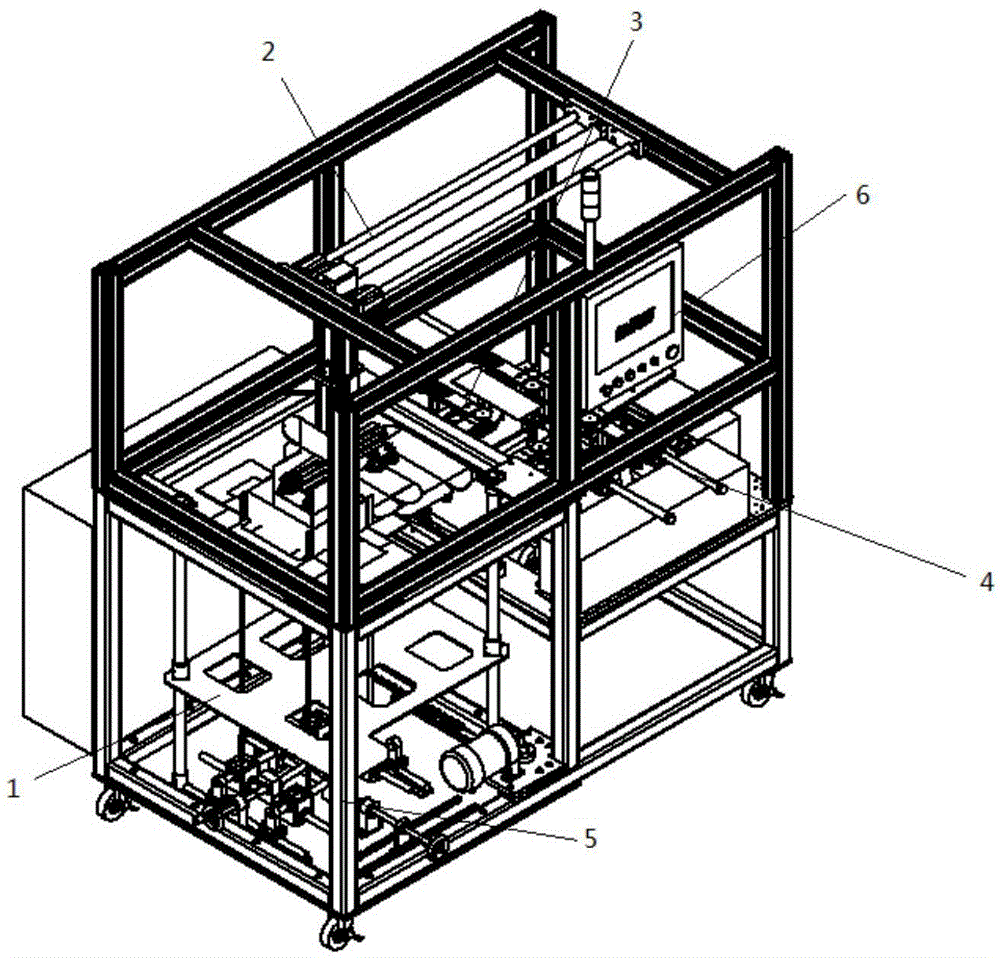

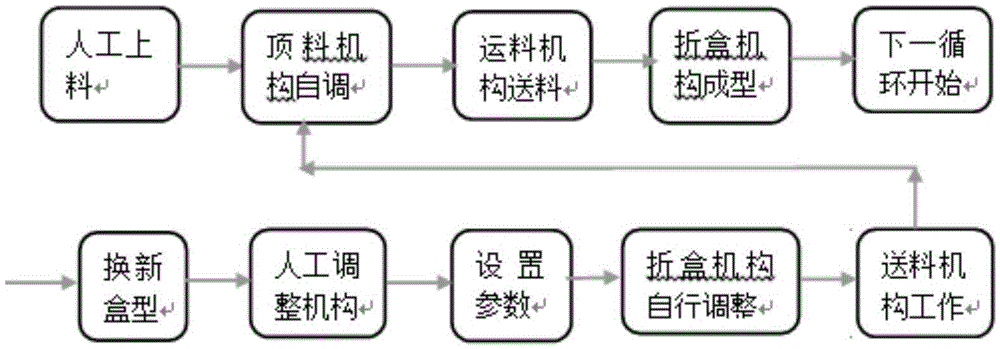

[0034] Such as figure 1 with figure 2 As shown, an industrial packaging assembly line box folding machine includes a material ejecting mechanism 1 , a material conveying mechanism 2 , a folding mechanism 3 , an adjusting mechanism 4 , a frame 5 and an electrical mechanism 6 .

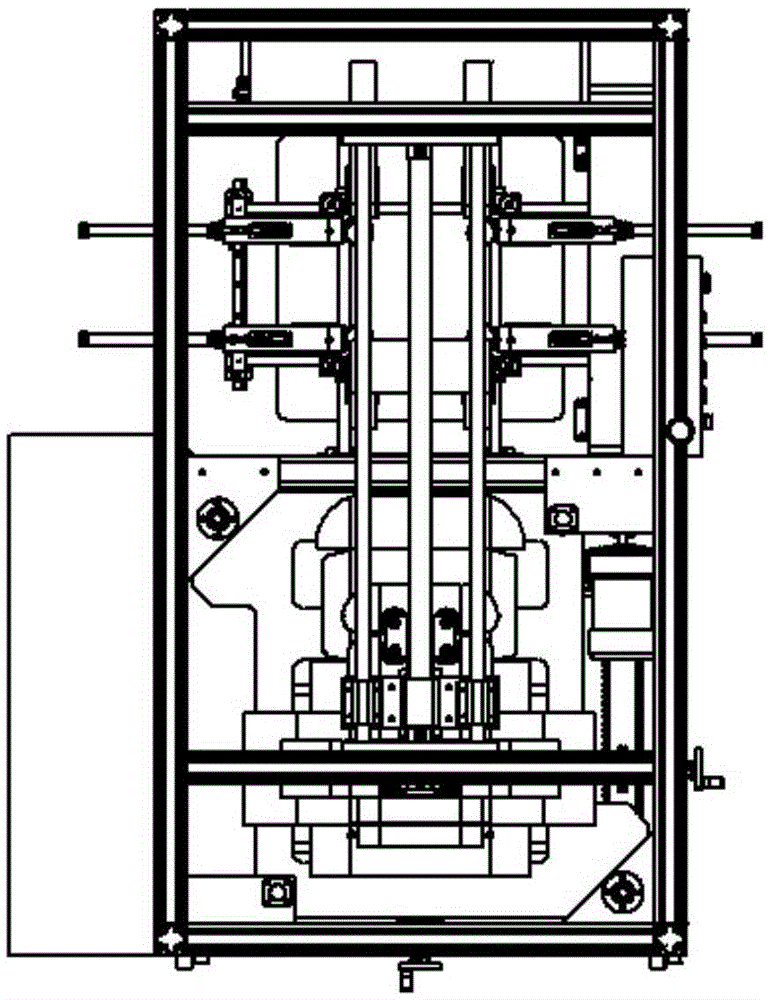

[0035] Such as Figure 4 As shown, the ejector mechanism 1 is mainly divided into a carton adjustment device and a fixed-height feeding device. The carton adjustment device is to adjust and position the carton stopper by turning the adjustment screw handwheel 14 when changing the carton, and to position the paper The size of the box, the fixed-height feeding device is automatic equidistant lifting, to realize the function of feeding less material;

[0036] The height-fixed feeding device includes a positioning block and a lifting motor 11, a T-shaped screw rod 12 and a lifting platform 13 connected in sequence. The positioning block is used to position the lifting height of the lifting platform 13. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com