A general-purpose automatic management machine and corresponding management method

A management machine and general-purpose technology, applied in sorting and other directions, can solve the problems of many detection and judgment errors, few sorting colors, low efficiency, etc., and achieve the effect of improving operating efficiency, improving detection accuracy, and adapting to a wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solution of the present invention will be further described in conjunction with the accompanying drawings.

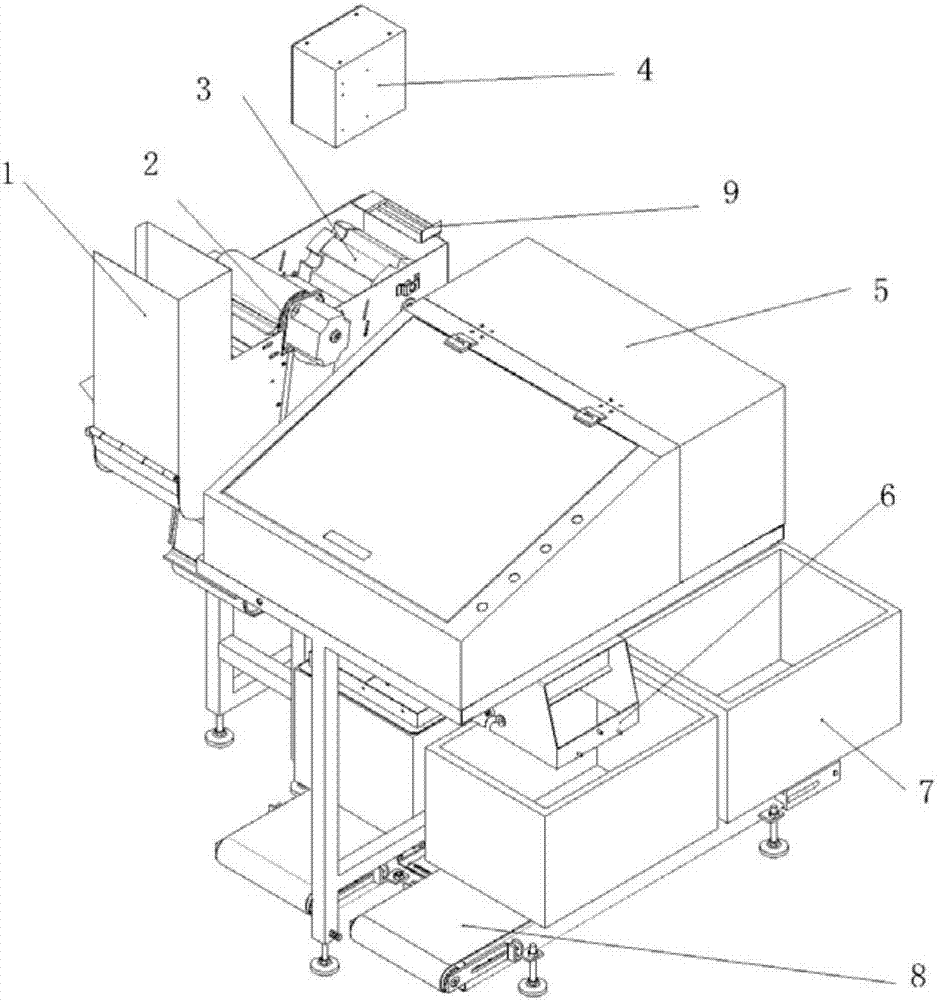

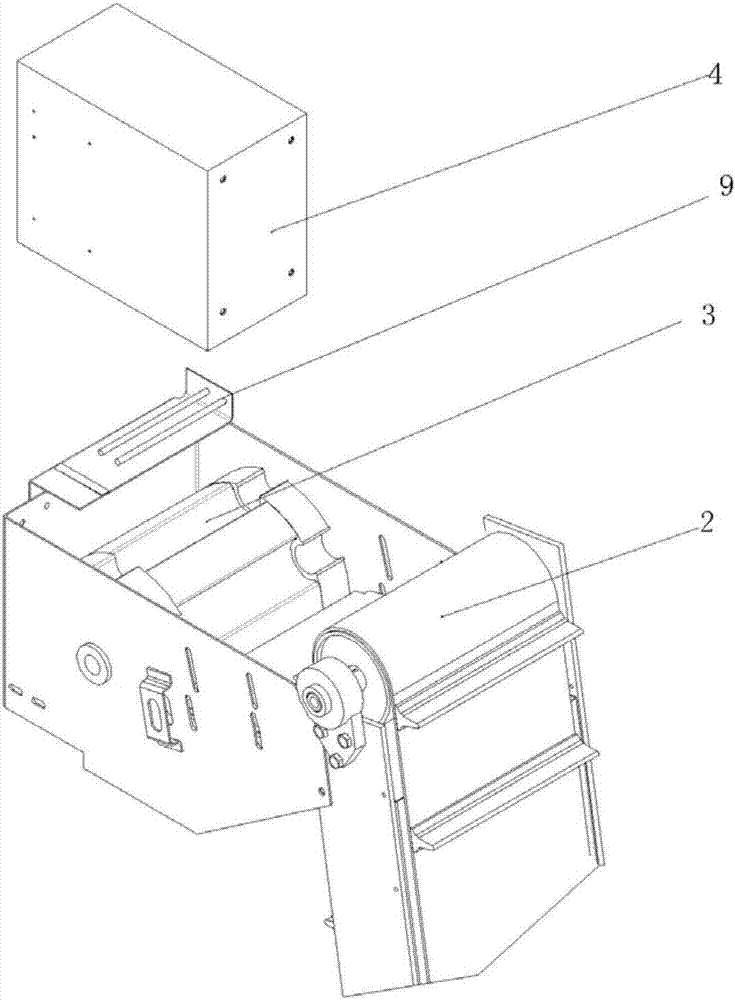

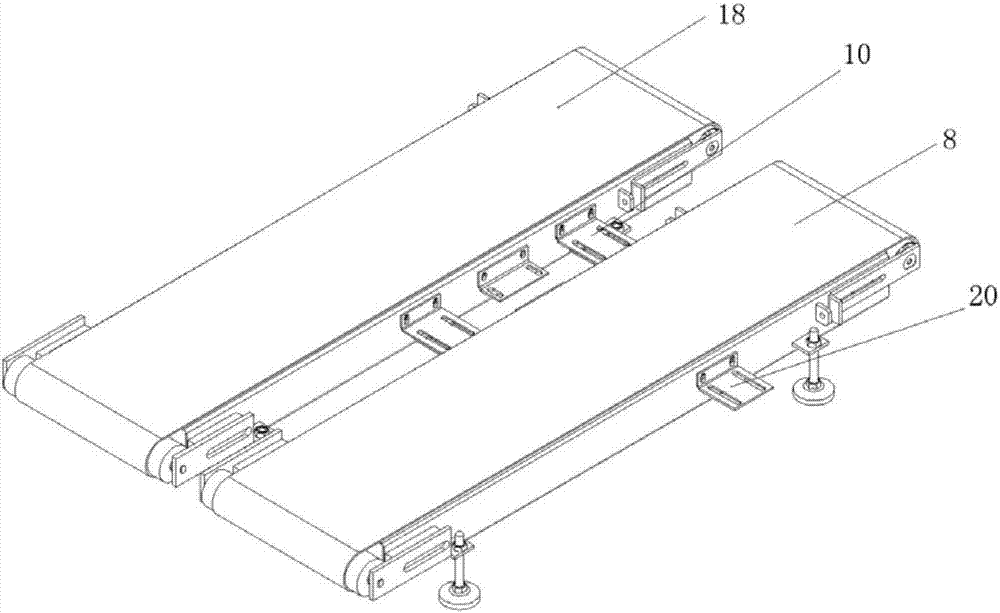

[0047] Such as figure 1 The automatic management machine shown includes a separation conveying mechanism (including a funnel mechanism 1, a lifting mechanism 2 and a separation detection roller 3), a detection mechanism (including a detection device 4 and a sample tube plate 9), a sorting mechanism 5, a rotating buffer Basket 6, collection basket 7 and control device (not shown in the figure). Preferably, in this embodiment, a collection basket delivery mechanism 8 is also included.

[0048] The function of the separation and conveying mechanism is to preliminarily organize the disordered bobbins output by the automatic winding machine, and then carry out subsequent detection and sorting one by one. In this embodiment, the separation and conveying mechanism includes a funnel mechanism 1, a lifting mechanism 2 and a separation detection roller 3. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com