Polyurea spraying equipment and spraying method and corresponding polyurea composite waterproof layer mechanism

A technology of spraying equipment and waterproof layer, which is applied in the direction of coating, liquid coating device on the surface, spraying device, etc. It can solve the problems of only intermittent suction, intermittent spraying, difficult operation, difficult operation, etc., to achieve The spraying method is simple and easy, highlighting the effect of self-healing performance and scientific structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

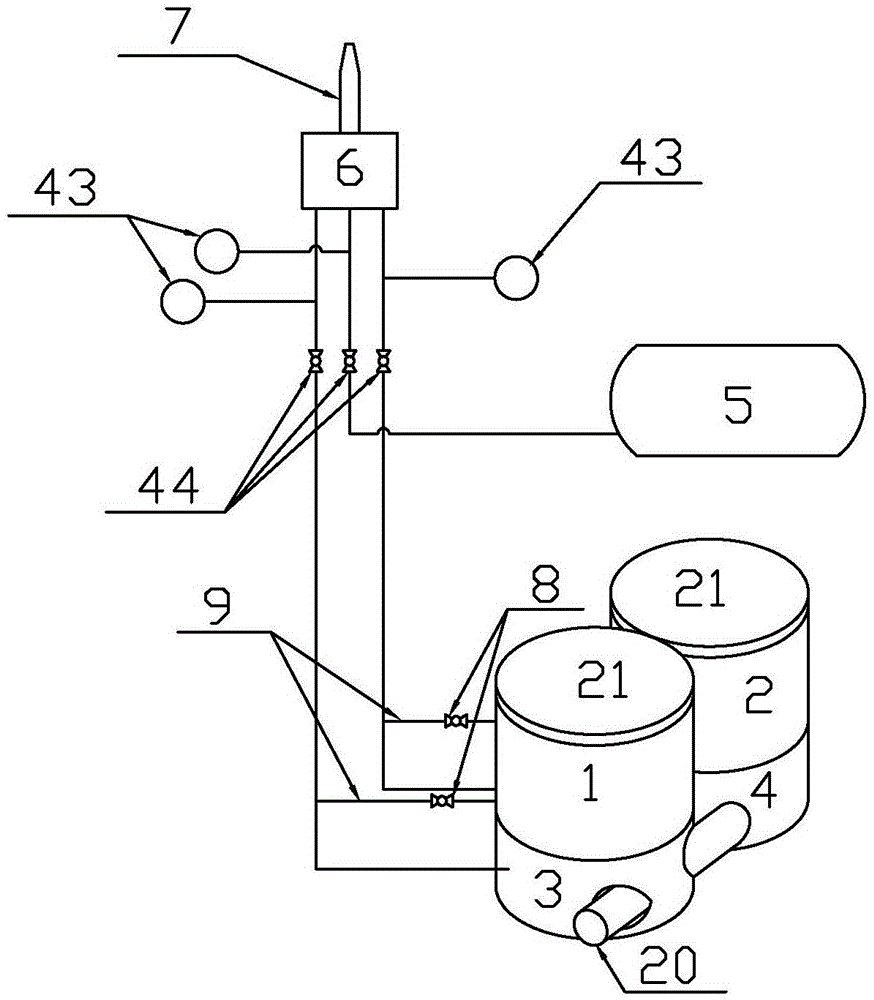

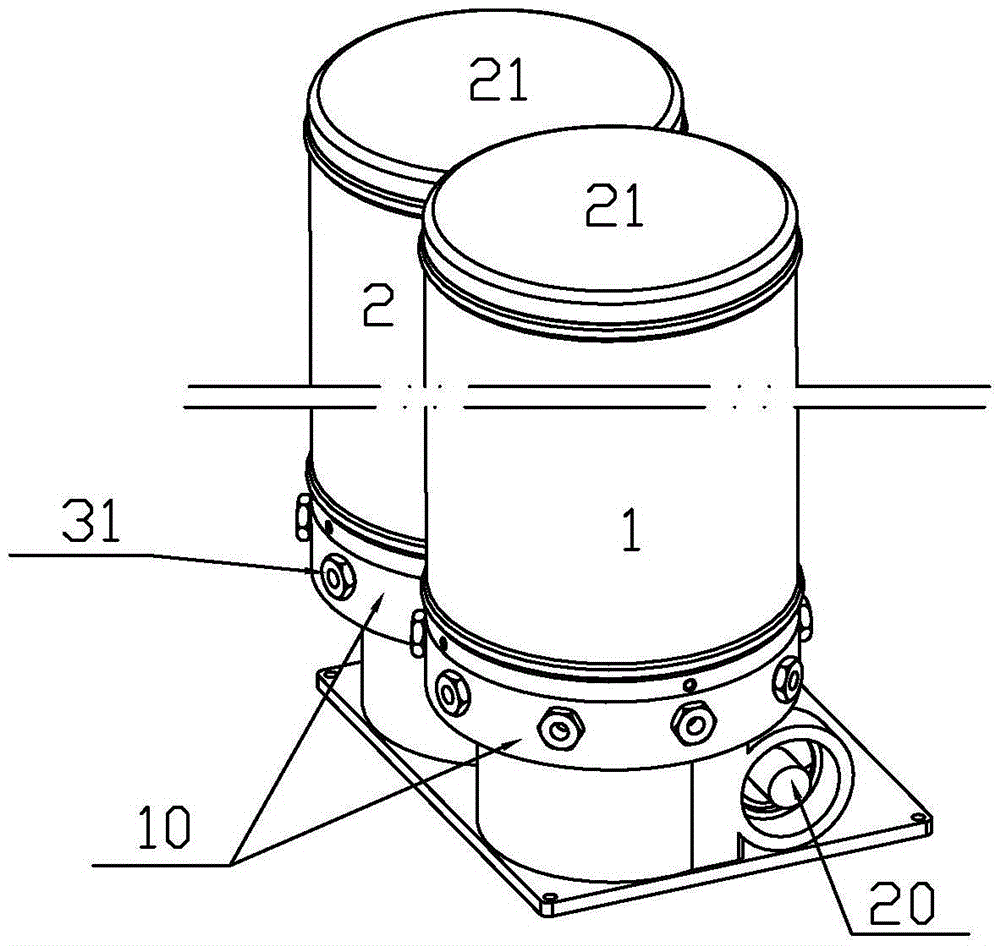

[0054] Implementation mode one: if Figure 2-9 As shown, the polyurea spraying equipment includes A material tank 1, B material tank 2, A material lifting pump 3, B material lifting pump 4, compressed air tank 5 and spray gun 6. The A lifting pump 3, the B lifting pump 4, and the compressed air tank 5 are respectively provided with an inlet and an outlet, and the spray gun 6 is provided with three inlets and a nozzle 7, and the three inlets are respectively connected with the A lifting pump 3 through a hose. The outlet of B, the outlet of B lifting pump 4 and the outlet of compressed gas tank 5 link to each other.

[0055] Such as figure 2 As shown, the inlet of A lifting pump 3 and the inlet of B lifting pump 4 are respectively connected to A material barrel 1 and B material barrel 2; the inlet of compressed air tank 5 is connected to a compressed air source or an air compressor (not shown in the figure) ), A and B lifting pumps 1 and 2 are equipped with a return regulatin...

Embodiment approach 2

[0065] Implementation mode two: if Figure 10-13 As shown, the outlet holes at the outer ends of each plunger chamber 11 are interconnected by passages 32 . Each plunger cavity 11 is a stepped hole with a large outside and a small inside. Each plunger cavity 11 is fixed with a plunger sleeve 28, and the plungers 12 are inserted in the inner end of the plunger sleeve 28 one by one. The outer end of the plunger sleeve 28 is also provided with an outlet hole and a one-way valve mechanism 29. Under the control of the one-way valve mechanism 29, the outlet hole is unidirectionally connected with the outlet hole at the outer end of the corresponding plunger chamber 11.

[0066] The middle section of the plunger sleeve 28 has an inlet hole opposite to the feed hole 13 of the corresponding plunger chamber 11, a circular boss 30 is arranged between the inlet hole and the outlet hole, and a circular boss 30 is arranged on the outlet hole at the outer end of each plunger chamber 11. The...

Embodiment approach 3

[0069] Implementation mode three: if Figure 14 As shown, an anti-deviation device is also provided on the flexible pipe between the A and B lifting pumps 3, 4 and the spray gun 5, and the anti-deviation device includes a hollow housing 33, and the middle of the hollow housing 33 One side is provided with fixed dividing plate 34, and the other side is provided with movable dividing plate 35, and the opposite surface end between movable dividing plate 35 and fixed dividing plate 34 all has arc-shaped notch, is sandwiched between the two. Rotating seal column 36, fixed dividing plate 34, turnable sealing column 36 and movable dividing plate 35 divide the interior of hollow housing 33 into a left secret chamber and a right secret chamber which are not communicated with each other. A chute is formed on the opposite side, and the movable partition 35 is arranged in the chute, and is equipped with a knob 46 for adjusting the clamping degree of the movable partition. By adjusting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com