Magnetic solid-phase extraction material and preparation method and application thereof

An extraction and magnetic solidification technology, applied in chemical instruments and methods, preparation of test samples, and other chemical processes, can solve problems such as poor dispersion, lack of dispersion, and poor stability, and achieve cheap and easy-to-obtain raw materials. Simple preparation method and high dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present application will be further described below in conjunction with specific embodiments.

[0033] The preparation method of aminosilanized magnetic nano-carbon spheres comprises the following steps:

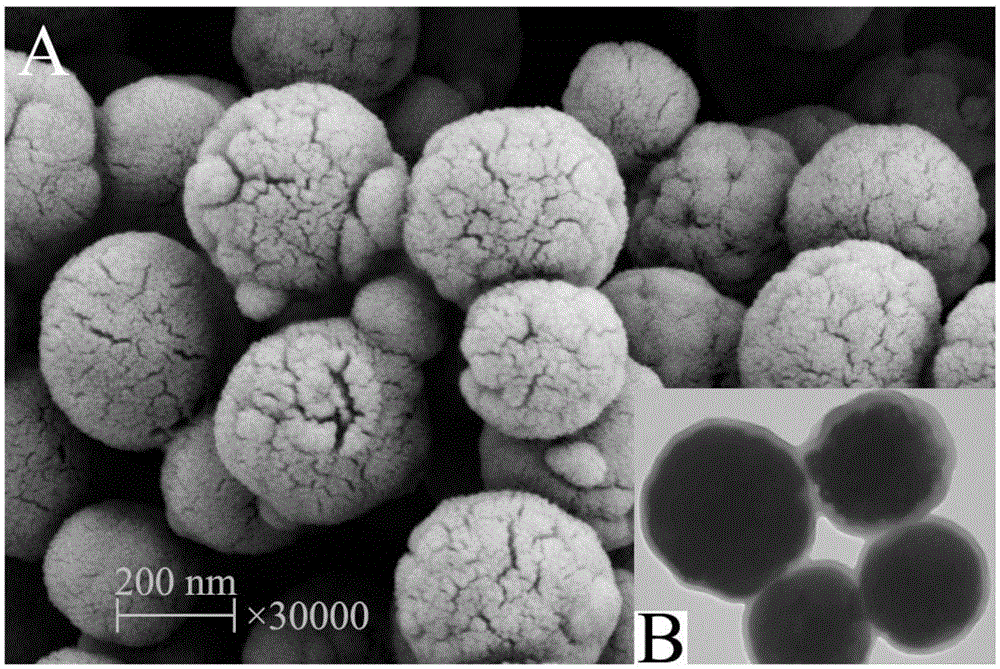

[0034] 1) Preparation of aminosilanized magnetic carbon nanospheres

[0035] The raw materials of ferric trioxide and ferric ferric oxide magnetic nano-carbon spheres for the preparation of this new material were synthesized according to the method reported in the literature, but some modifications were made: 1.35g of ferric chloride hexahydrate was accurately weighed and added to In a beaker of 75ml of ethylene glycol, stir until completely dissolved, then add 3.6g of sodium acetate (NaAc), and continue stirring until NaAc is completely dissolved. Then the solution was transferred to a 100ml polytetrafluoroethylene-lined cup, ultrasonically treated for 5 minutes, put into a stainless steel reaction kettle and tightened, and then placed in an oven at 200°C for 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com