A kind of nitromethane continuous reactor

A nitromethane and reactor technology is applied in the field of nitromethane continuous reactors to achieve the effects of improving product yield, improving selectivity and reducing back-mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

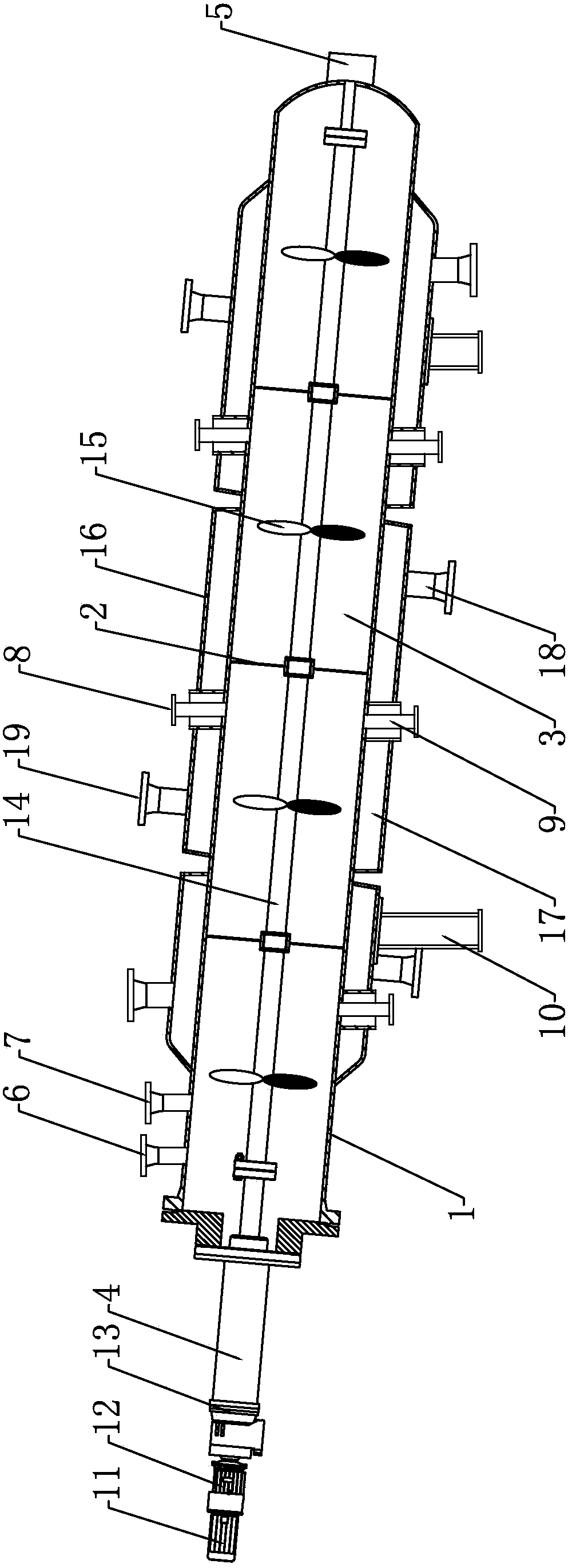

[0019] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown in , this embodiment includes a horizontal reactor shell 1 arranged obliquely, the cavity of the horizontal reactor shell 1 is divided into several interconnected reaction units 3 by several baffles 2, In the cavity of the horizontal reactor shell 1, along the axial direction of the horizontal reactor shell 1, a stirring mechanism that runs through each reaction unit 3 is provided, and the front end of the stirring mechanism passes through the horizontal reactor shell 1. The side wall of the head end is connected to a driving mechanism through the first mechanical seal seat 4, and the rear end of the stirring mechanism passes through the tail end side wall of the horizontal reactor shell 1 and connects to the horizontal re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com