A heat-sensitive material protection agent, thiourea dioxide mother liquor evaporation treatment method and system

A technology of sulfur dioxide and treatment method, which is applied in multi-effect evaporation, evaporator accessories, organic chemistry and other directions, can solve the problems of high cost, small production scale, unsuitable for popularization and application, etc., and achieves low cost, difficult to deal with and good economy Effects of benefits and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

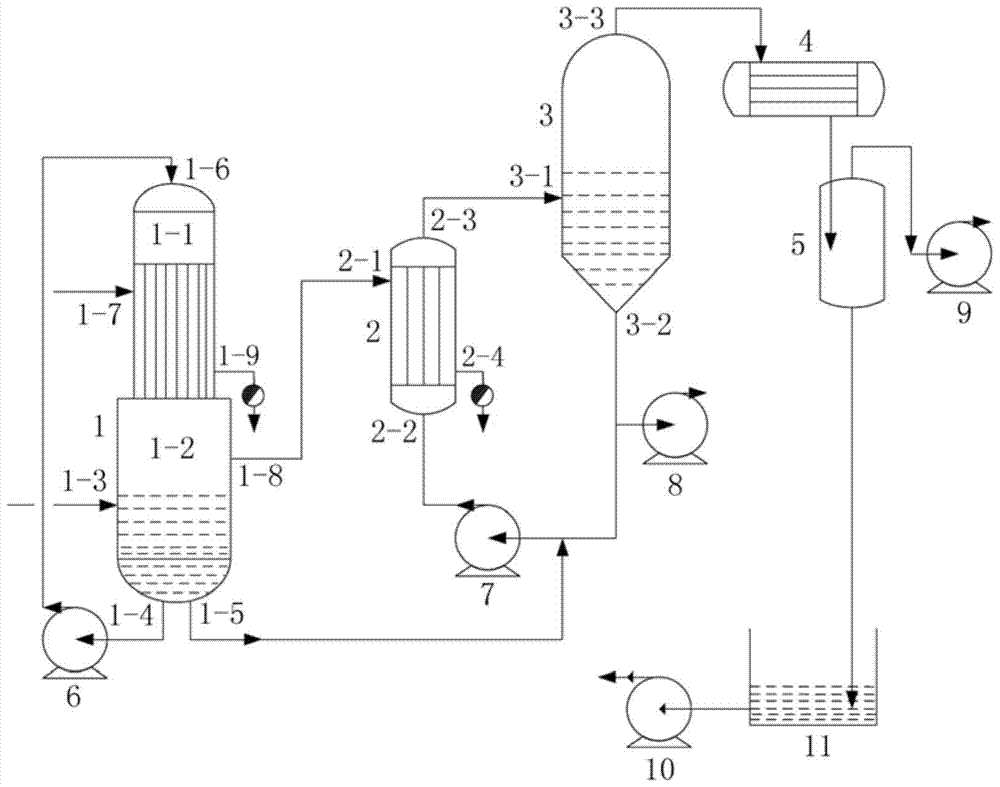

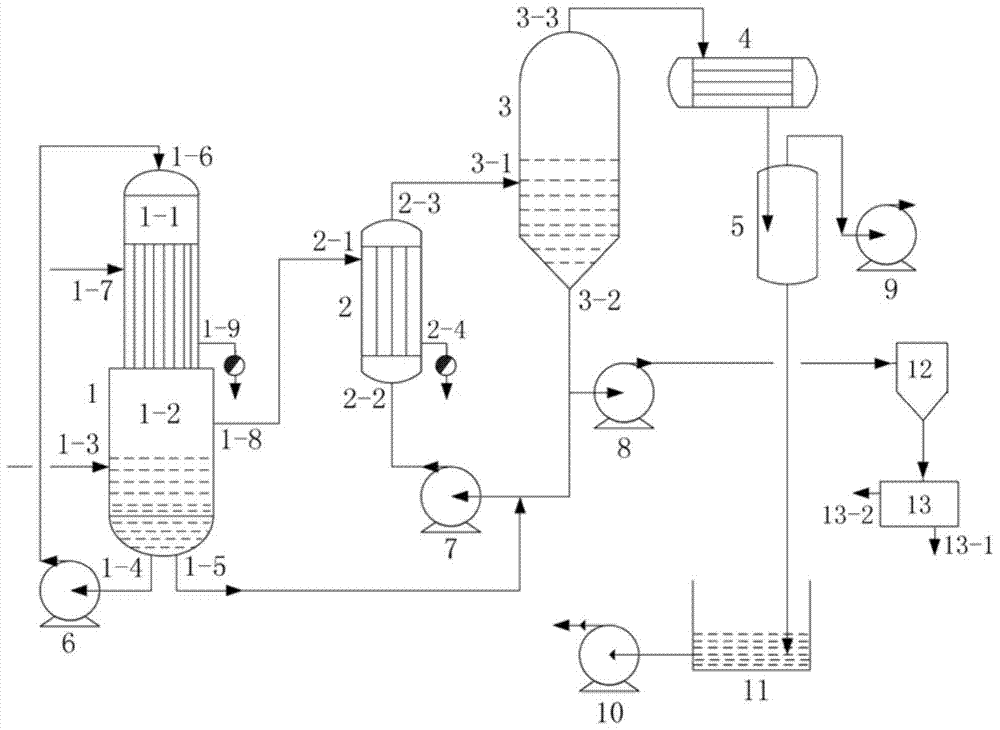

Image

Examples

Embodiment 1

[0034] The heat-sensitive material protection agent of this embodiment is composed of the following components in parts by weight: 0.3 part of hydroxyethylidene diphosphonic acid, 0.2 part of aminotrimethylene phosphonic acid, and 0.04 part of hexamethylenediamine tetramethylene phosphonic acid.

[0035] The preparation method of the heat-sensitive material protection agent is obtained by mixing the above-mentioned components according to the formula quantity.

Embodiment 2

[0037] The heat-sensitive material protection agent of this embodiment is composed of the following components in parts by weight: 0.5 part of hydroxyethylidene diphosphonic acid, 0.1 part of aminotrimethylene phosphonic acid, and 0.03 part of hexamethylenediamine tetramethylene phosphonic acid.

[0038] The preparation method of the heat-sensitive material protection agent is obtained by mixing the above-mentioned components according to the formula quantity.

Embodiment 3

[0040]The heat-sensitive material protection agent of this embodiment is composed of the following components in parts by weight: 0.2 part of hydroxyethylidene diphosphonic acid, 0.3 part of aminotrimethylene phosphonic acid, and 0.05 part of hexamethylenediamine tetramethylene phosphonic acid.

[0041] The preparation method of the heat-sensitive material protection agent is obtained by mixing the above-mentioned components according to the formula quantity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com