A pressing roller with radially stretchable pressing roller sheets

A technology of suppressing rollers and spacers, which is applied in the field of suppressing rollers, can solve problems affecting the uniformity of sowing and yield, affecting the uniformity of compaction, the position of seeds in shallow operations and the thickness of covering soil, etc., to reduce soil adhesion and ensure Operational stability and the effect of ensuring the uniformity of sowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

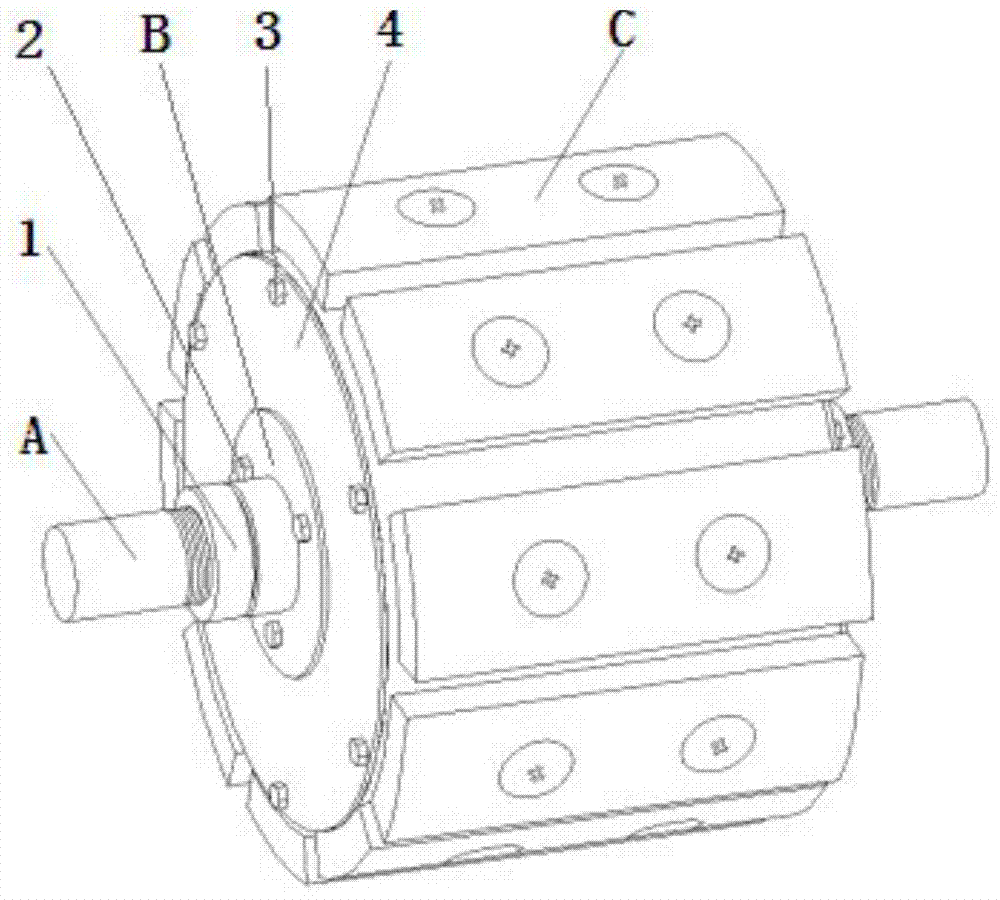

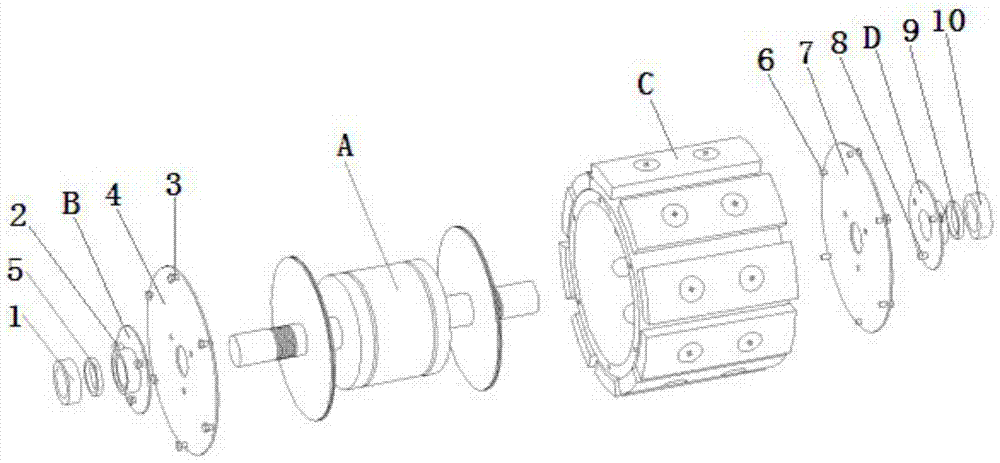

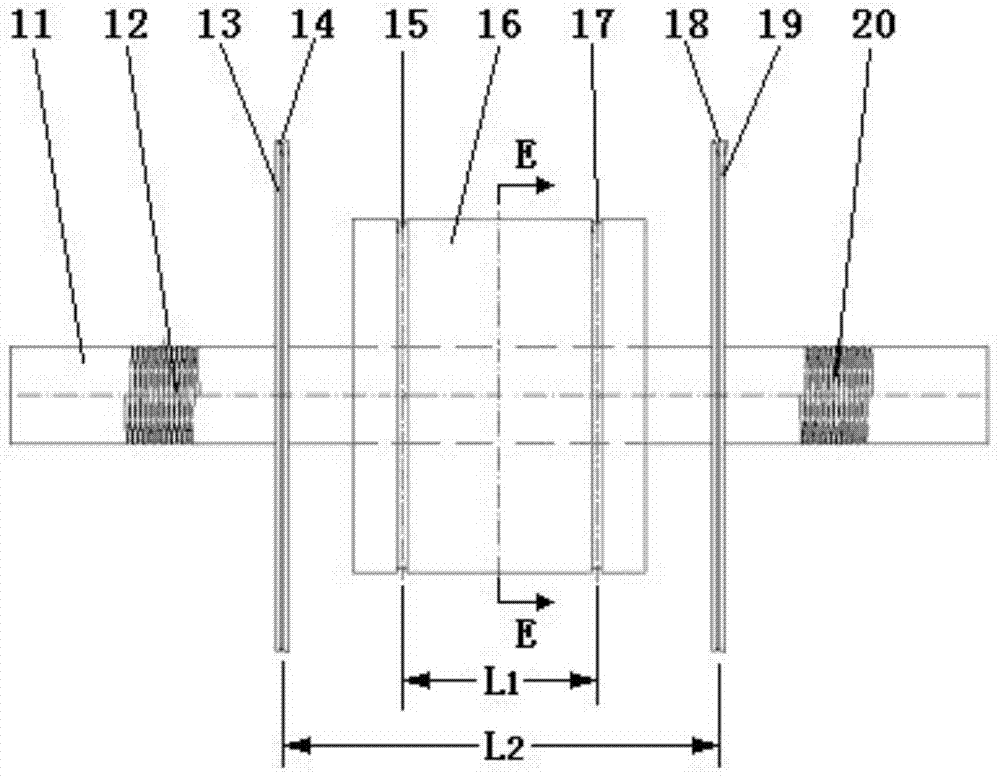

[0030] Such as figure 1 and figure 2 As shown, the present invention consists of camshaft assembly A, bearing assembly IB, pressure roller assembly C, bearing assembly IID, nut I1, screw group I2, screw group II3, end cover I4, gasket I5, screw group III6, end cover II7 , screw group Ⅳ8, gasket Ⅱ9, and nut Ⅱ10, wherein the inner roller 32 of the pressure roller assembly C is set on the camshaft assembly A, and the top ends of the ball heads 37 of a row of n connecting pieces 30 in the pressure roller assembly C are connected with the camshaft assembly The oil passage II15 in A is slidably connected, and the tops of the ball joints 37 of another row of n connectors 30 in the pressure roller assembly C are slidably connected with the oil passage III17 in the camshaft assembly A.

[0031] End cover I4, bearing assembly IB, gasket I5 and nut I1 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com