Paddy field rotary tiller leveling system

A rotary tiller and leveling technology, which is applied to agricultural machinery and implements, shovels, plows, etc., can solve the problems of limited leveling precision, non-adjustable position, affecting field leveling precision, etc., so as to improve leveling precision, improve leveling effect, and facilitate the The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

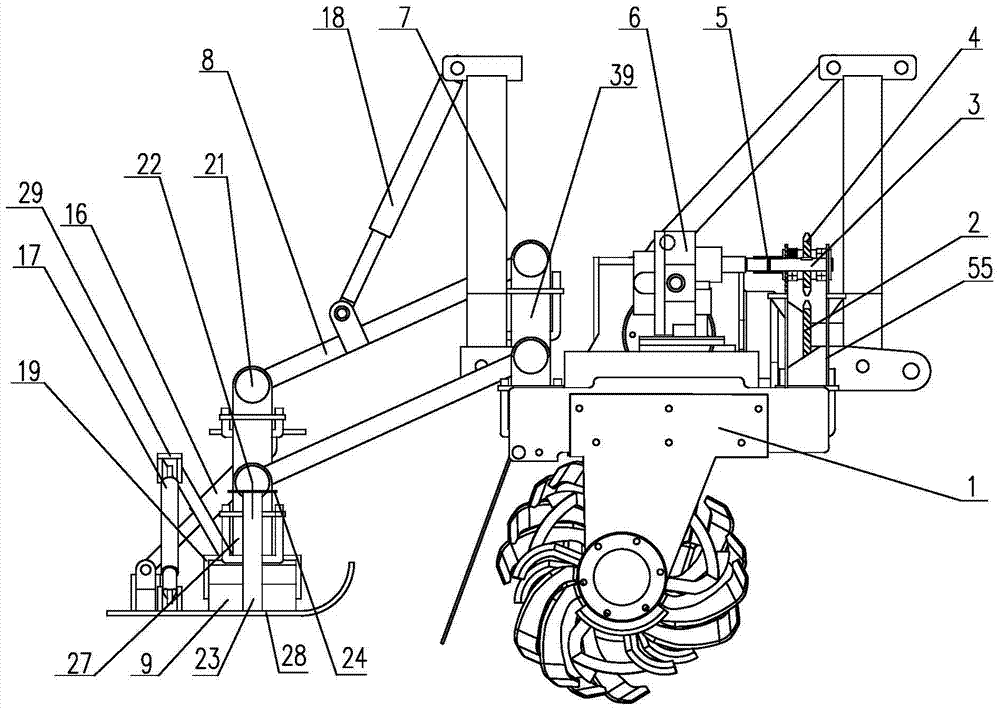

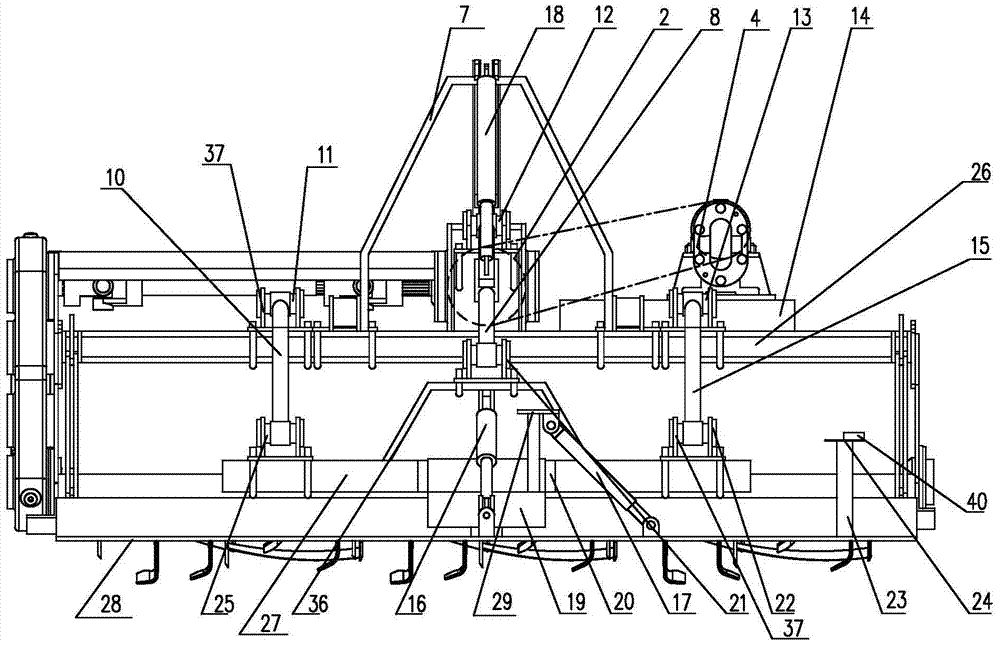

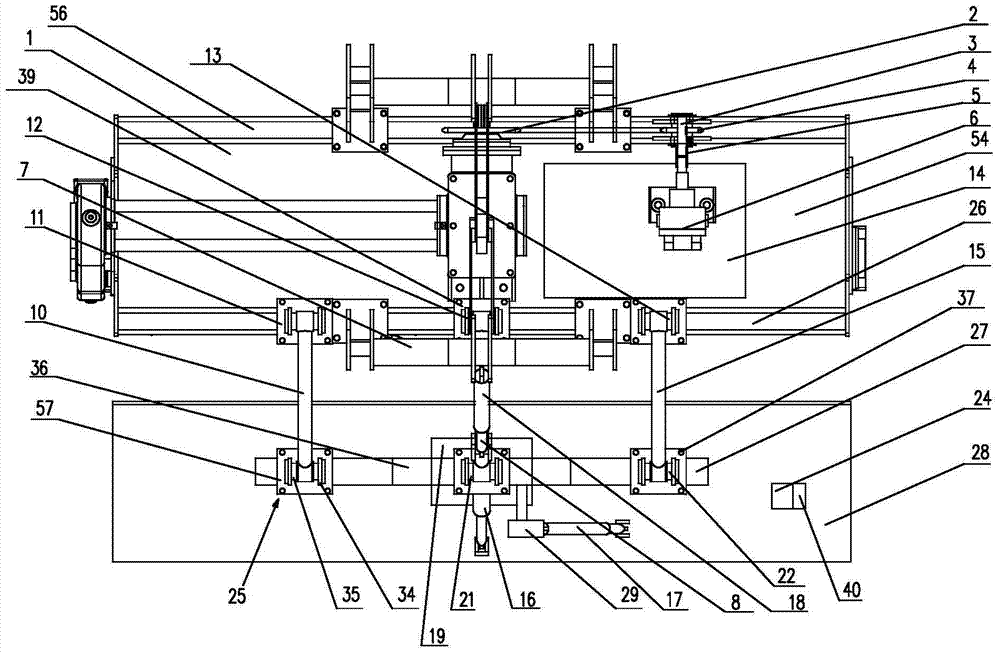

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0020] A paddy field rotary tiller leveling system provided by the invention, such as Figure 1-8 As shown, it includes a left pull rod 10, a middle pull rod 8, a right pull rod 15, a leveling unit, a drive unit, a hydraulic operating mechanism for controlling the leveling unit, and a controller 24 for controlling the hydraulic operating mechanism, wherein the The flat ground unit comprises a flat ground support plate 28, a cross movable connection device 19, a suspension bracket 36 and a crossbeam 27, and the cross movable connection device 19 includes a front cover 30, a rear cover 33, and is connected to the front cover 30 and the rear cover 33 The upper cover plate 38 between the top ends, the upper through hole 32 arranged on the upper cover plate 38, the lower rotating shaft 31 arranged between the front cover plate 30 and the inner surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com