Liquid crystal display device

A technology of liquid crystal display device and liquid crystal layer, which can be applied in the fields of instruments, nonlinear optics, optics, etc., and can solve problems such as difficulty in using "view angle compensation plate integrated polarizing plate, unfavorable cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

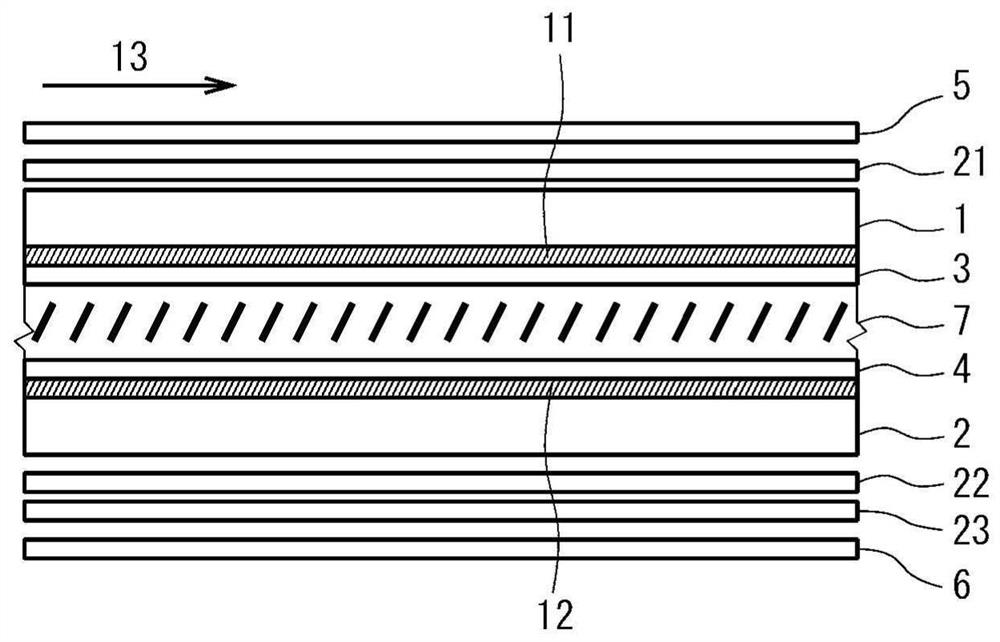

[0057] ·Is the above figure 1 , 2 In the structure shown in , a TAC film as a protective film of the polarizing plate is disposed between the polarizing layer of the polarizing plate and the optical plate

[0058] ·Liquid crystal layer thickness: 4μm

[0059] ·Liquid crystal material: △n=0.0914, △ε=-5.1, no chiral material added

[0060] ・Pretilt angle: 89.5 degrees (the first substrate and the second substrate both have this pretilt angle)

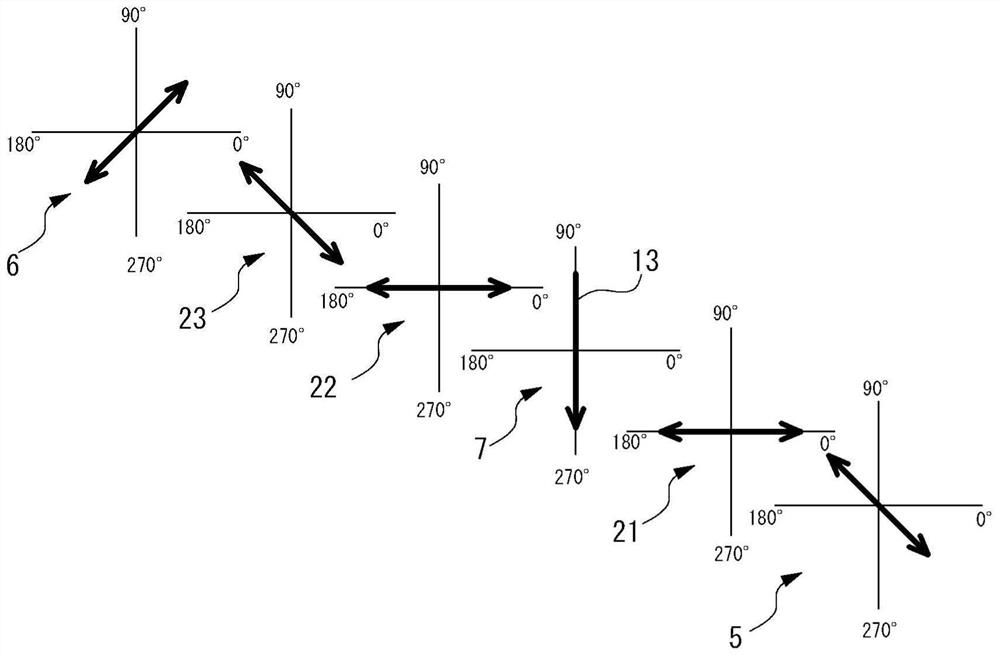

[0061] ・Alignment direction at the center of the layer thickness direction of the liquid crystal layer when a voltage is applied: 6 o'clock direction (270° direction)

[0062] 1 / 4 wavelength plate: a retardation plate with an in-plane retardation of 140nm and positive uniaxial optical anisotropy (positive A plate)

[0063] ・Optical plate: Negative biaxial film with in-plane retardation of 55nm and thickness direction retardation of 220nm

[0064] Light source: standard light source D65

[0065] ・Emulator: Liquid crystal display emul...

Embodiment 2

[0067] ·Is the above figure 1 , 2 In the structure shown in , no TAC film, etc. as a protective film of the polarizing plate is placed between the polarizing layer of the polarizing plate and the optical plate

[0068] ·Other conditions are identical with embodiment 1

Embodiment 3

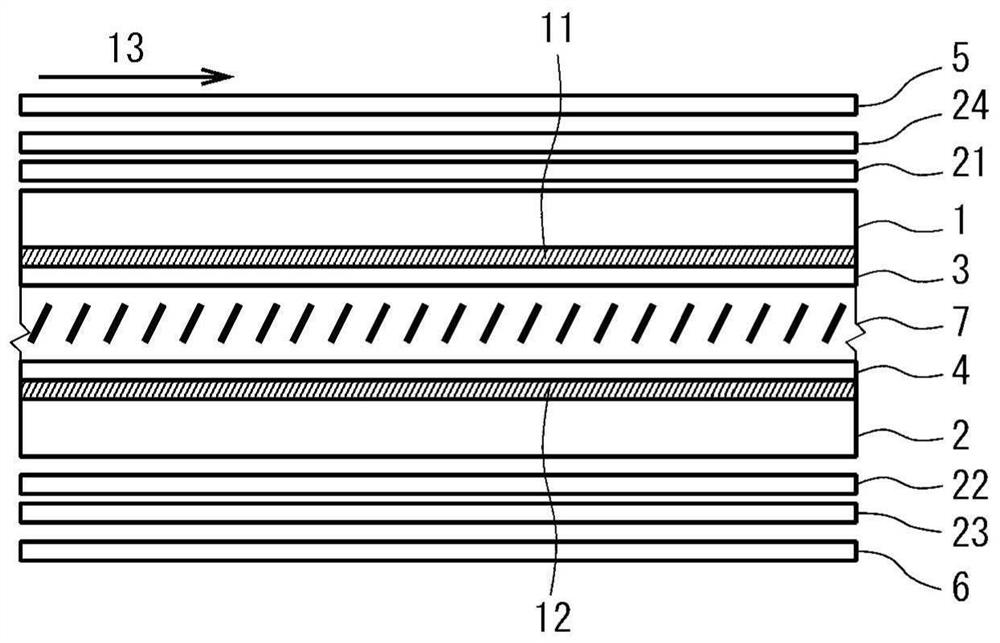

[0070] ·Is the above image 3 , 4 In the structure shown in , no TAC film, etc. as a protective film of the polarizing plate is placed between the polarizing layer of the polarizing plate and the optical plate

[0071] ・Optical plate: Negative biaxial film with in-plane retardation of 55nm and thickness direction retardation of 124nm

[0072] ·Other conditions are identical with embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com