Subdivision water-saving and fog-dissipating closed cooling tower

A closed cooling tower technology for eliminating fog, which is applied in the field of cooling towers and can solve the problems of water consumption and excessive consumption of water resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

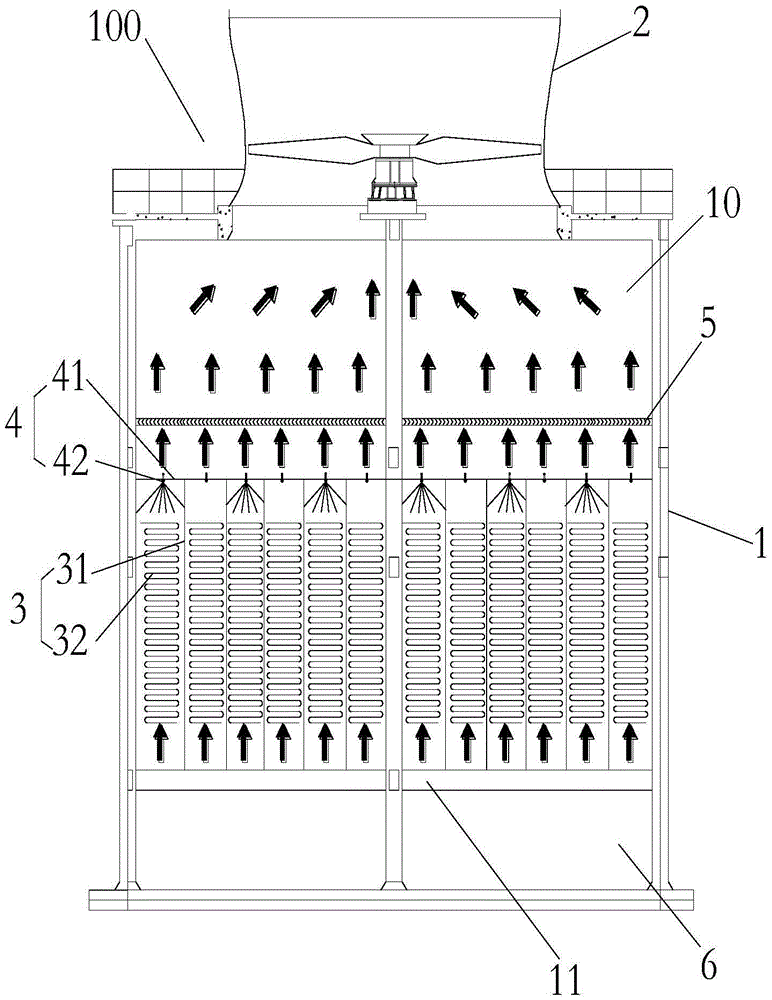

[0024] refer to figure 1 , a sub-unit water-saving and fog-eliminating closed cooling tower described in this embodiment includes a cooling tower body 1 having an air mixing chamber 10, and the cooling tower body 1 is provided with a cooling tower body communicating with the air mixing chamber 10 Air inlet 11; the upper end surface of the cooling tower body 1 is provided with an air cylinder 2 communicated with the air mixing chamber 10, and the air outlet of the air cylinder 2 is installed with a fan for driving the air circulation in the air mixing chamber 10 fan;

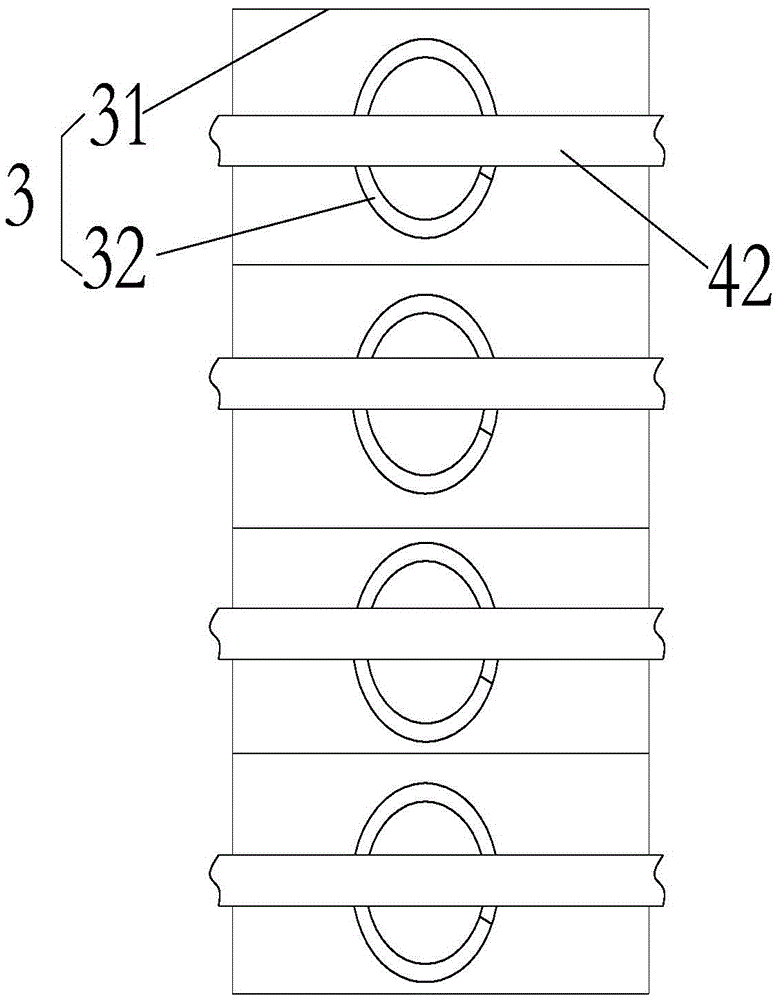

[0025] Two sets of water cooling coil assemblies 3 are arranged on one side of the air inlet 11 of the cooling tower body, and the water cooling coil assemblies 3 include six mutually independent coil installation passages 31, and each coil installation passage 31 has A water cooling coil 32 that can circulate heat medium is installed; one end of the coil installation channel 31 is provided with a first air inle...

Embodiment 2

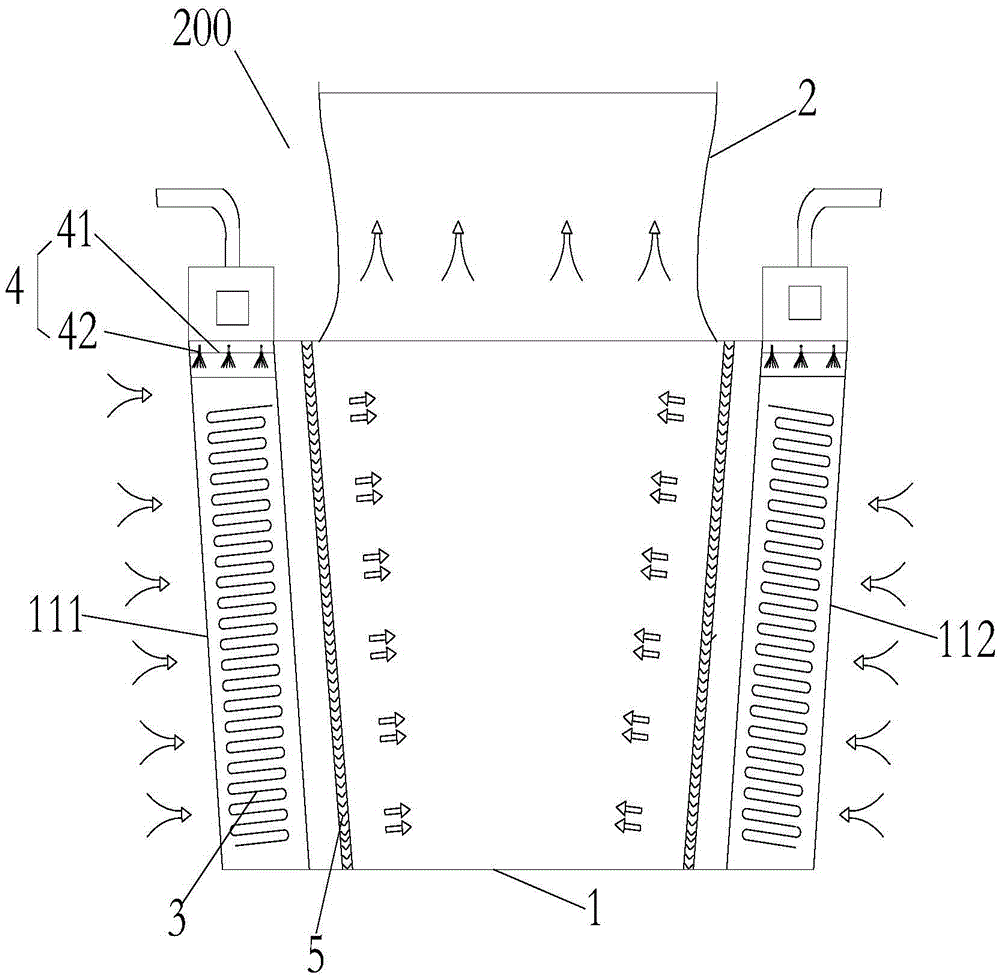

[0031] refer to Figure 2-3 , a sub-unit water-saving and fog-eliminating closed cooling tower described in this embodiment includes a cooling tower body 1 having an air mixing chamber 10, and the cooling tower body 1 is provided with a cooling tower body communicating with the air mixing chamber 10 Air inlet 11; the upper end surface of the cooling tower body 1 is provided with an air cylinder 2 communicated with the air mixing chamber 10, and the air outlet of the air cylinder 2 is installed with a fan for driving the air circulation in the air mixing chamber 10 fan;

[0032] Two sets of water cooling coil assemblies 3 are arranged on one side of the air inlet 11 of the cooling tower body, and the water cooling coil assemblies 3 include four mutually independent coil installation channels 31, each coil installation channel 31 has A water cooling coil 32 that can circulate heat medium is installed; one end of the coil installation channel 31 is provided with a first air inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com