High-performance nano magnesium-based hydrogen storage material and preparation method thereof

A hydrogen storage material and nano-magnesium technology, which is applied in the fields of nanotechnology, nanotechnology, and nanotechnology for materials and surface science, can solve the problems of unsatisfactory hydrogen absorption and desorption kinetic performance and high hydrogen desorption temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l95

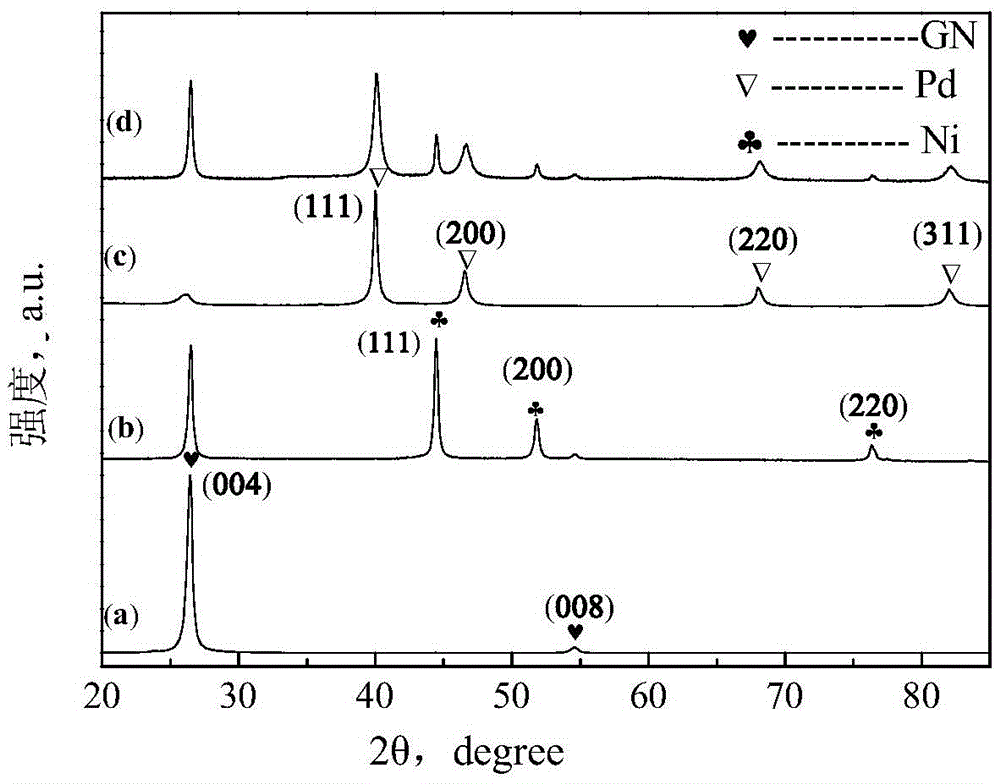

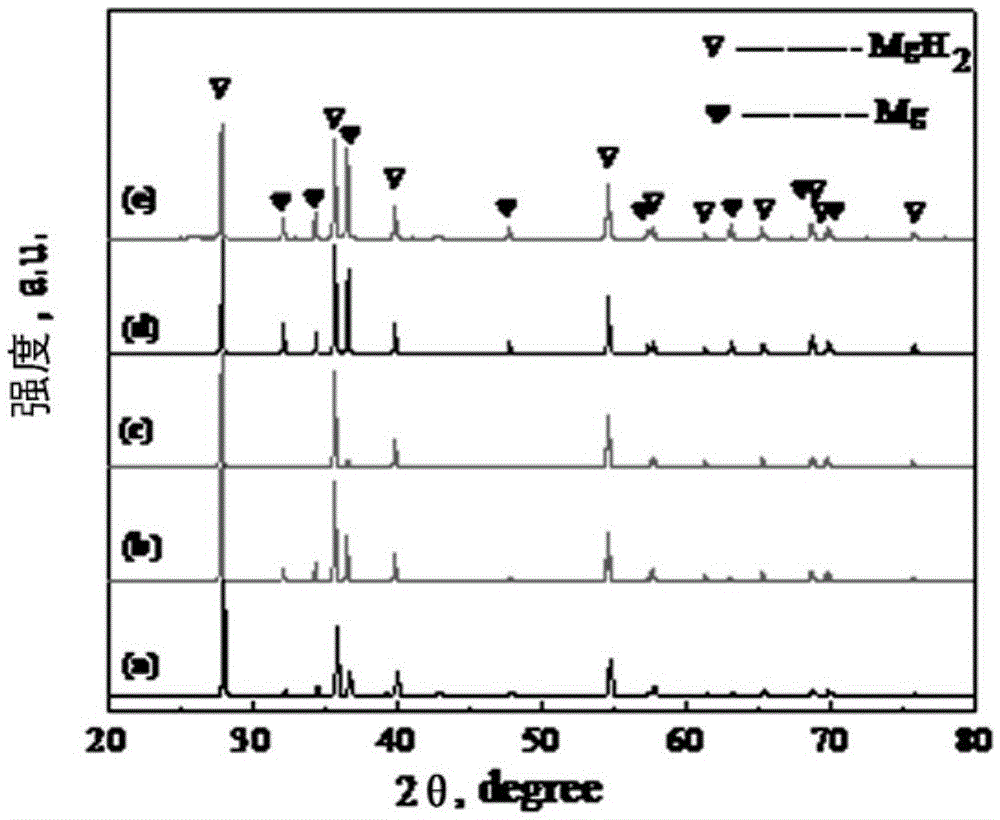

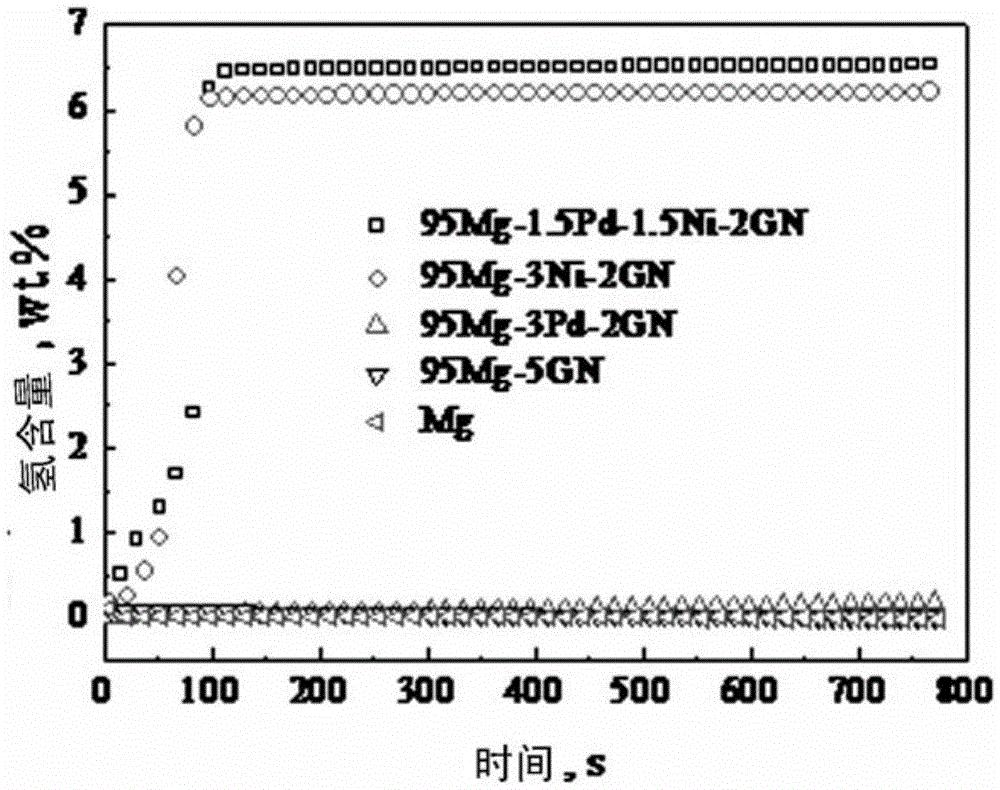

[0057] Preparation of Example 195Mg-1.5Pd-1.5Ni-2GN Nano Magnesium-based Hydrogen Storage Material

[0058] (1) Preparation of graphene-supported nickel and palladium powders:

[0059] (a) Putting graphene nanosheets into concentrated HNO 3 In the solution, reflux at 140°C for 8 hours, cool to room temperature, wash with deionized water to neutrality and dry to obtain functionalized graphene powder;

[0060] (b) 0.4g functionalized graphene powder and 1.4865g Ni(NO 3 ) 2 ·6H 2 O (the mass ratio of nickel to graphene is 3:4) was added to 30mL of acetone reagent, mixed ultrasonically and then dried; the dried powder was calcined in an argon atmosphere at 400°C for 4h, and then heated at 450°C Reduction in a hydrogen atmosphere for 4 hours, and finally cooled naturally to room temperature to obtain graphene-supported nano-nickel particle powder;

[0061](c) Mix 0.7g of graphene-loaded nano-nickel particle powder with ethylene glycol reagent, and ultrasonically mix for 1h to ...

Embodiment 295

[0093] Embodiment 295Mg-1.4Pd-1.4Ni-2.2GN

[0094] (1) Preparation of graphene-supported nickel and palladium powders:

[0095] (a) Putting graphene nanosheets into concentrated HNO 3 In the solution, reflux at 140°C for 8 hours, cool to room temperature, wash with deionized water to neutrality and dry to obtain functionalized graphene powder;

[0096] (b) Add 0.6g of functionalized graphene powder and 1.97g of Ni(NO3)2·6H2O (the mass ratio of nickel to graphene is 2:3) into 30mL of acetone reagent, and dry it after ultrasonic mixing; The final powder was calcined in an argon atmosphere at 400°C for 4h, then reduced in a hydrogen atmosphere at 450°C for 4h, and finally cooled naturally to room temperature to obtain a graphene-loaded nickel nanoparticle powder;

[0097] (c) 1.0g graphene-loaded nano-nickel particle powder is mixed with 30mL ethylene glycol reagent, and ultrasonic 1h mixes homogeneously to make mixed solution; 0.668gPdCl Powder (nickel and palladium content ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com