Pulverized coal fluidizing and injection device for blast furnace

A blowing device, pulverized coal technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems affecting pulverized coal transportation, uneven air distribution, etc., to improve the fluidization effect, ensure uniformity and stability, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

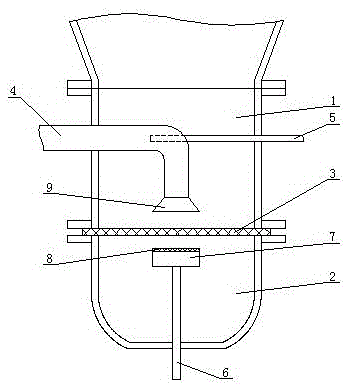

[0027] Such as figure 1 As shown, the present invention includes an injection chamber 1 and a fluidization chamber 2 , the fluidization chamber 2 is arranged below the injection chamber 1 , and the fluidization chamber 2 communicates with the injection chamber 1 through a fluidization plate 3 . The pulverized coal conveying pipe 4 enters the spray chamber 1 from one side of the spray chamber 1 and then bends vertically downward, and the inlet end 9 of the pulverized coal conveying pipe is trumpet-shaped. The pulverized coal air supply pipe 5 enters the pulverized coal conveying pipe 4 after entering the pulverized coal injection chamber 1 from the other side of the pulverized coal injection chamber. The fluidization gas inlet pipe 6 extends into the fluidization chamber 2 , and the outlet end of the fluidization gas inlet pipe 6 is provided with a fluidization gas distribution device, which is located in the central area of the fluidization chamber 2 . One end of the fluidi...

Embodiment 2

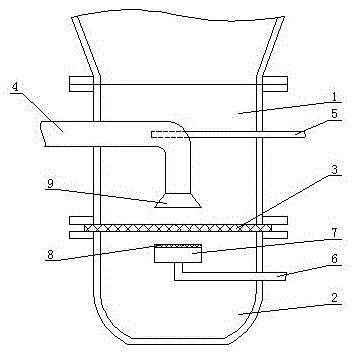

[0035] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that one end of the fluidizing gas inlet pipe 6 communicates with the bottom of the fluidizing gas distribution device, and the other end of the fluidizing gas inlet pipe 6 is bent from the fluidization chamber 2 side protrudes. This structural design is beneficial to save the space in the lower part of the fluidization chamber, and avoids the unfavorable construction and maintenance caused by not reserving the lower space during installation.

Embodiment 3

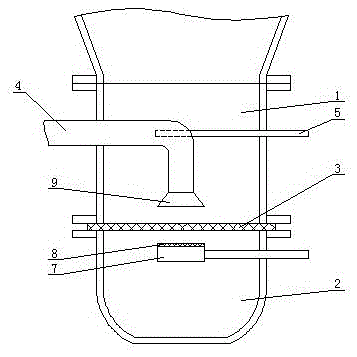

[0037] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that one end of the fluidizing gas inlet pipe 6 communicates with one side of the fluidizing gas distribution device, and the other end of the fluidizing gas inlet pipe 6 connects with one side of the fluidizing chamber 2 side out. This structural design is beneficial to save the space in the lower part of the fluidization chamber, and avoids the unfavorable construction and maintenance caused by not reserving the lower space during installation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com