Liquid crystal composition and liquid-crystal display device

A liquid crystal composition and compound technology, which is applied in the direction of liquid crystal materials, instruments, chemical instruments and methods, etc., can solve the problems that liquid crystal displays cannot work in high temperature environments, liquid crystal displays cannot display normally, and the reliability performance of high and low temperatures is reduced. Achieve proper dielectric anisotropy, good UV stability, and lower driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

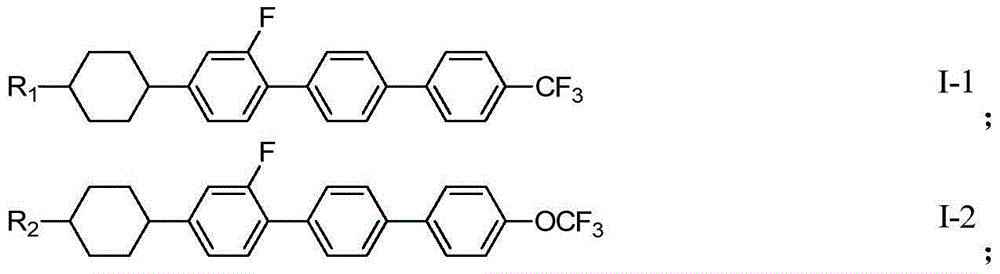

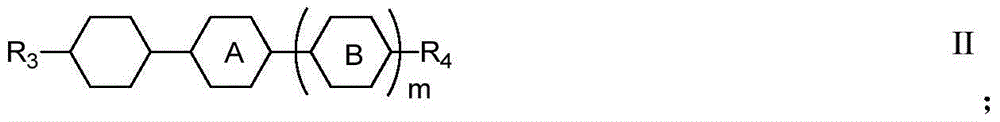

[0183] The compound of general formula Ⅰ-2 is obtained by the method of suzuki coupling using commercially available raw materials, and the synthetic route is as follows:

[0184]

[0185] Among them, R 2 represents an alkyl group having 1 to 5 carbon atoms. Both Compound A and Compound B are commercially available.

[0186] Prepare the compound of following structural formula by above-mentioned method:

[0187] When R 2 =C 2 h 5 When, obtain the compound of following structural formula by above-mentioned method:

[0188]

[0189] When R 2 =C 3 h 7 When, obtain the compound of following structural formula by above-mentioned method:

[0190]

[0191] When R 2 =C 4 h 9 When, obtain the compound of following structural formula by above-mentioned method:

[0192]

[0193] When R 2 =C 5 h 11 When, obtain the compound of following structural formula by above-mentioned method:

[0194]

[0195] Table 2 Compound Liquid Crystal Performance Parameters

...

Embodiment 1

[0205] The liquid crystal composition of Example 1 was formulated according to the compounds and weight percentages listed in Table 4, and it was filled between the two substrates of the liquid crystal display for performance testing. The test data are shown in the following table:

[0206] Table 4 liquid crystal composition formula and test performance thereof

[0207]

[0208] From the above Example 1 and Comparative Example 1, it can be seen that when the optical anisotropy, dielectric anisotropy, and clearing point are similar, the liquid crystal composition of the present invention has better low-temperature storage stability, and at the same time, it is stable under high temperature and UV light. It has a better voltage retention rate after exposure to light, and is more suitable for harsh environments.

Embodiment 2

[0214] The liquid crystal composition of Example 2 was prepared by each compound listed in Table 6 and the weight percentage, which was filled between the two substrates of the liquid crystal display for performance testing. The test data are shown in the following table:

[0215] Table 6 liquid crystal composition formula and test performance thereof

[0216]

[0217] From the above Example 2 and Comparative Example 2, it can be seen that when the optical anisotropy, dielectric anisotropy and clearing point are similar, the liquid crystal composition of the present invention has better low-temperature storage stability, and at the same time, it has better storage stability at high temperature and UV After lighting, it has a better voltage retention rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com