Industrial production method for diammonium phosphate coloring by means of humic acid

A humic acid diammonium phosphate and diammonium phosphate technology, applied in the field of phosphate compound fertilizer, can solve the problems of pollution, accumulation, and unrealistic coloration, and achieve obvious economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

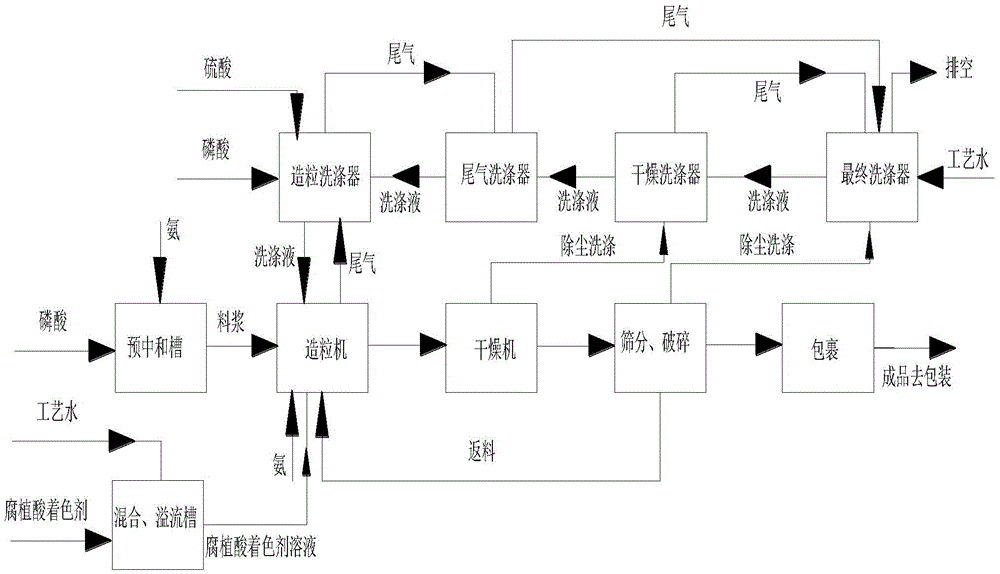

Method used

Image

Examples

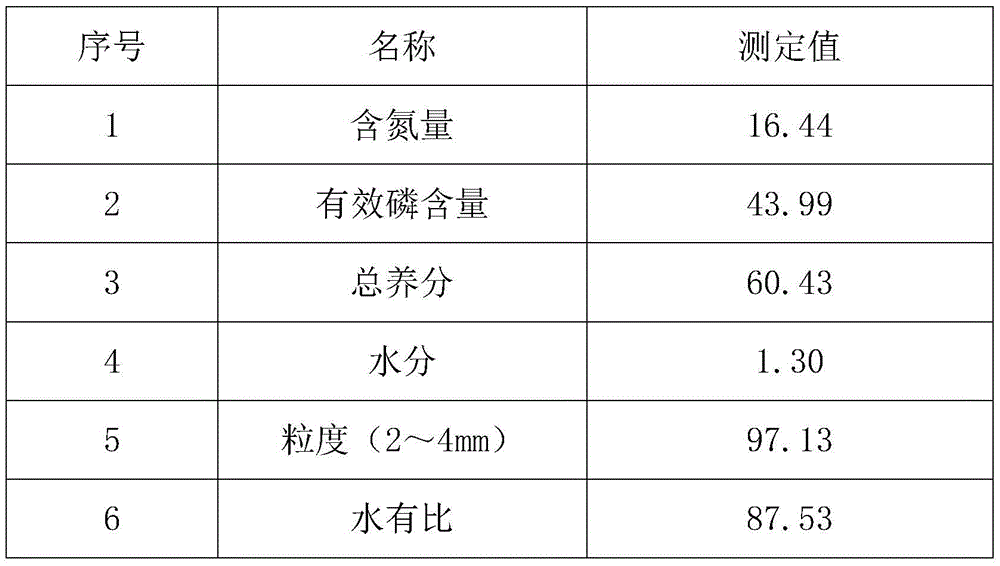

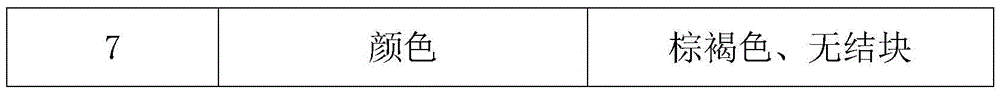

Embodiment 1

[0036] (1) Add HA 总 =62.42%, H 水 The ammonium humate colorant raw material of =45.85% is mixed with process water according to the consumption of 2.5kg (in terms of per ton of diammonium phosphate product) in the melting tank, and is mixed with a concentration of 10% colorant solution, and the prepared solution Stir evenly and overflow to the solution tank for later use;

[0037] (2) will P 2 o 5 Concentration 44.75%, specific gravity 1.65×10 3 kg / m 3 , with a solid content of 12.20% and SO4 2- Phosphoric acid with a content of 4.20% is metered and enters the granulation washer to wash the tail gas produced by granulation and adjust the specific gravity of the washing liquid to 1.58×10 3 kg / m 3 , pass into the tubular reactor to neutralize with phosphoric acid, sulfuric acid, liquid ammonia, after the reaction generates a slurry with a neutralization degree of 1.77, mix it with the colorant solution injected in step (1) and spray it on the granulation machine bed, And ...

Embodiment 2

[0043] (1) Add HA 总 =72.47%, H 水 =61.59% potassium humate coloring agent raw material is mixed with process water in melting tank according to the consumption of 1.0kg (in terms of per ton of diammonium phosphate product), and is prepared into a coloring agent solution with a concentration of 8%, and the prepared solution is stirred After uniformity, overflow to the solution tank for standby;

[0044] (2) will P 2 o 5 Concentration 45.51%, specific gravity 1.66×10 3 kg / m 3 , with a solid content of 13.10% and SO4 2- Phosphoric acid with a content of 4.15% is metered and enters the granulation washer to wash the tail gas produced by granulation and adjust the specific gravity of the washing liquid to 1.57×10 3 kg / m 3 , feed into the tubular reactor to neutralize with phosphoric acid, sulfuric acid, liquid ammonia, after the reaction generates a slurry with a neutralization degree of 1.80, mix it with the colorant solution injected in step (1) and spray it on the granulat...

Embodiment 3

[0050] (1) Add HA 总 =72.49%, H 水 =52.07% potassium fulvic acid coloring agent raw material is mixed with process water according to the consumption of 1.5kg (in terms of per ton of diammonium phosphate product) in the melting tank, and is prepared into a coloring agent solution with a concentration of 12%. Stir evenly and overflow to the solution tank for later use;

[0051] (2) will P 2 o 5 Concentration 45.26%, specific gravity 1.65×10 3 kg / m 3 , with a solid content of 12.9% and SO4 2- Phosphoric acid with a content of 4.08% is metered and enters the granulation washer to wash the tail gas produced by granulation and adjust the specific gravity of the washing liquid to 1.59×10 3 kg / m 3 , pass into the tubular reactor to neutralize with phosphoric acid, sulfuric acid, liquid ammonia, after the reaction generates a slurry with a neutralization degree of 1.82, mix it with the colorant solution that is injected in step (1) and spray it on the granulation machine bed, Wr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com