Method and device for microwave non-destructive testing, rapid repair and real-time monitoring of composite materials

A composite material and non-destructive testing technology, applied in the direction of measuring devices, analyzing materials, and using microwave means for material analysis, etc., can solve problems such as uneven temperature field distribution and inability to control repair quality in real time, so as to improve repair speed and repair quality , light weight, good repair quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

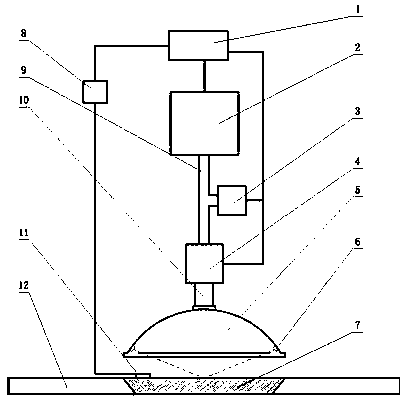

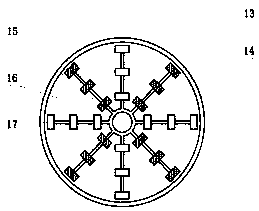

[0034] Such as Figure 1-2 shown.

[0035] A method for microwave non-destructive testing, rapid repair and real-time monitoring of composite materials. First, use the same microwave source and transceiver antenna to realize microwave non-destructive testing of damaged areas of composite materials; secondly, start microwave heating to cure the area to be repaired according to the test results; third Monitor the curing state of the composite material while curing and repairing, and adjust the repairing process in real time; wherein, detection, monitoring and repairing can be performed simultaneously, step by step or separately. The frequency of microwave detection, repair and monitoring is between 300MHz and 300GHz, preferably between 2GHz and 8GHz. Such as figure 1 As shown, the microwave source generates microwave under the control of the microwave controller and passes through the transmission line, and the microwave is radiated by the hemispherical transceiver to directly...

Embodiment 2

[0045] Such as Figure 1-2 shown.

[0046] An integrated device for microwave non-destructive testing, rapid repair and real-time monitoring of composite materials, which includes a microwave controller 1, a microwave source 2, a microwave switcher 3, an active amplifier 4, a hemispherical transceiver 5, a microwave transceiver antenna 6, a signal Modulator 8 (using fiber optic signal modulator) and temperature sensor 11 (using fiber grating temperature sensor), such as figure 1 As shown, the microwave controller 1 controls the microwave source 2 to generate microwaves and transmits them to the microwave transceiver antenna 6 in the hemispherical transceiver 5 through the transmission line 9 to radiate microwaves to directly detect the components of the composite material 12 that need to be inspected and repaired, or through the microwave switcher 3 Switch to the active amplifier 4 to amplify, and quickly repair the composite material heating and curing area 7 through the mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com