Electrolytic and mechanical combined machining servo control method and system based on short circuit rate

A servo control system and composite processing technology, applied in electric processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low processing efficiency, scratches or wear on the surface of the workpiece, and improve the surface quality of the workpiece. Improve machining stability and machining accuracy, and reduce the amount of computation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

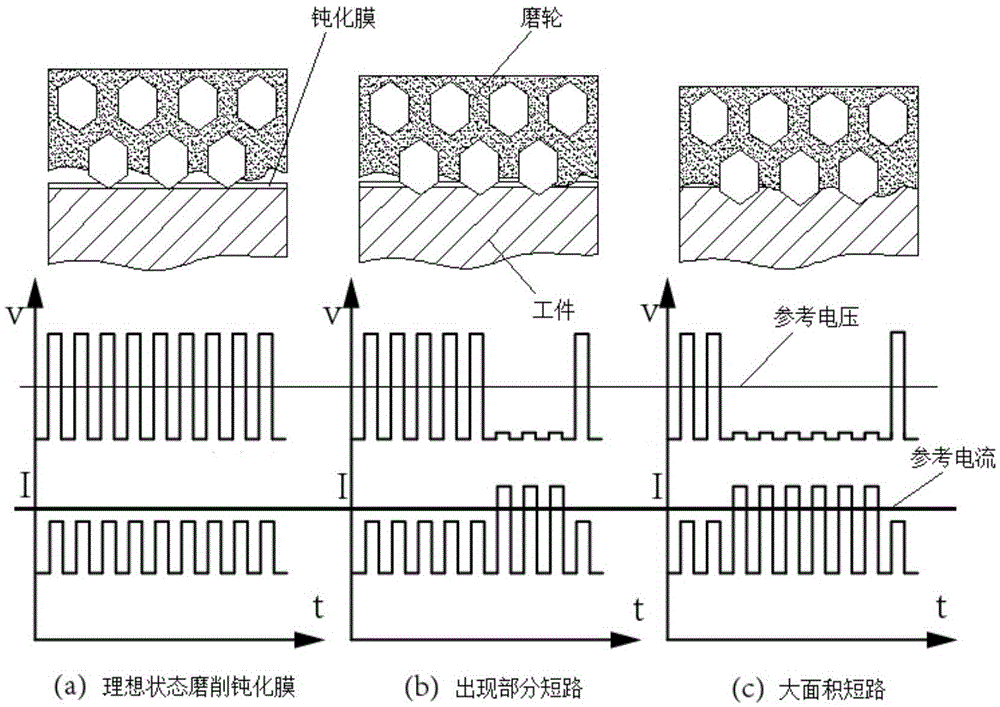

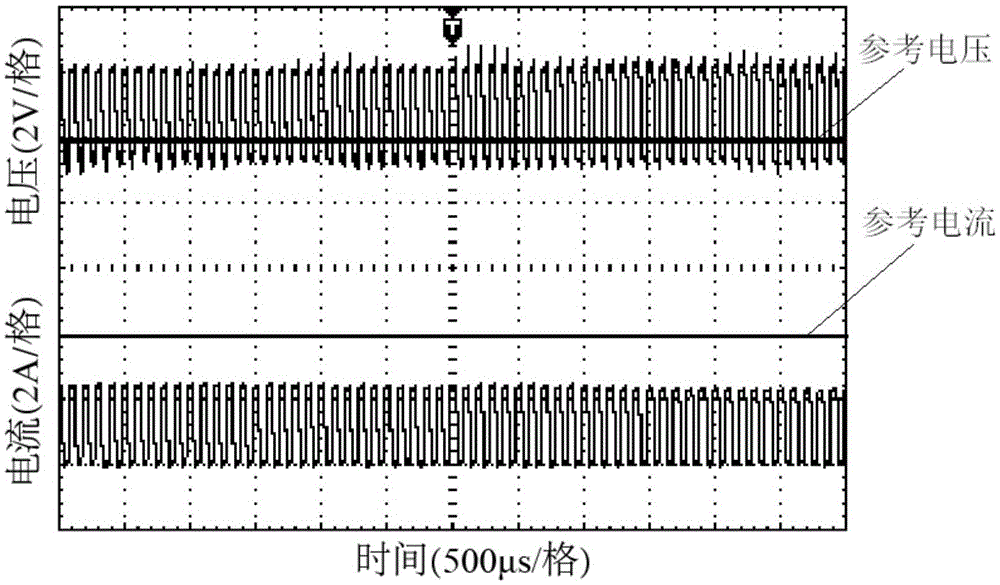

[0025] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the servo control system of electrolytic mechanical compound machining based on the short circuit rate of this embodiment includes a current sampling circuit, a voltage sampling circuit, a comparison circuit, a counter, or an arithmetic unit and a CPU, a current sampling circuit and a voltage sampling circuit. The current signal and voltage signal collected by the sampling circuit are respectively compared and screened by the comparison circuit and converted into a current standard pulse signal and a voltage standard pulse signal. The current standard pulse signal passes through the counter to obtain the count value A per unit time. And the voltage standard pulse signal is sent to the counter to obtain the count value B through the OR arithmetic unit, and the count value A and the count value B enter the CPU for division to obtain the A / B value, which is the instantaneous short circuit rate of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com