Pneumatic punching mechanism

A kind of pneumatic punching and cylinder technology, which is used in perforating tools, metal processing equipment, manufacturing tools, etc., can solve the problems of easy out-of-tolerance, inability to achieve batch production, uneven hole quality, etc. The effect of tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below, and its working principle will be set forth.

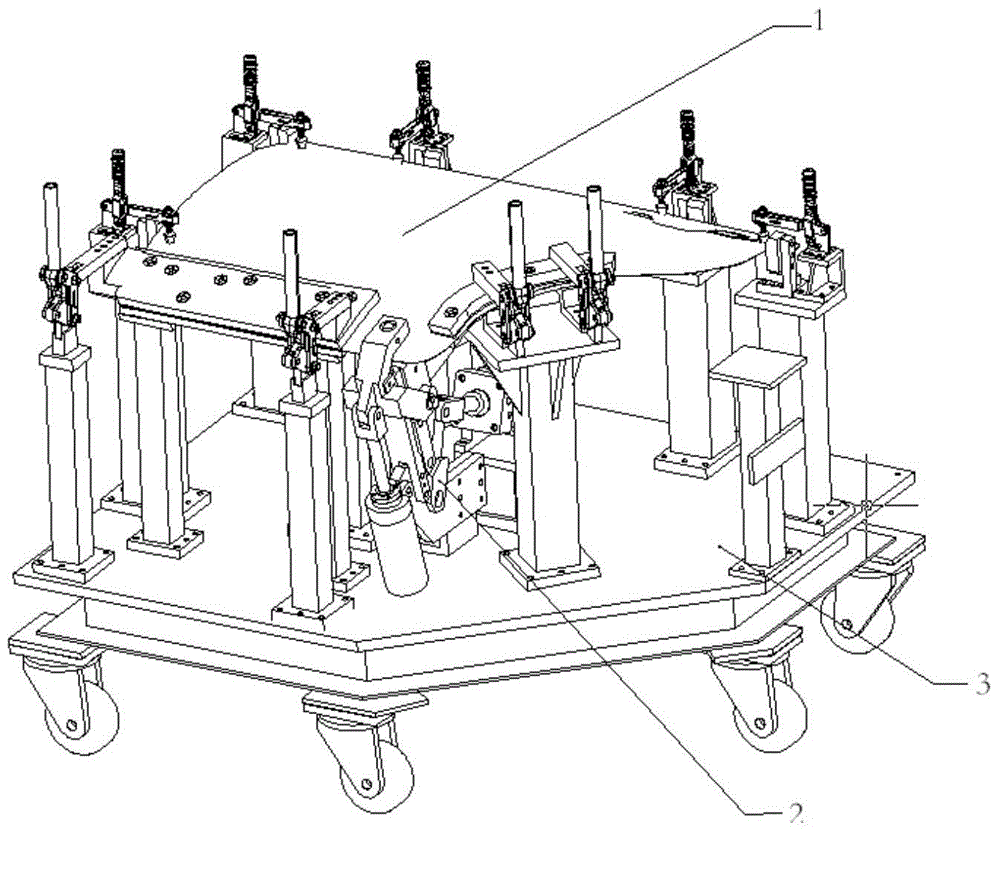

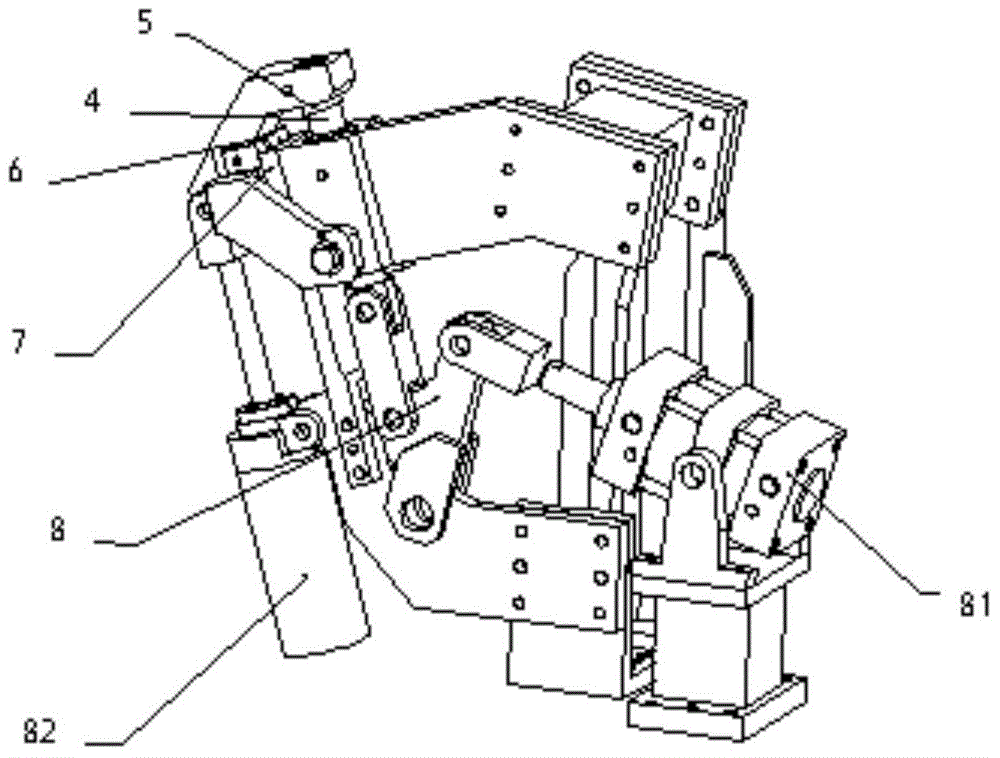

[0018] figure 2 The punching mechanism shown is a detailed diagram of the present invention, which is combined with other functional components to form a figure 1 Drilling jig shown; place the sheet metal parts to be reprocessed on the pneumatic punching mechanism of the drilling jig, use positioning pins and pressing devices to accurately position the sheet metal parts, clamp them firmly and manually press them with a compactor sheet metal parts;

[0019] Ventilate the CK1B63 cylinder 82, the cylinder starts to work, and drives the die 5 to move. When the limit block 6 and the limit block 7 are completely fitted, the die 5 is positioned accurately, the driving force of the cylinder is converted into a pressing force, and the die 5 is pressed. Tighten the profile of the part and play the role of the blank holder;

[0020] When the die 5 is accurately posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com