Adjusting connecting seat tool clamp with screw rod

A technology of connecting seat and wire, which is applied in the field of tooling and fixtures, can solve the problems of workpiece accuracy error, increased part cost, slow processing speed, etc., and achieve the effects of ensuring position tolerance, improving production efficiency, and fast clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

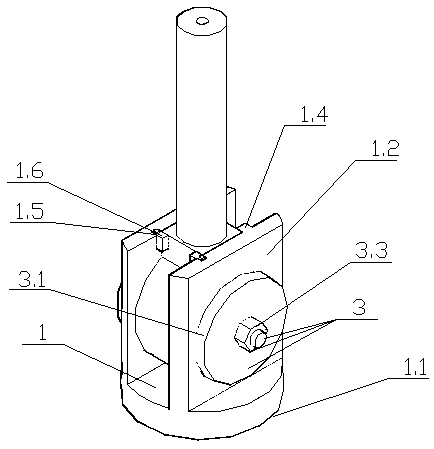

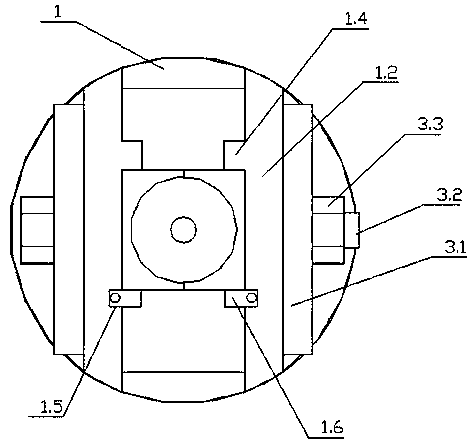

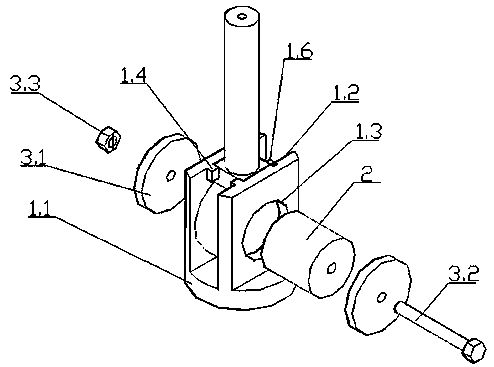

[0012] Now in conjunction with accompanying drawing, the present invention is further elaborated.

[0013] Such as Figure 1-4 As shown, a tooling fixture with an adjustable connection seat with a screw rod includes a clamping body 1, a fixed shaft 2 and a clamping mechanism 3. The clamping body 1 includes a clamping disc 1.1 and a clamping plate 1.2. Two clamping plates 1.2 are respectively fixed on the left and right sides of the top surface by welding and the two clamping plates 1.2 are parallel to each other, and there are relative installation holes 1.3 on the two clamping plates 1.2; A fixed shaft 2 is inserted inside, and a clamping mechanism 3 is provided at the left and right ends of the fixed shaft 2. The clamping mechanism 3 includes a clamping disc 3.1, a clamping bolt 3.2 and a clamping nut 3.3. The clamping disc 3.1 is Two and two clamping discs 3.1 are distributed at the left and right ends of the fixed shaft 2, the diameter of the clamping discs 3.1 is larger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com