Step-type multistation once-forming cutter

A forming knife and multi-station technology, which is applied in the direction of manufacturing tools, tool holder accessories, metal processing equipment, etc., can solve the problems of time-consuming, low efficiency, and long processing time, so as to eliminate large dispersion and reduce The effect of reducing cost and processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The following is a detailed description of the technical solutions of the present invention through the accompanying drawings.

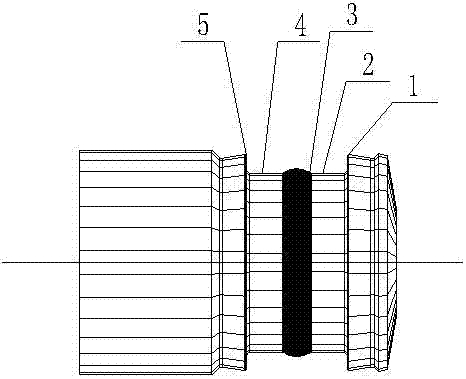

[0010] Such as figure 1 As shown, a stepped multi-station one-time forming knife according to the present invention is provided with a dust-proof groove blade one 1, an inner diameter blade one 2, a channel blade 3, an inner diameter blade two 4, and a dust-proof groove blade on the forming knife. Groove blade two 5.

[0011] Further, the widths of the inner diameter blade 1 and the inner diameter blade 2 are the same.

[0012] The blank is directly placed on the forming knife, and the forming knife processes the dust-proof grooves on both sides of the outer ring of the bearing, the groove of the outer ring, and the inner diameter of the outer ring at one time, which reduces the cost of the tool and shortens the processing time by 4 times. The processing efficiency is greatly improved. At the same time, the forming knife processing can bette...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com