Device and method for coating inner wall of oil casing coupling with anti-friction nano coating

A kind of oil casing pipe and nanotechnology, which is applied to the device and coating of the surface coating liquid, which can solve the problems of natural environment damage, waste liquid discharge, and increase of production cost, so as to ensure the thickness of the coating layer and reduce the production cost. Cost, the effect of improving the reliability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

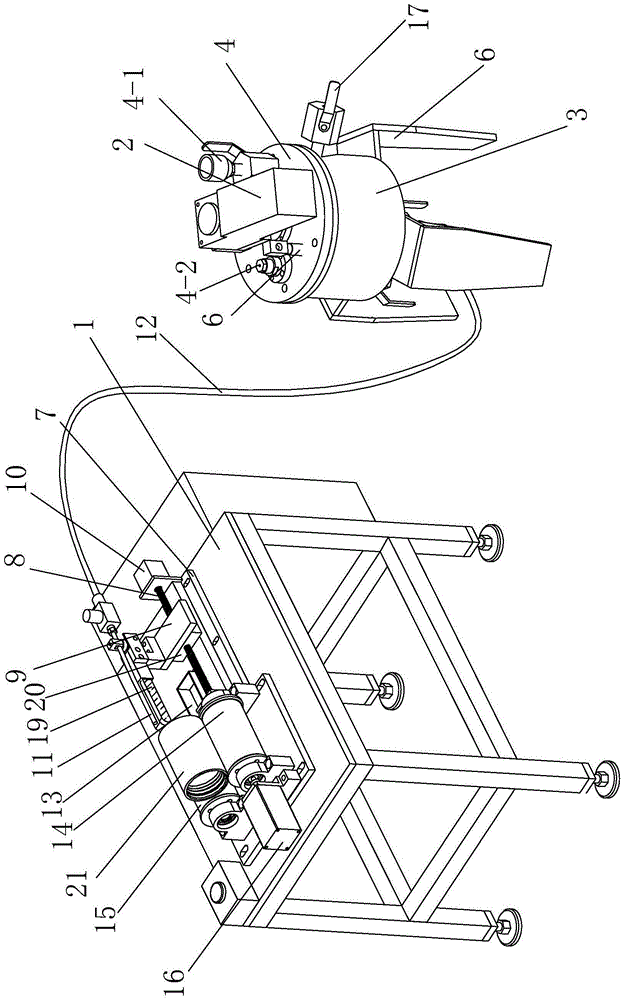

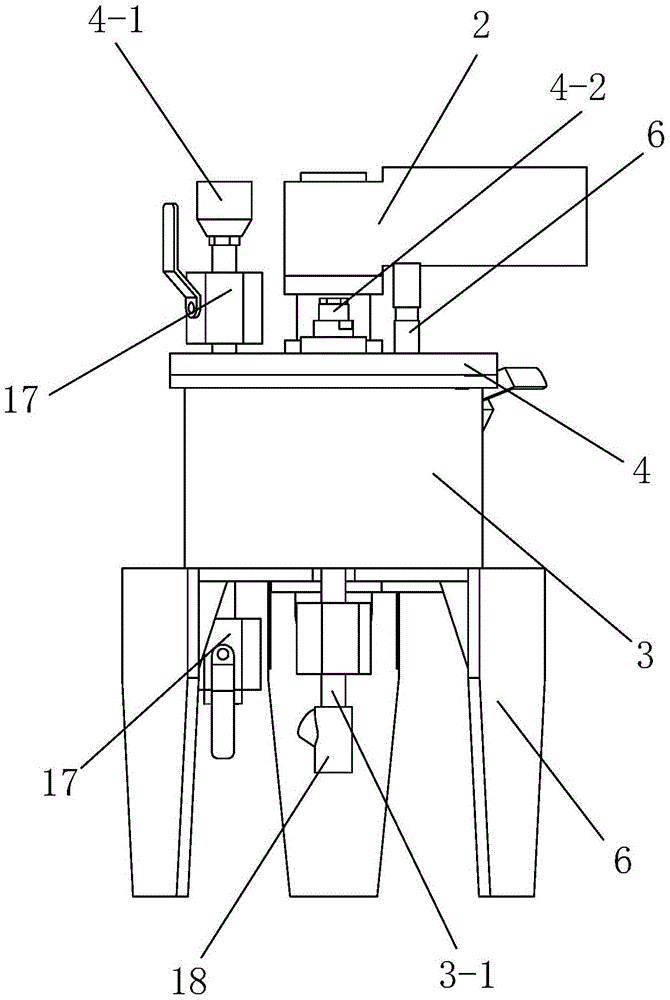

[0046] Such as 1, figure 2 and image 3As shown, the equipment for coating the inner wall of oil casing collars with nano-friction-reducing coatings in this embodiment includes a storage mechanism for containing nano-friction-reducing coatings, a feeding mechanism for feeding the contained nano-friction-reducing coatings, and The workpiece rotation mechanism for rotating the workpiece 21 of the oil casing collar, the feeding mechanism and the workpiece rotation mechanism are both installed on the workbench 1, the feeding mechanism is connected with the storage mechanism, and the storage mechanism includes Nano anti-friction coating and its stirring tank and the first driving motor 2 installed on the stirring tank and used to drive the stirring, the feeding mechanism includes a base 7 and a second driving motor arranged on the base 7 10. The power output end of the second drive motor 10 is connected to the lead screw 8, the lead screw 8 is threaded to the lead screw nut 20, t...

Embodiment 2

[0057] combine figure 1 , figure 2 and image 3 In this embodiment, the method for coating the inner wall of the oil casing collar with the nano-friction-reducing coating using the equipment described in Example 1 includes the following steps:

[0058] Step 1. Place the oil casing coupling workpiece to be coated on the top of the driving roller 14 and the driven roller 15, and then use the third drive motor 16 to drive the driving roller 14 and the driven roller 15 to rotate, thereby driving the oil casing The coupling workpiece rotates around its own axis at a rotation rate of 16r / min;

[0059] Step 2, turn on the first drive motor 2, then add the nano-friction-reducing coating into the stirring tank and stir evenly;

[0060] In the specific implementation process, the nano-friction-reducing coating in the stirring tank can be stirred under the condition of a hot water bath, so that its viscosity is lower than room temperature, its fluidity is good, and it is easier to co...

Embodiment 3

[0065] combine figure 1 , figure 2 and image 3 In this embodiment, the method for coating the inner wall of the oil casing collar with the nano-friction-reducing coating using the equipment described in Example 1 includes the following steps:

[0066] Step 1. Place the oil casing coupling workpiece to be coated on the top of the driving roller 14 and the driven roller 15, and then use the third drive motor 16 to drive the driving roller 14 and the driven roller 15 to rotate, thereby driving the oil casing The coupling workpiece rotates around its own axis at a rotation rate of 16r / min;

[0067] Step 2, turn on the first drive motor 2, then add the nano-friction-reducing coating into the stirring tank and stir evenly;

[0068] In the specific implementation process, the nano-friction-reducing coating in the stirring tank can be stirred under the condition of a hot water bath, so that its viscosity is lower than room temperature, its fluidity is good, and it is easier to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com