A fixed-bed hydrogenation reactor and its application method

A hydrogenation reactor and reactor technology, applied in the field of petrochemical industry, can solve the problems of uneven distribution of hydrogen concentration in the catalyst bed, inability of reaction materials to pass through uniformly, and reduction of catalyst hydrogenation efficiency, so as to improve the hydrogenation reaction environment, Improve the gas-liquid distribution state and save equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

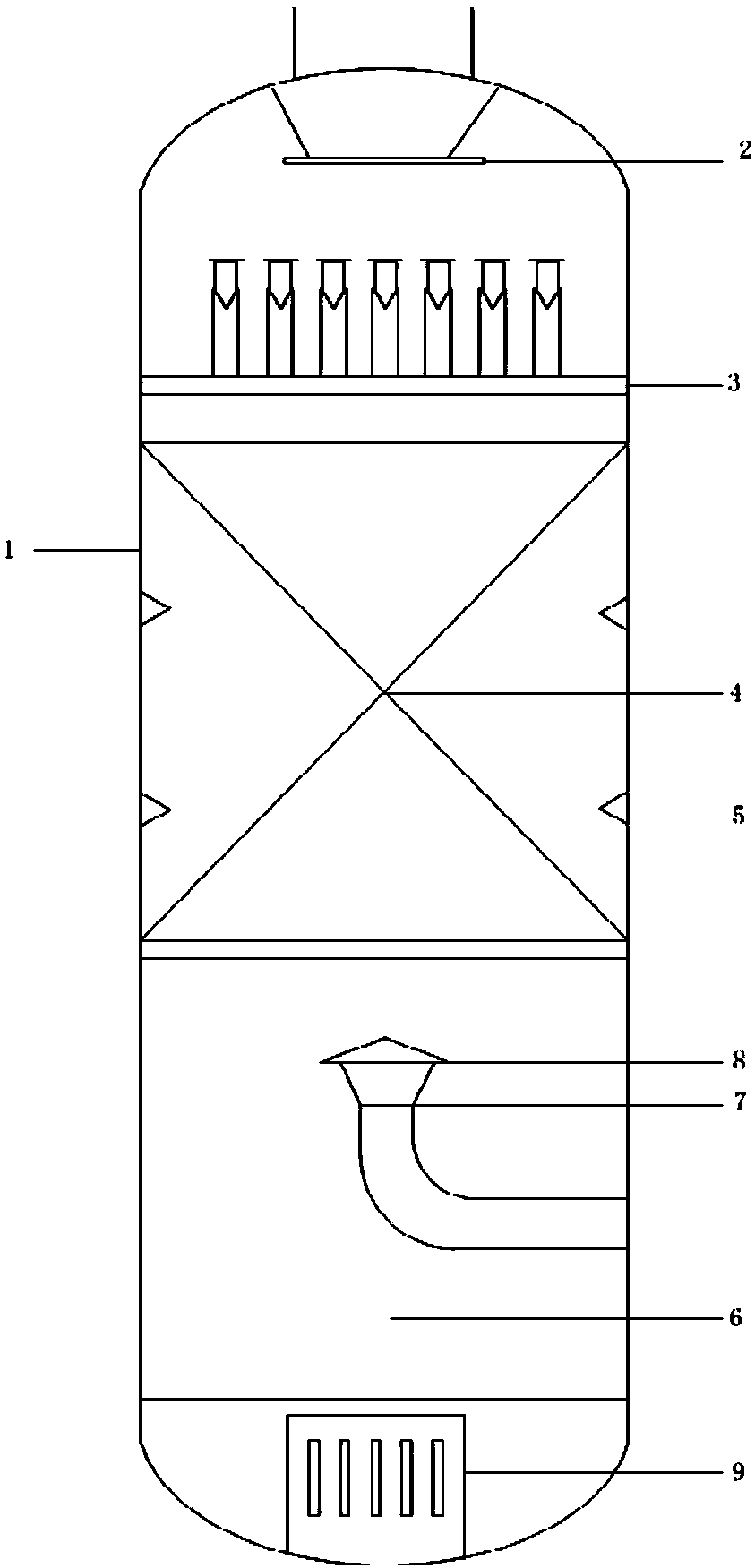

[0027] The fixed bed reactor is sequentially provided with a pre-distributor 2, a gas-liquid distribution plate 3, a catalyst bed 4, a gas-liquid phase separation chamber 6, and a liquid phase separation chamber 6 arranged at the bottom of the cylinder 1 from top to bottom along the axis of the cylinder 1. Phase outlet collector 9;

[0028] The top of the gas-liquid phase separation chamber 6 is provided with a gas phase discharge port 7, and its inner diameter is 16 centimeters. The upward direction of the feed port 7 is provided with a baffle plate 8, which is located directly above the gas phase discharge port 7 and is an upwardly directed cone with a horizontal cross-sectional diameter of 22 cm.

[0029] The height of the catalyst bed is 2.5 meters, and the inner diameter of the reactor cylinder is 1.25 meters. An annular baffle 5 is arranged on the inner wall of the cylinder 1 corresponding to the catalyst bed 4, and there is no gap between the inner wall of the cylinder ...

Embodiment 2

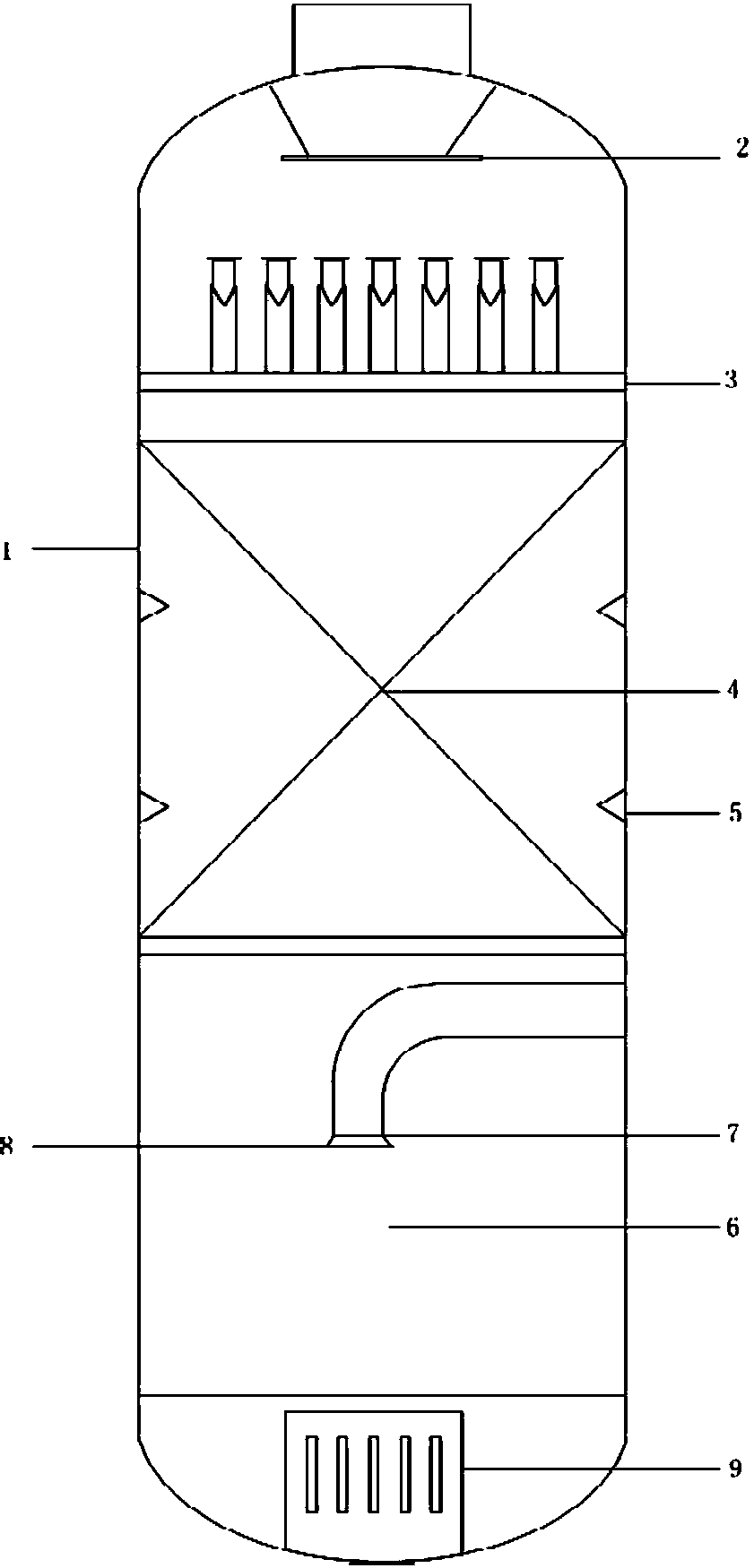

[0032] The top of the gas-liquid phase separation chamber 6 is provided with a gas phase discharge port 7, and its internal diameter is 16 centimeters. The gas phase discharge port 7 is a circular shape with an opening that is the center axis of the gas-liquid phase separation chamber 6 central axes. The downward direction of the discharge port 7 is provided with a baffle 8, which is located at the lower edge of the gas phase discharge port 7 and is in the shape of a flared barrel with a horizontal cross-sectional diameter of 20 cm.

[0033] Other reactor parameters, the reaction conditions of the liquid-phase selective hydrogenation of the C3 fraction to remove methylacetylene and propadiene are the same as in Example 1.

[0034] After the selective hydrogenation reaction, the MAPD content in the liquid phase discharge at the bottom of the reactor is 46ppm, the hydrogen content is 155ppm, and the MAPD and hydrogen content are 1567ppm in the gas phase recovery material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com