T-type oil-water separation equipment integrating two special wettable materials

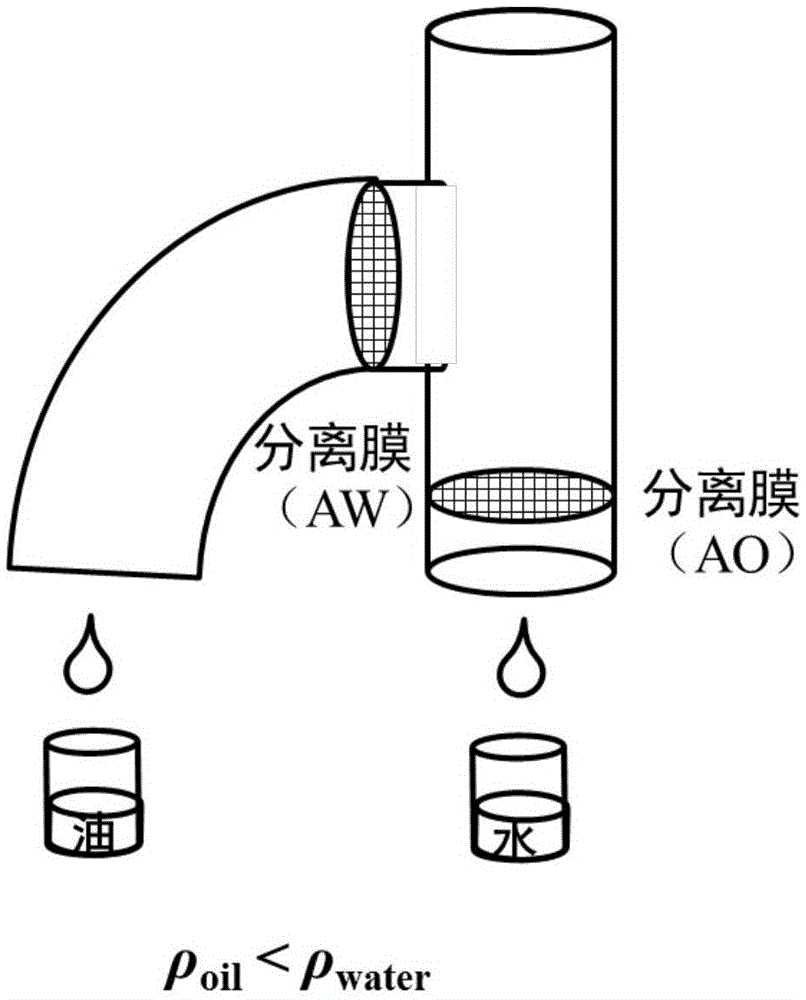

A technology of oil-water separation and wettability, which is applied in the field of T-type oil-water separation equipment and integrated oil-water separation device to meet the requirements of reducing mechanical strength, breaking through limitations, and reducing the effect of hydrostatic pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The commercial copper mesh was washed in acetone, ethanol, distilled water and HCl to remove dirt and oxides on the surface.

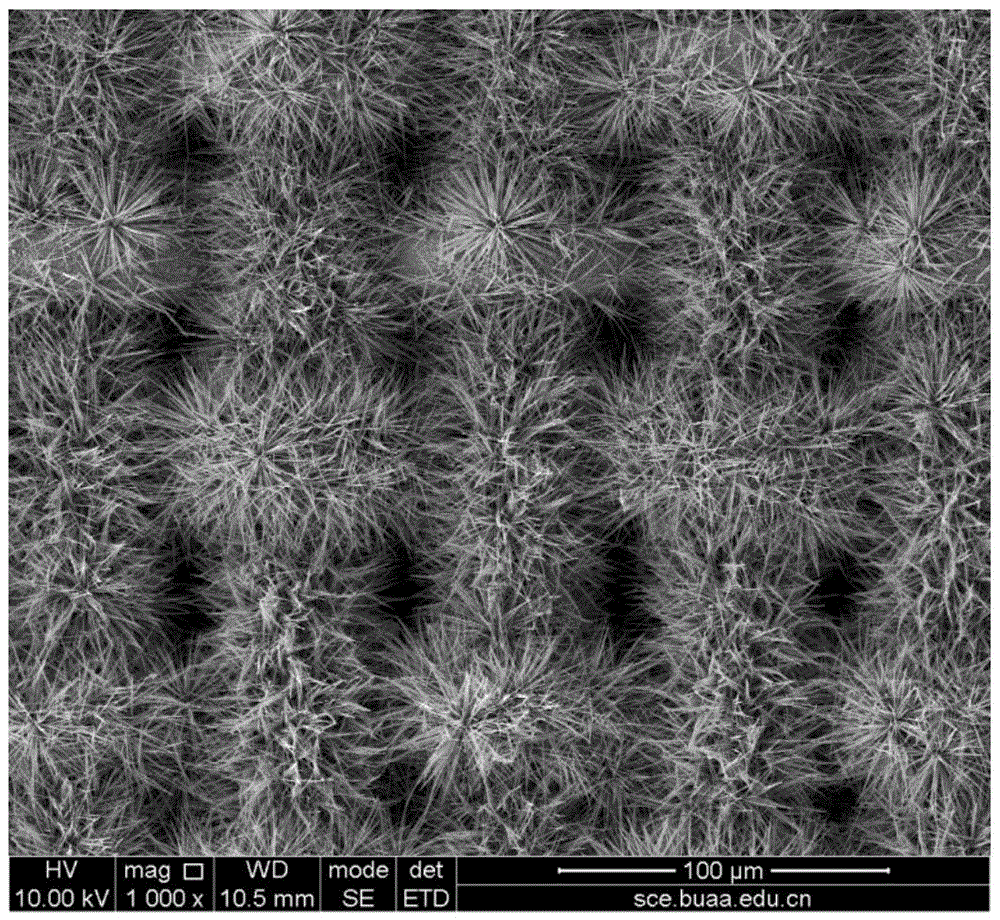

[0030] After drying, the cleaned copper mesh was immersed in a mixed aqueous solution of 0.5M sodium hydroxide and 0.1M potassium persulfate for 30 minutes to oxidize, and then washed with distilled water and dried to obtain a uniformly covering the surface of the copper mesh with the nano-needle structure ( figure 1 ). The oxidized copper mesh was modified in perfluorodecyltriethoxysilane at 180°C for 2h to obtain the separation membrane AW.

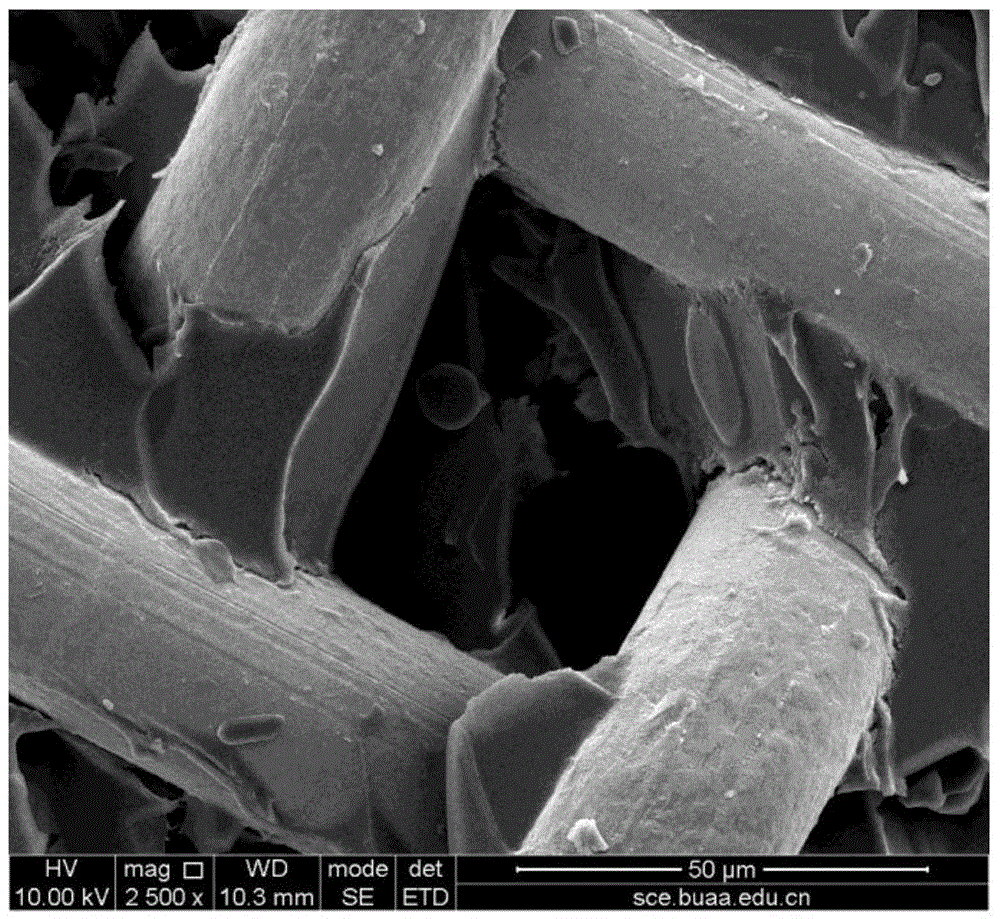

[0031] Prepare polyacrylamide hydrogel solution. The cleaned copper mesh is carefully immersed in a uniformly stirred solution to make the solution evenly adhere to the surface of the copper mesh, and then the copper mesh is pulled out horizontally and irradiated under ultraviolet light (365nm). After 5 minutes, the copper mesh was rinsed with distilled water to obtain a copper mesh coated with polyacrylamid...

Embodiment 2

[0036] The commercial stainless steel mesh was washed in acetone, ethanol, distilled water and HCl to remove the dirt on the surface.

[0037] After drying, the cleaned stainless steel mesh was immersed in a 0.1M copper chloride solution for 3 minutes, and dried with distilled water ultrasonically for 10 minutes. Then, it was modified in perfluorodecyltrimethoxysilane at 90°C for 10 hours to obtain the superhydrophobic and super lipophilic separation membrane AW.

[0038] Prepare polyacrylamide hydrogel solution. The cleaned stainless steel mesh is carefully immersed in a uniformly stirred solution to make the solution evenly adhere to the surface of the stainless steel mesh, and then the stainless steel mesh is pulled out horizontally and the sample is irradiated under ultraviolet light (365nm). After 5 minutes, the sample was washed with distilled water to obtain a stainless steel mesh coated with polyacrylamide hydrogel, that is, a superhydrophilic and underwater superoleophobi...

Embodiment 3

[0044] The commercial copper mesh was washed in acetone, ethanol, distilled water and HCl to remove the dirt on the surface. After drying, soak the cleaned copper mesh in a mixed aqueous solution of 3M sodium hydroxide and 2M potassium persulfate for 30 minutes, and rinse with distilled water for drying. It was dried with distilled water ultrasonically for 10 minutes to obtain a copper mesh with a nanoneedle structure uniformly covering the surface. Then, it was modified in perfluorodecyltrimethoxysilane at 150°C for 3h to obtain the separation membrane AW.

[0045] Prepare polydimethylaminoethyl methacrylate hydrogel solution. The cleaned copper mesh is carefully immersed in the evenly stirred solution to make the solution evenly adhere to the surface of the copper mesh, and then the copper mesh is pulled out horizontally and the sample is irradiated under ultraviolet light (365nm) for 120 minutes. The sample was rinsed with distilled water to obtain a copper mesh coated with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com