Assembly with friction arrangement

A technology of friction devices and components, applied in the direction of friction clutches, non-mechanical drive clutches, electric clutches, etc., can solve the problems of holding torque, not being able to hold positions, holding currents, etc., and achieve the effect of optimizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

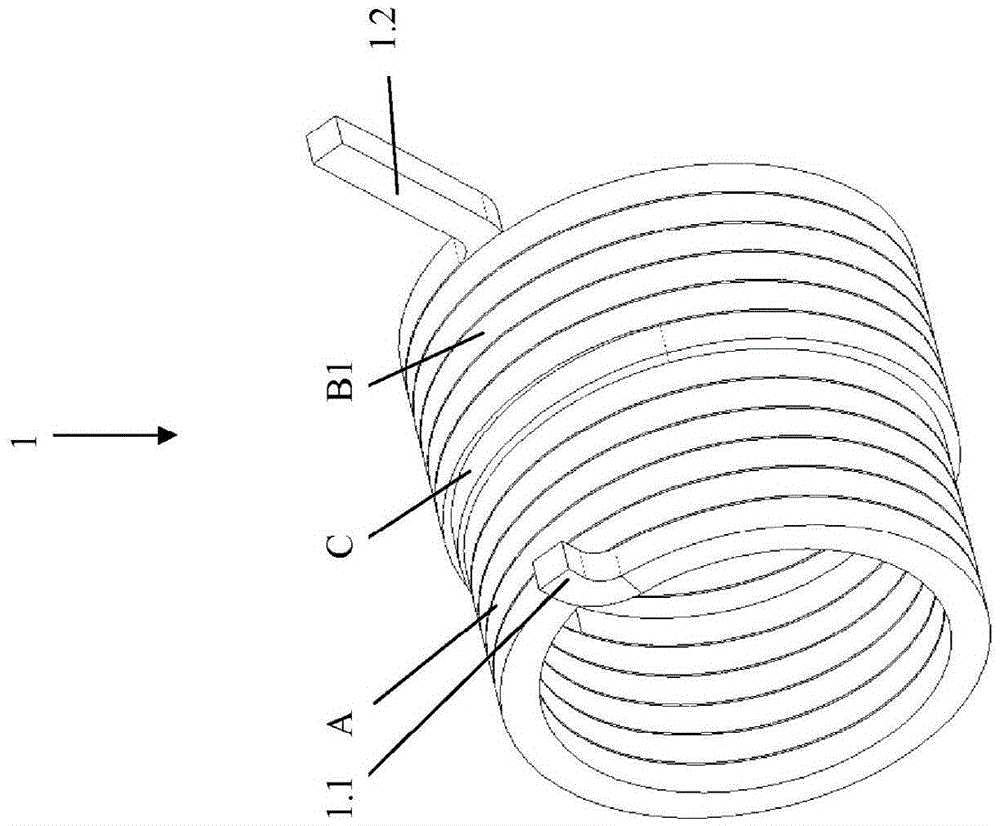

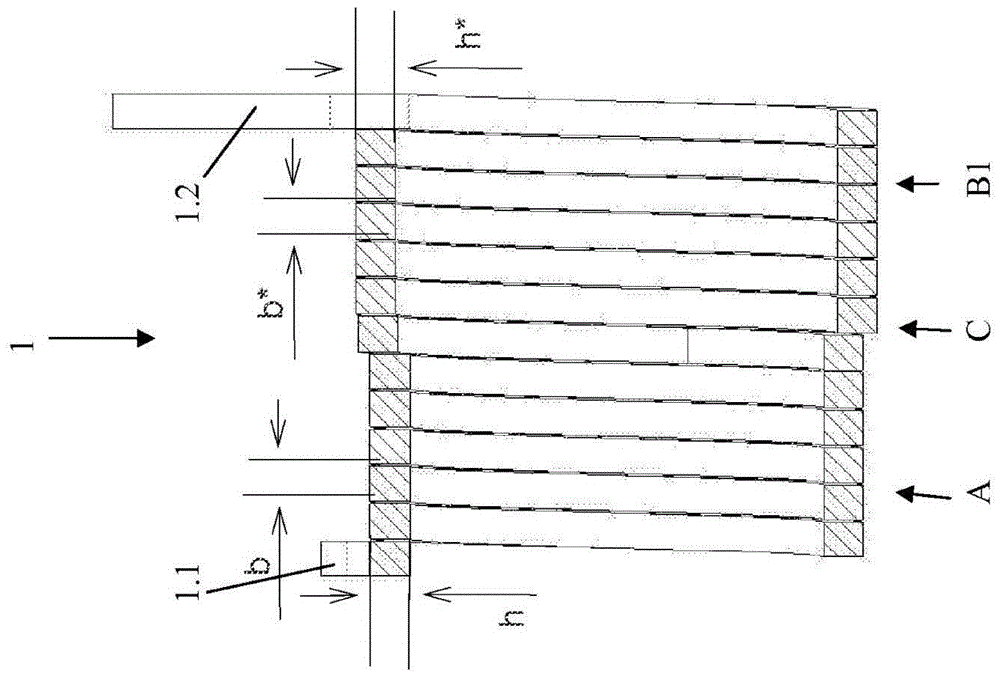

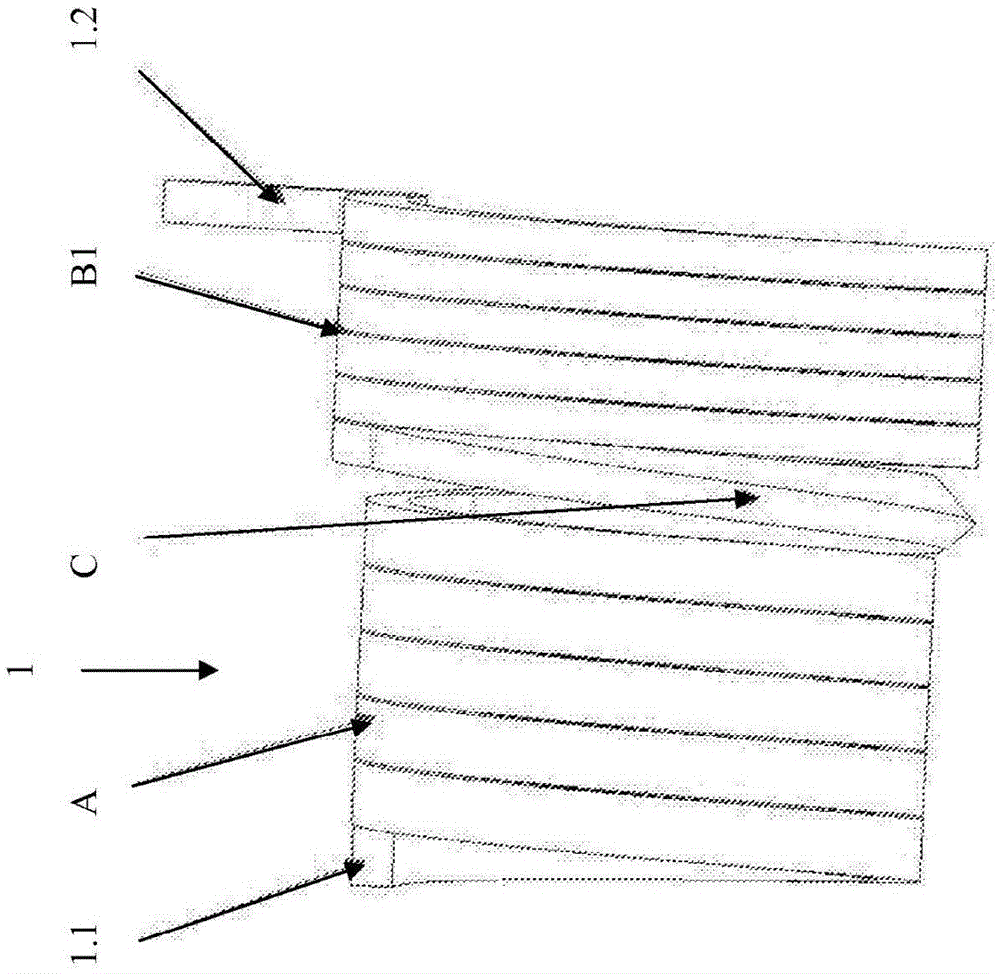

[0067] according to figure 1 and 2 , the first area A serving as a wrap spring (Eitelwan formula) has a first end 1.1 which is bent radially outwards, wherein a constant friction is established on the end 1.1 or via the first A constant or variable pre-interference of area A to the hub (outer diameter) to create friction. Furthermore, there is a second region B1 serving as a torsion spring with a second end 1 . 2 , which is likewise bent radially outward. Transition region C connects regions A and B to each other. The inner and outer diameters of the helix are larger in regions B1 and C than in region A.

[0068] The same width b and height H of the cross-section of the helix are present in all regions.

[0069] according to image 3 (three-dimensional view) and 4 (longitudinal section), the torsion spring 1 likewise has regions A, B1, C, wherein region C is however twisted by 90°. The rectangular cross-section of the helix thus has a height h and a width b in the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com