Metal dust pollution on-line monitoring device for insulator, and monitoring method thereof

A metal dust and monitoring device technology, applied in measuring devices, suspension and porous material analysis, instruments, etc., can solve the problem that the leakage current method is susceptible to electromagnetic interference, cannot accurately monitor the pollution degree of insulators in steel plants, and is prone to false alarms Issues such as underreporting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below with reference to the drawings and specific embodiments.

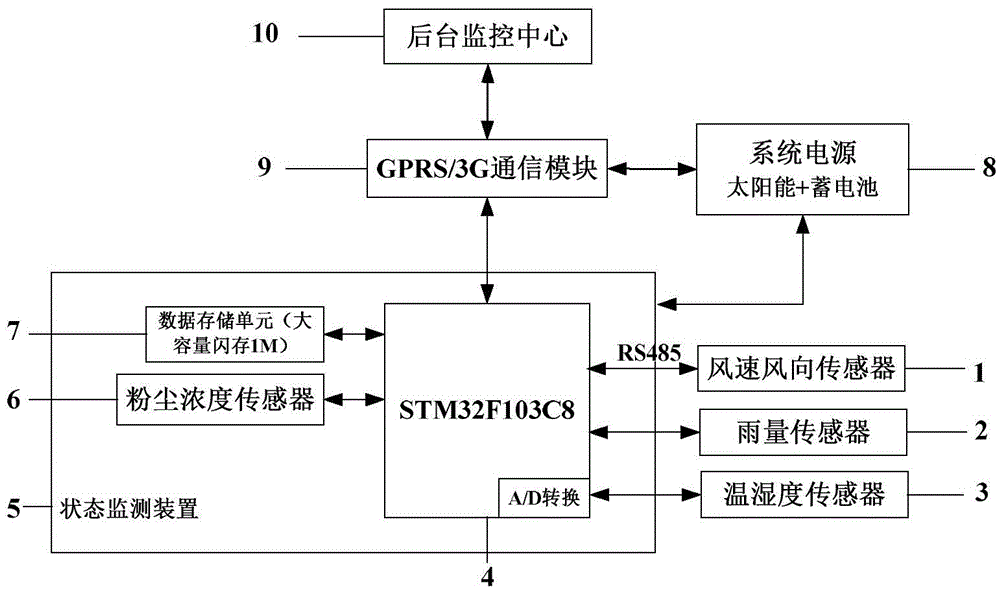

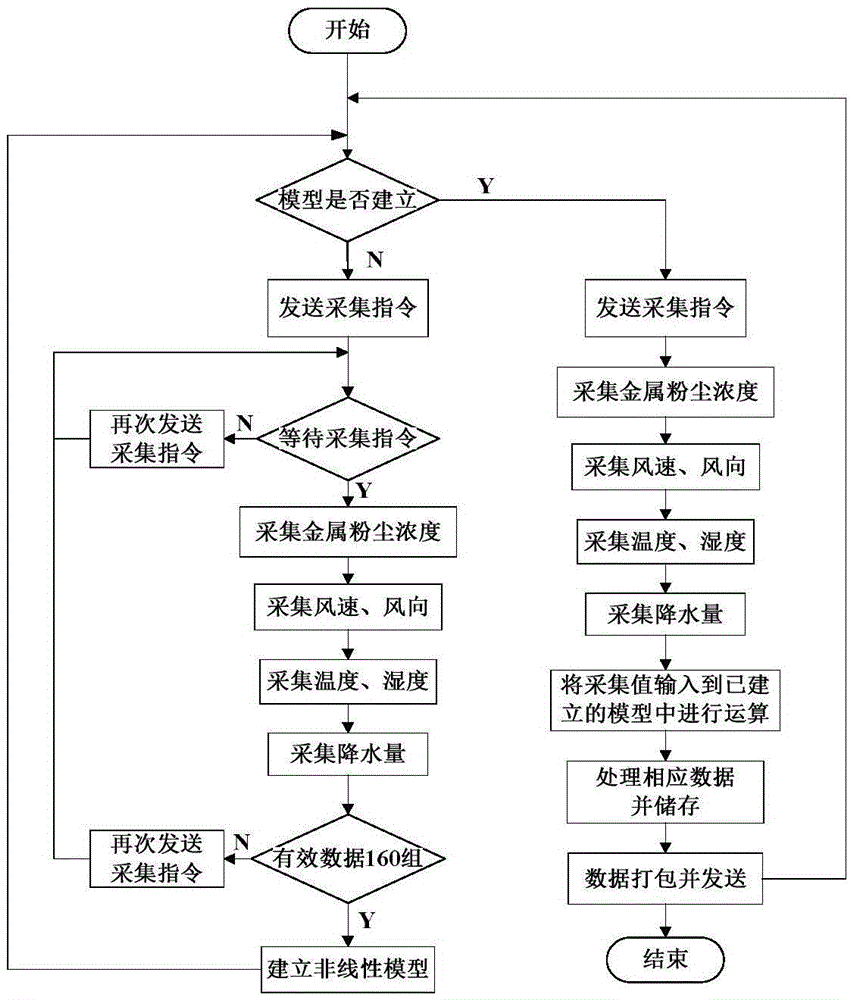

[0046] The invention provides an online monitoring device for metal dust contamination of insulators, such as figure 1 As shown, the condition monitoring device 5 and the wind speed and direction sensor 1, the rainfall sensor 2 and the temperature and humidity sensor 3 connected to it, the condition monitoring device 5 includes a microcontroller 4 and a data storage unit 7 and a dust concentration sensor 8 connected to it. , The condition monitoring device is also connected with the system power supply 8 and the GPRS / 3G communication module 9, and the GPRS / 3G communication module 9 is connected with the background monitoring center 10 and the system power supply 8.

[0047] The wind speed and direction sensor 1, the rainfall sensor 2 and the temperature and humidity sensor 3 are all connected to the microcontroller 4,

[0048] Wind speed and direction sensor 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com