Automotive blower flange testing fixture

A blower and inspection tool technology, applied in the field of auto parts processing, can solve problems such as affecting the quality of the flange, easy damage, and easy deformation of the flange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

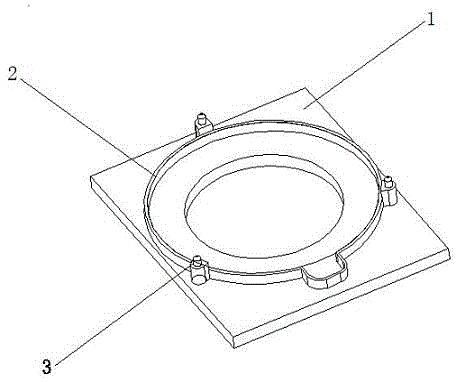

[0008] like figure 1 As shown, a kind of automobile blower flange inspection tool, it comprises panel 1, detection rib 2, detection pin 3, described panel 1 is provided with detection rib 2, and detection rib 2 is provided with several detection pins 3 .

[0009] The invention is composed of a panel, on which a detection rib is arranged, and several detection pins are arranged on the detection rib, when the flange plate needs to be detected, the flange plate is first put into the detection rib, If the size is qualified, it can be put in, otherwise it can’t, and then fix the flange with the detection pin, then place it for a period of time, open the detection pin, take off the flange, the flange is detected by the ribs and the detection pin After shaping, it meets the needs of the automobile blower, which not only can shape the flange, but also improves the detection efficiency of workers.

[0010] The invention can shape the flange and detect it, which not only improves the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com