Bearing outer ring

A bearing outer ring and outer ring technology, which is applied in the field of bearing outer rings, can solve the problems that the outer ring's stress point is not very firm, shorten the service life of the bearing, affect the stability of the bearing, etc., achieve excellent wear reduction and improve sealing , The effect of firm positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

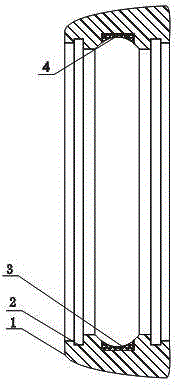

[0012] Such as figure 1 As shown, a bearing outer ring includes an outer ring body 1. The outer peripheral surface of the outer ring body 1 is conical. The diameter of one end surface of the outer ring body 1 is larger than the diameter of the other end surface. A raceway 3 for cylindrical rollers to roll and two seal grooves 2 for installing seal rings are provided. The two seal grooves 2 are respectively located on both sides of the raceway 3, and the raceway 3 is provided with a lubricating liner 4 ; Threads are provided on the tapered surface of the outer ring body 1 .

[0013] During the long-term use of the bearing, the liner in the raceway will be gradually worn out. In order to facilitate maintenance and replacement, the raceway 3 and the outer ring body 1 can be detachably connected.

[0014] In the present invention, the outer surface of the outer ring body is set as a conical surface and threads are provided on the conical surface. When installing with the bearing ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap