Centrifugal fan and air conditioner

A centrifugal fan and air conditioner technology, applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve problems such as airflow blockage at the inlet of the ventilation duct, affecting the working efficiency of the fan, and large dynamic noise of the wind wheel, so as to increase kinetic energy, Effect of reducing air separation phenomenon and suppressing growth of boundary layer thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

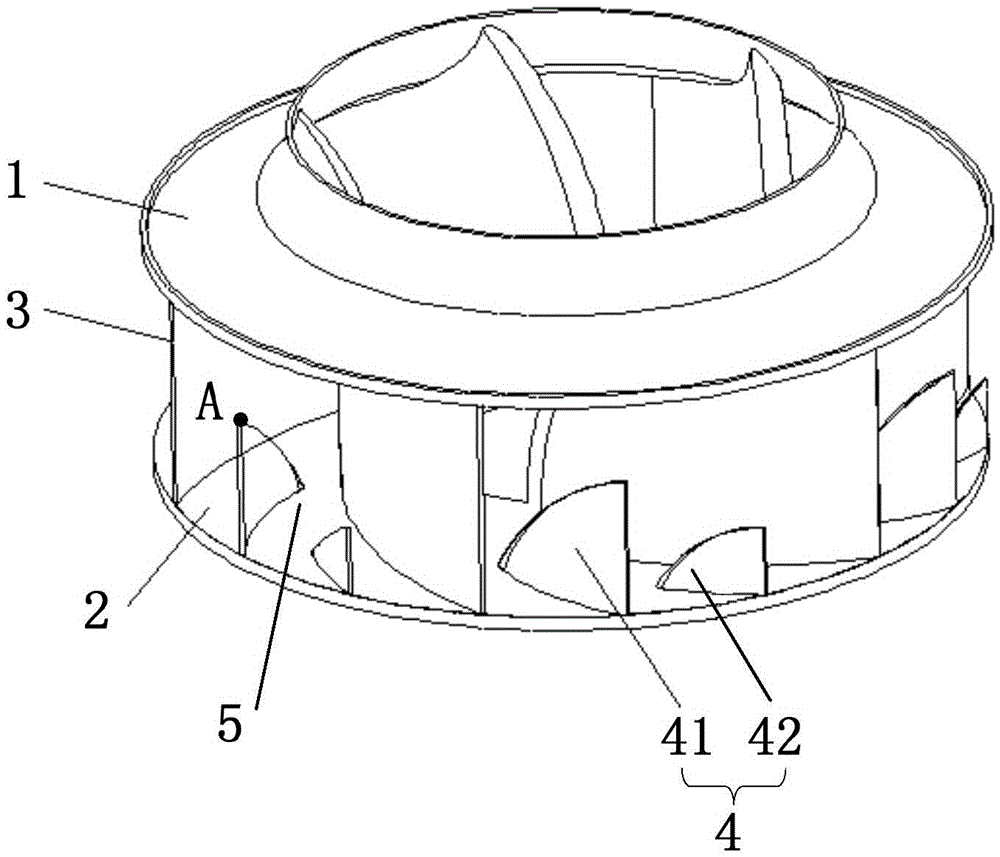

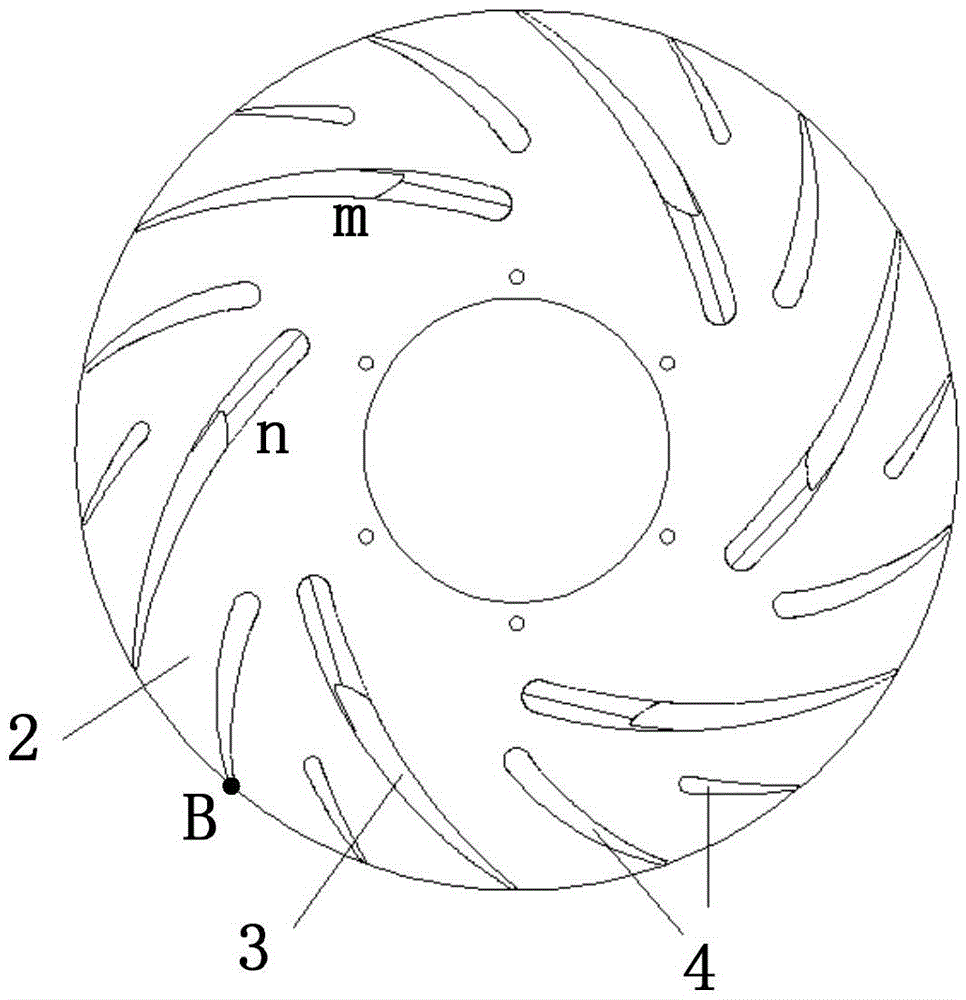

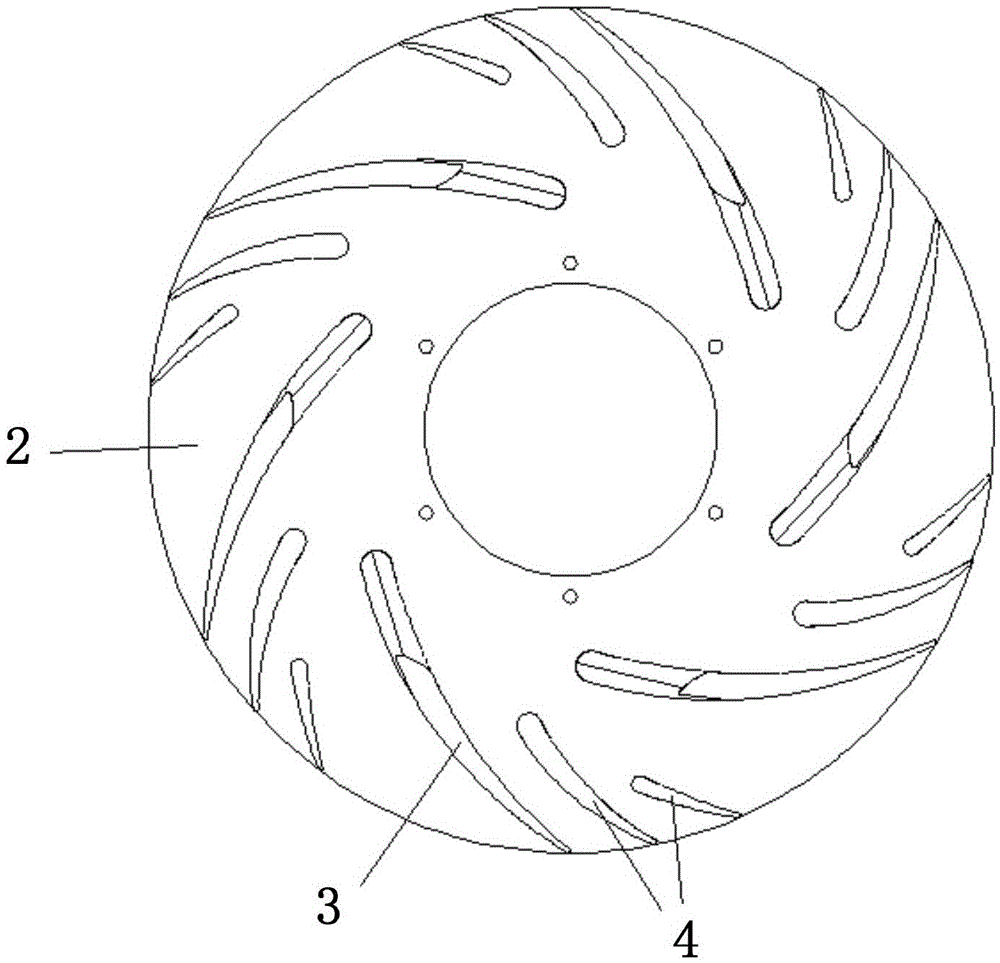

[0025] Combine below Figure 1 ~ Figure 4 The technical solution provided by the present invention is described in more detail.

[0026] see figure 1 and figure 2 , Embodiment 1 of the present invention provides a centrifugal fan, which may specifically be a backward centrifugal fan. It includes a first disc 1, a second disc 2, and blades 3 arranged between the first disc 1 and the second disc 2, and a guide channel 5 is formed between two adjacent vanes 3; wherein, the guide channel 5 A deflector 4 is provided inside, and the deflector 4 is used to reduce the cross-sectional area of the flow guide channel 5 so as to increase the air velocity in the guide channel 5 . The vanes 4 and the vanes 3 have the same shape but different sizes.

[0027] In this embodiment, the first disc 1 is the front disc, and the second disc 2 is the rear disc.

[0028] In the above technical solution, a guide vane 4 is added to the guide channel between the blades 3 of the centrifugal fan, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com