Drainage pipe system

A technology for drainage pipes and pipe bodies, which is applied to drainage, safety devices, mining equipment, etc., can solve problems such as inability to drain in time, long operation time, etc., and achieve the effects of improving centralized drainage, high pressure resistance, and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

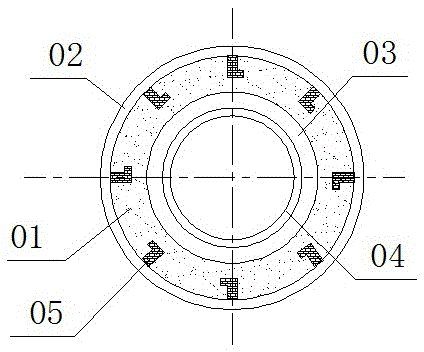

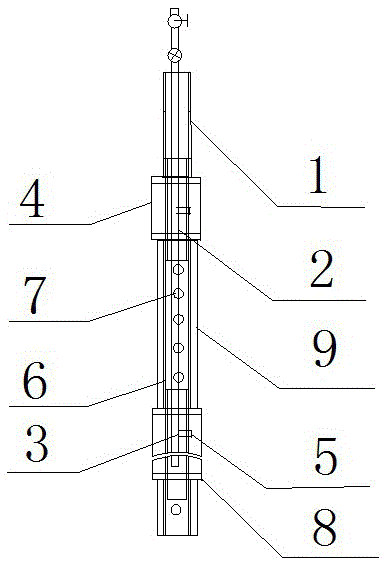

[0027] Such as figure 2 As shown, the drainage pipe system includes an expansion part and a seepage part, wherein the expansion part includes at least one section of pipe body I1 made of seamless steel pipe, and the outside of the pipe body I1 is wrapped with an annular hollow inflatable air bag 4. The main ventilation pipe 2 made of seam steel pipe is placed in the pipe body I1, and the main ventilation pipe 2 is provided with ventilation holes 3 equal in number to the annular hollow inflatable airbag 4, and the annular hollow inflatable airbag 4 The ventilation pipe 5 communicates with the ventilation hole 3 of the main ventilation pipe 2 through the pipe body I1, and the water seepage part includes at least one pipe body II6 made of seamless steel pipe, and the pipe body I1 is separated from the pipe body II6 It is set and communicated, and at least one drain hole 7 is set on the pipe body II6, and one end of the drain pipe is inserted into the surrounding rock for sealing...

Embodiment 2

[0030] Such as figure 2 As shown, on the basis of Example 1, blocking gaskets 8 are provided on both sides of the annular hollow inflatable airbag 2, and the blocking gasket 8 effectively limits the longitudinal deformation of the annular hollow inflatable airbag 2, and enhances the airbag's impact on the surrounding area. The radial extrusion of the rock is more conducive to the rapid fixation of the drainpipe.

Embodiment 3

[0032] Such as figure 2 As shown, on the basis of Example 1, the pipe body II6 is wrapped with non-woven fabric 9, and the non-woven fabric 9 provides a good drainage channel for the seepage of surrounding rock, so that the drainage pipe can drain water more effectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com