Oxygen generation control system of PSA oxygen generator

A technology of control system and oxygen generator, applied in the direction of oxygen/ozone/oxide/hydroxide, inorganic chemistry, oxygen preparation, etc., can solve the problems of poor controllability, drainage failure, inconvenient setting of drainage time, etc., and achieve reduction The effect of air compressor failure and prevention of ice blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

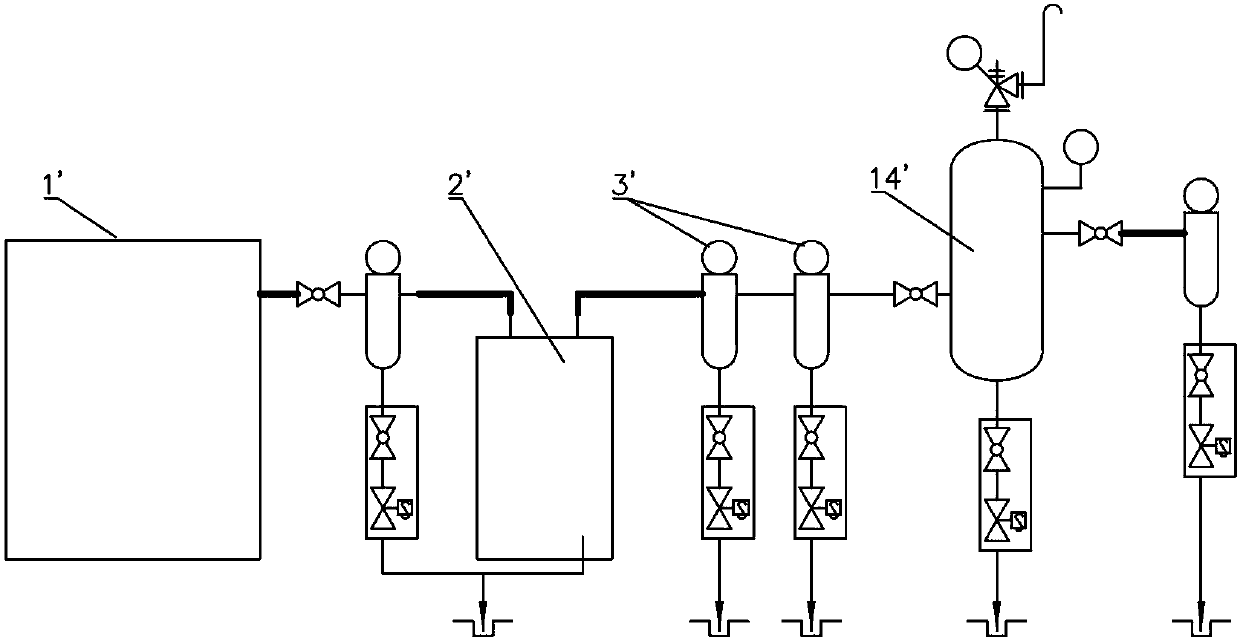

[0028] The present invention is an oxygen production control system for a PSA oxygen generator. The PSA oxygen generator includes an air compressor 1, a cold dryer 2, and an oxygen generator 3. The oxygen generator includes a box body and is installed in the box body. The pipeline assembly, the adsorption tower assembly and the control system on the top of the box are equipped with a pressure gauge, a display assembly and an alarm system. The adsorption tower assembly includes a first adsorption tower assembly and a second adsorption tower assembly. An adsorption tower component includes a first upper vent and a first lower vent, and the second adsorption tower component includes a second upper vent and a second lower vent;

[0029] The oxygen production control system of the PSA oxygen generator includes at least an air tank drainage system 10, an oxygen concentration adjustment control and alarm system 11, a cold dryer control system 12, a PLC control program 13, and a networ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com