Mobile mining face dust remover

A technology of mining face and dust collector, applied in the fields of dust prevention, mining equipment, earth-moving drilling, etc., can solve problems such as life-threatening, silicosis in workers, and dust accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

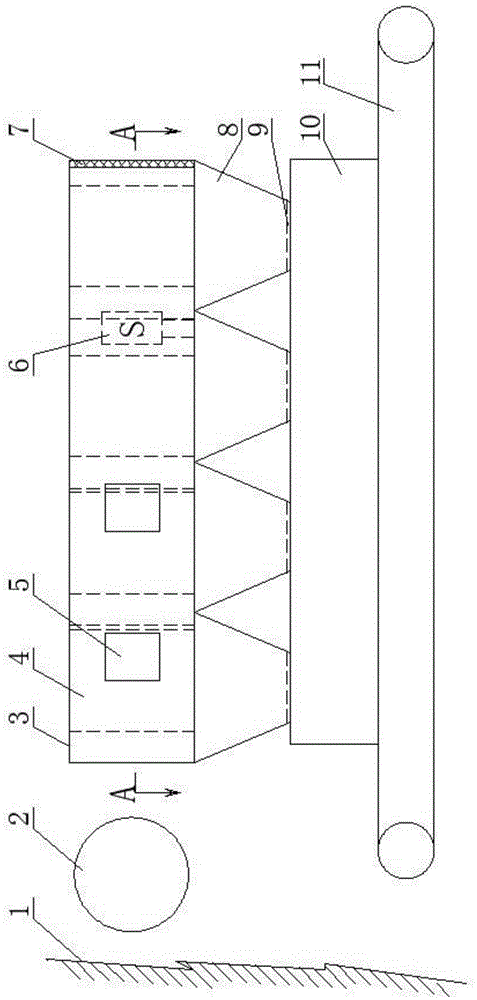

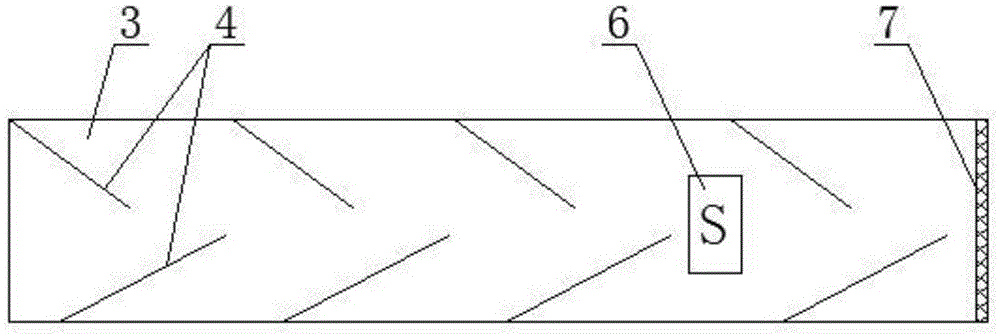

[0014] like figure 1 As shown, the mobile mine mining surface dust collector includes a dust cover body 10, a plurality of flap type ash unloading hoppers 8 arranged above the dust cover body 10, and is located between the flap type ash unloading hopper 8 and the dust cover body. 10 between the flap type ash unloading valve 9, the dust guide channel 3 arranged above the flap type ash unloading hopper 8 and communicated with each flap type ash unloading hopper 8, the axial flow fan 6 and the lowering fan located in the dust guide channel 3 Energy blocker4. One end of the dust guiding channel 3 close to the mining face 1 is open to communicate with the mining face space, and the other end is provided with a filter screen 7, and a plurality of dust suction ports 5 are evenly arranged on the side wall and the top of the channel along the length direction of the channel. The axial flow fan 6 is fixed near the end of the filter screen 7 . The energy-reducing blockers 4 are plate-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com