Automated drilling rig

A technology for drilling rigs and mechanical arms, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc. It can solve the problems of high risk, high labor intensity of workers, and low degree of automation, so as to achieve good force bearing, reduce labor intensity, and improve The effect of moving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

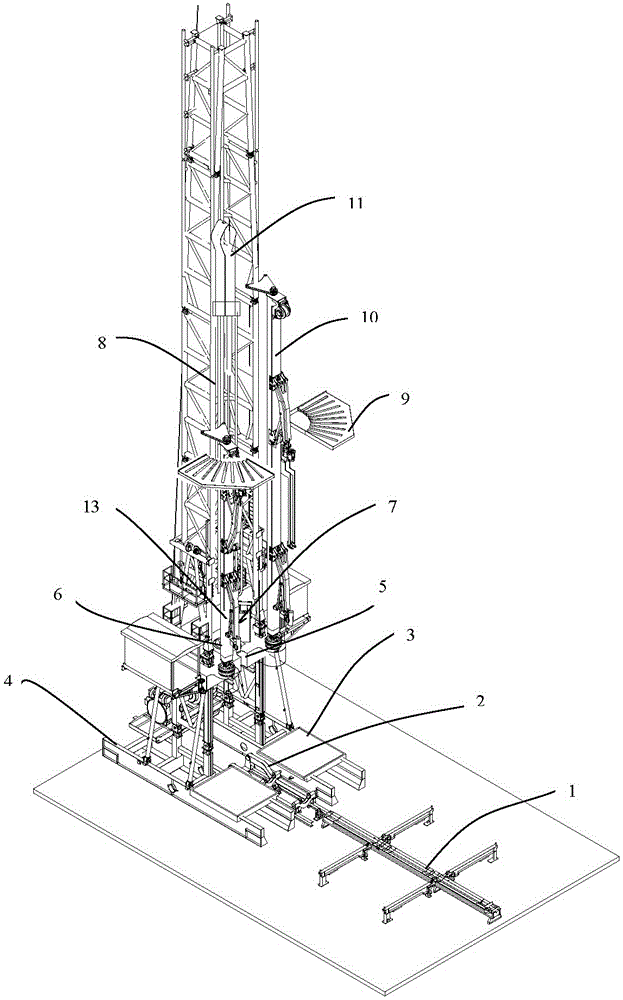

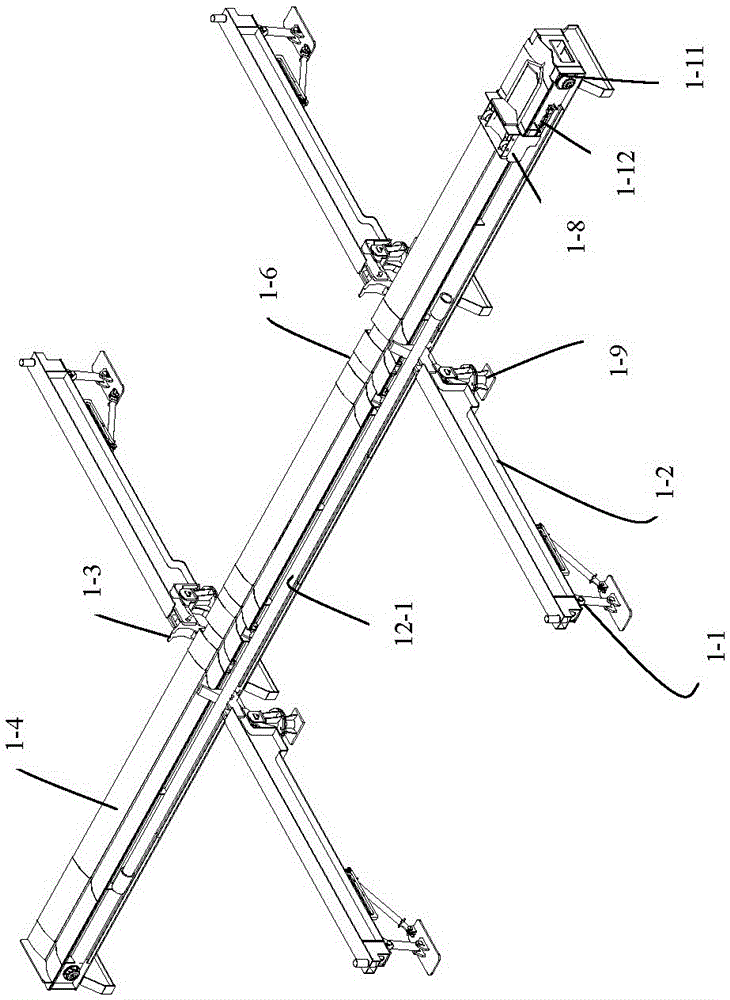

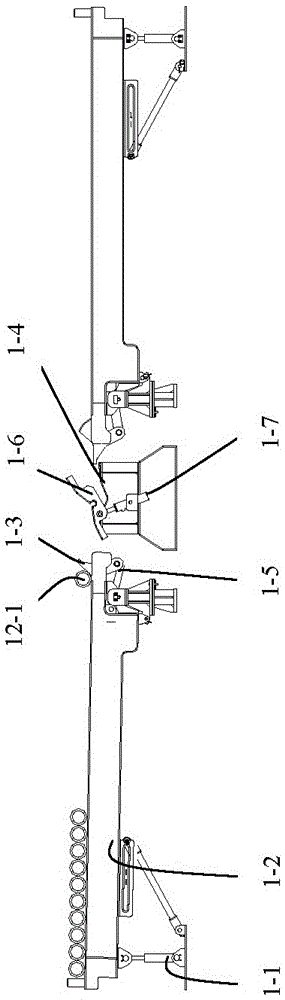

[0052] Such as figure 1 As shown, the main equipment of the drilling rig in this embodiment includes from low to high and from left to right: catwalk 1, turning manipulator 2, base 4, root box 3, power slips 6, iron driller 7, jack-up Derrick 8, double fan-shaped finger beam 9, long pipe arrangement machine 10, top drive 11, short pipe arrangement machine 13. Among them, the overturning manipulator 2 is installed on the ground of the well site, the stand box 3 is installed on the base 4, the double fan-shaped finger beams 9 are located on both sides of the jack-up derrick 8, and the double-row pipe machine 10 is installed on the rear gate side of the jack-up derrick 8

[0053] The catwalk 1 is installed on the surface of the well site, which ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com