Screen glass film pasting moving device and method and film pasting equipment

A glass film and screen technology, applied in lighting and heating equipment, packaging, transportation and packaging, etc., can solve the problems of reducing the applicability of the moving device, reducing the moving efficiency, increasing the moving distance, etc., to achieve low cost, reduce cost, The effect of reducing the amount used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

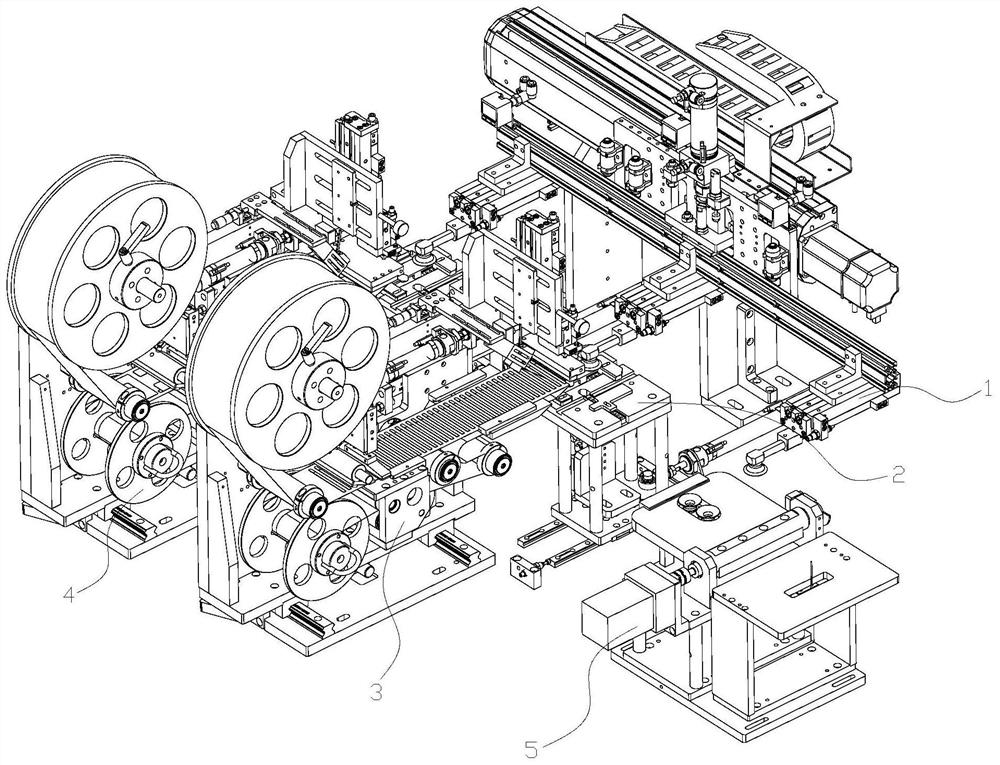

[0030] Such as figure 1 Shown is a screen glass protective film pasting device, which includes a workbench and a feeding device fixed on the workbench, a moving device 1, a plurality of positioning devices 2, a first film supply device 3, and a second film supply device 4 and turning device 5; the moving end of the moving device 1 is in contact with the screen glass surface and is respectively connected with the positioning ends of a plurality of positioning devices 2 and the feeding and discharging ends of the turning device 5; the discharging end of the first film feeding device 3 and the second feeding device The discharge end of the film device 4 is respectively connected with the positioning ends of multiple positioning devices 2; the moving device 1 is used to move the screen glass to different stations; the positioning device 2 is used to position the screen glass; the first film supply device 3 and the second The two film feeding devices 4 are used for feeding the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com