An interception, decompression and anti-floating system

A technology for decompression well pipes and underground structures, applied in protection devices, buildings, infrastructure engineering and other directions, can solve problems such as hidden dangers left in the subsequent development of underground spaces, excessive pressure on drainage structures, and increased risk of silting. Optimize the effect of anti-floating, reduce water pressure and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings. Obviously, the embodiments described below are only part of the embodiments of the present invention.

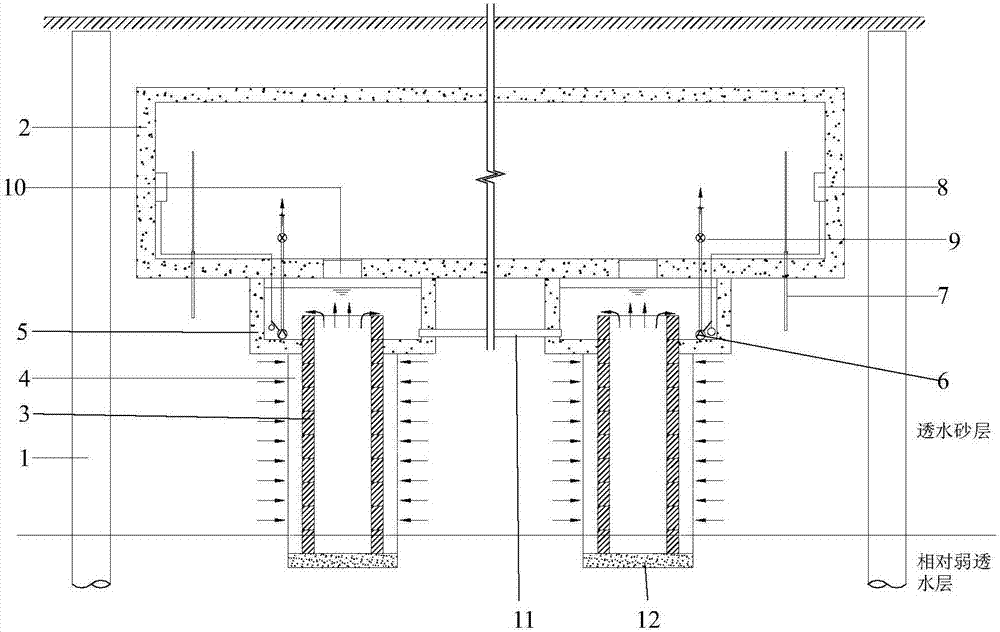

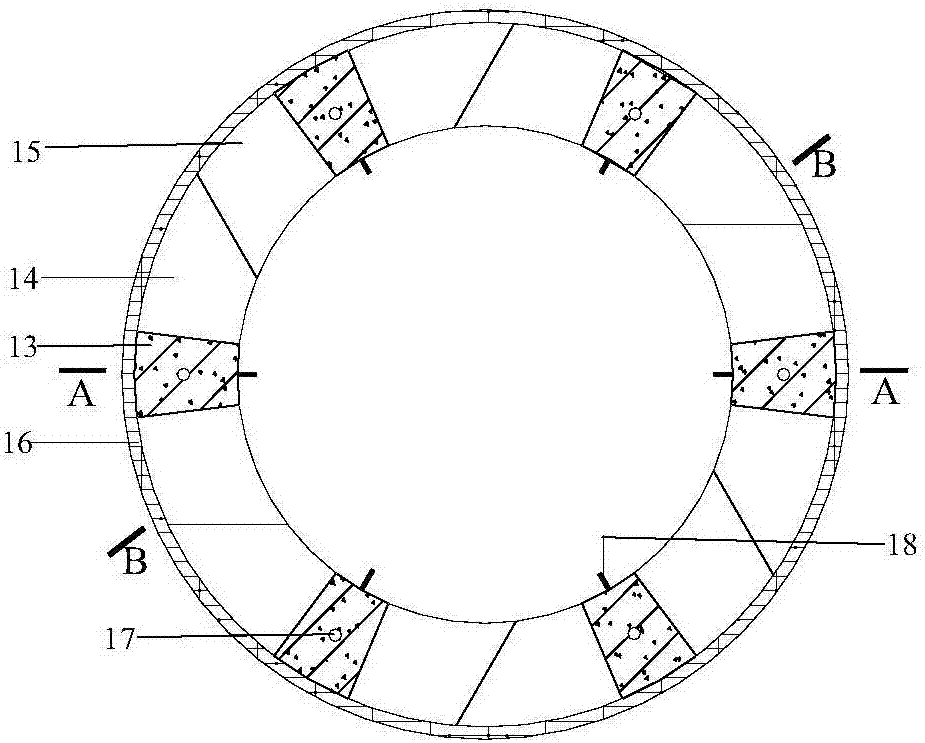

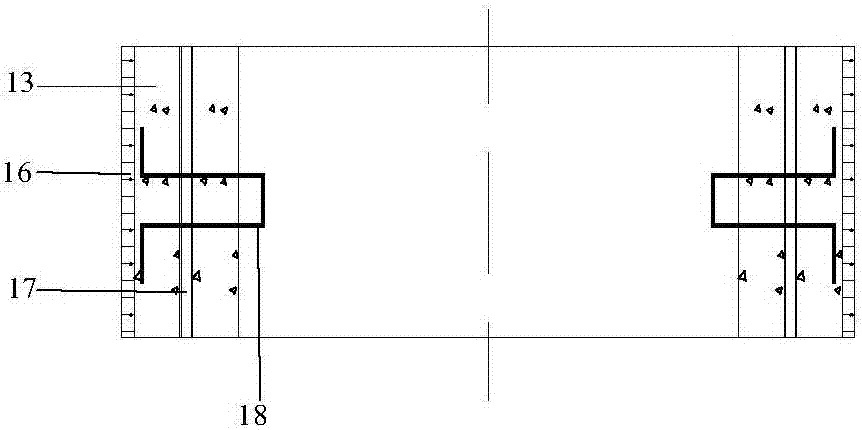

[0027] Such as figure 1 As shown, the present invention provides a kind of cut-off decompression anti-floating system, including water-stop curtain 1 arranged around the underground structure 2, several sumps 5 are arranged under the bottom plate of the underground structure 2, and the water-collecting The pit 5 is provided with a submersible pump 6 connected to the circuit of the submersible pump automatic control cabinet and a water level sensor switch. The bottom of the sump 5 is provided with a well hole extending downward, and a decompression well pipe is provided in the well hole. A reverse filter layer 4 with a thickness of not less than 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com