Electrospinning device with mechanical stirring and liquid supply

A technology of electrospinning and mechanical agitation, which is applied in textiles and papermaking, filament/thread forming, fiber processing, etc. It can solve the problems of high stability requirements of centrifugal spinning machinery, difficulties in directional collection of collectors, and low output of fiber manufacturing and other problems, to achieve the effect of reducing long-term high-speed rotation state, realizing large-scale industrial production, improving efficiency and fiber quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

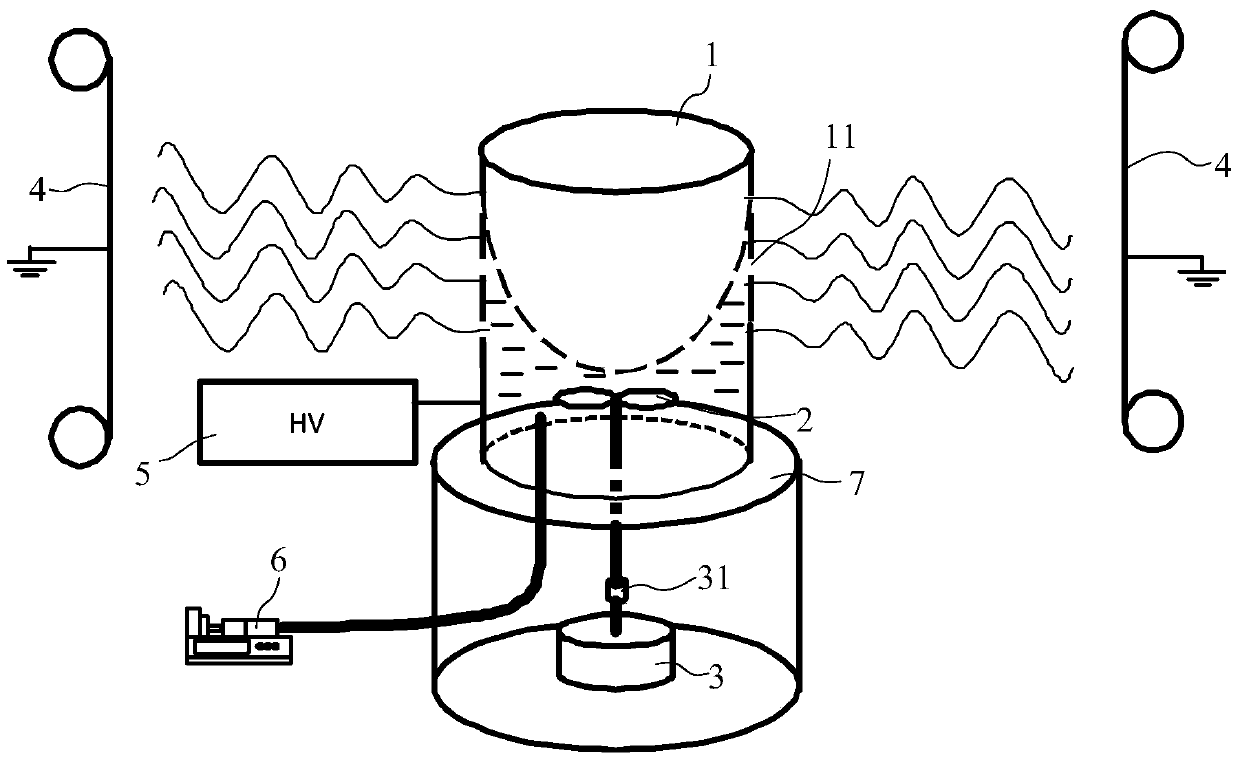

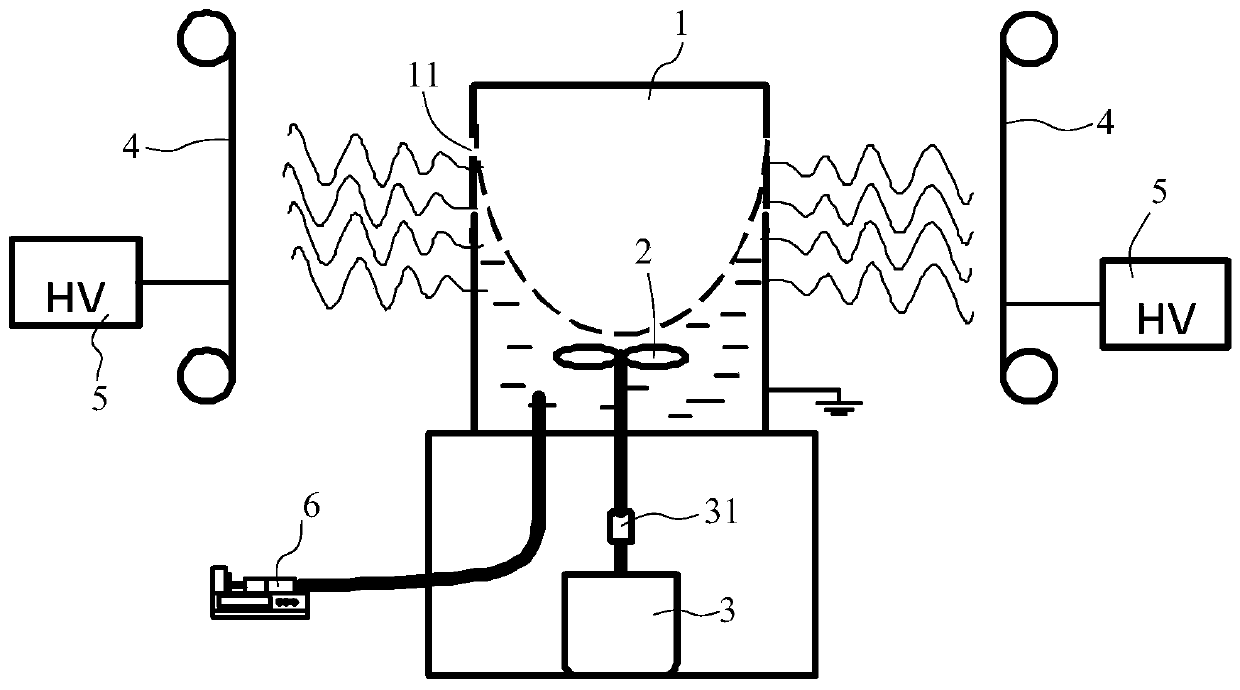

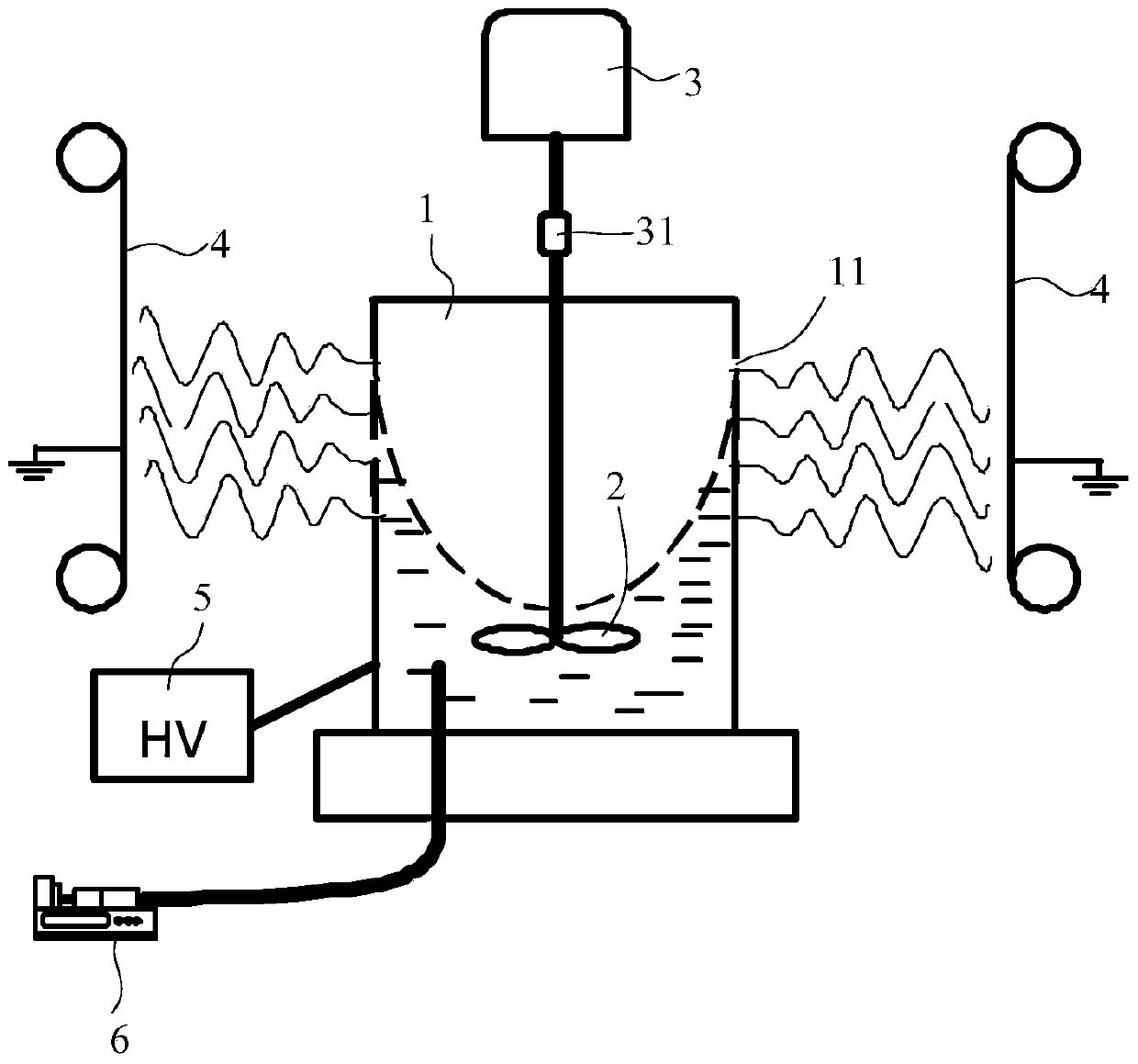

[0027] refer to Figure 1 to Figure 4 , which shows the specific structure of the preferred embodiment of the present invention. The structural features of each element of the present invention will be described in detail below, and if there is a description of the direction (up, down, left, right, front and back), it is based on figure 2 The shown structure is a reference description, but the actual use direction of the present invention is not limited thereto.

[0028] see Figure 1 to Figure 3 , the present invention provides a mechanical stirring liquid supply electrospinning device, comprising a container 1, a stirring impeller 2, a driving system 3, a collecting device 4, a power supply 5 and continuously supplying spinning solution or melt into the container 1. The liquid supply device 6 of the body, the container 1 is made of transparent, corrosion-resistant and non-reactive materials with organic solvents. The liquid supply device 6 is connected to the container 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com