Iron-containing organic metallurgical pellet binder and preparation method thereof

A binder and organic technology, applied in the field of iron-containing organic metallurgical pellet binders, to achieve the effects of high-efficiency adhesion, large burning loss, and low ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

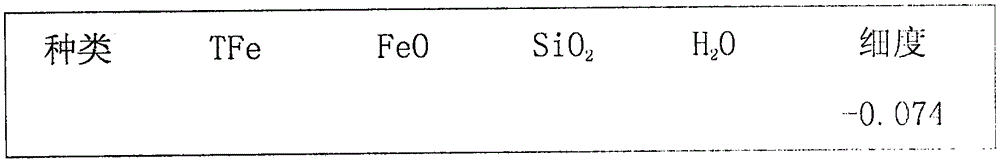

[0019] An iron-containing organic metallurgical pellet binder, the composition weight percent of which is: 1%-3% of polyacrylamide, 30%-40% of sodium humate, 6%-10% of borax, and 8% of sodium nitrate ~15%, iron ore powder 30~60%.

Embodiment 2

[0021] The iron-containing organic metallurgical pellet binder comprises the following components by weight percentage: 2% of polyacrylamide, 35% of sodium humate, 8% of borax, 10% of sodium nitrate, and 45% of iron ore powder.

[0022] The particle size of the polyacrylamide is 70 meshes, the molecular weight of the polyacrylamide is >15 million, and the moisture content of the polyacrylamide is ≤5%.

[0023] The sodium humate is composed of water-soluble humic acid and water-insoluble matter, wherein the content of the water-soluble humic acid is ≥70%, the water-insoluble matter is ≤12%, and the water content of the sodium humate is ≤ 15%.

[0024] The particle size of the borax is 70 meshes, and the moisture content of the borax is ≤15%.

[0025] The particle size of the sodium nitrate is 60 mesh, and the water content of the sodium nitrate is ≤10%.

[0026] The iron ore powder is one or more of iron-containing material powders such as hematite powder, pellet return ore p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com