Production method of fish collagen peptide chelated calcium

A technology of fish collagen peptide and production method, applied in the production of fish collagen peptide chelated calcium from fish scales, using fish bones and fish skin, can solve problems such as environmental pollution and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

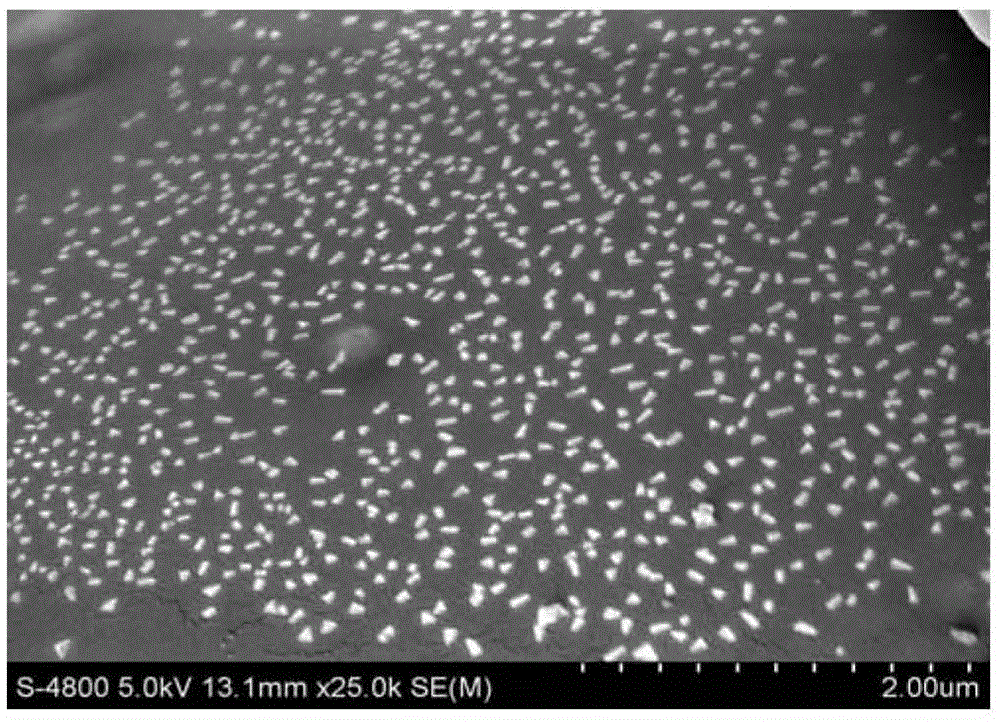

Image

Examples

Embodiment 1

[0022] Add 5 L of 0.4% Ca(OH) containing 0.75% sodium percarbonate to 1 kg of tilapia fish bones 2 Solution, soaked at 4°C for 48h, rinsed with tap water, drained properly, added 1L of pure water (the final volume of the sample was about 2.0L), heated to 100°C for 60min, cooled to 50°C, and washed with 1% Ca(OH) 2 After adjusting the pH of the fish scale aqueous solution to 9.5, add 5g of alkaline protease, enzymolyze at 40°C for 4 hours, heat at 100°C for 5min to inactivate the enzyme, cool to 50°C, and adjust the pH of the enzymolysis solution with 1% food-grade phosphoric acid to 4.0, add 10g calcium chloride, stir, every 30min during the stirring process, use 0.1%Ca(OH) 2 Solution Increase the pH of the proteolysis solution to 4.5, 5.0, 5.5, and 6.0 in sequence, and make the calcium chelate at these pHs for 30 minutes, and finally adjust the pH of the solution to 8.5, add 18g of activated carbon and stir for 30 minutes. Centrifuge removes gac, then utilizes the ceramic m...

Embodiment 2

[0024] Add 2L of 0.1% Ca(OH) containing 0.5% sodium hypochlorite to 1kg large yellow croaker scales 2 Soak the solution at 4°C for 24 hours, rinse it with tap water, drain properly, add 1L of pure water (the final volume of the sample is about 1.8L), heat up to 100°C for 45min, cool to 45°C, and use 1% Ca(OH) 2 After adjusting the pH of the fish scale aqueous solution to 9.0, add 0.3g of collagenase, enzymolyze at 45°C for 5 hours, heat at 90°C for 15min to inactivate the enzyme, cool to 45°C, and adjust the pH of the enzymolysis solution to 1% food grade phosphoric acid. 4.0, add 13.5g calcium chloride, stir, every 30min during stirring, use 0.1%Ca(OH) 2 Solution Increase the pH of the proteolysis solution to 4.5, 5.0, 5.5, and 6.0 in sequence, and make the calcium chelate at these pHs for 30 minutes, and finally adjust the pH of the solution to 8.0, add 20g of activated carbon and stir for 30 minutes, and use a disc Centrifuge removes gac, then utilizes the ceramic membran...

Embodiment 3

[0026] Add 4L of 0.3% Ca(OH) containing 1.0% potassium hypochlorite to 1kg silver carp skin 2 Soak the solution at 4°C for 36 hours, rinse it with tap water, drain it properly, add 1L of pure water (the final volume of the sample is about 2.5L), heat up to 100°C for 45min, cool to 40°C, and use 1% Ca(OH) 2 After adjusting the pH of the fish scale aqueous solution to 8.5, add 0.1g trypsin, enzymolyze at 40°C for 6h, heat at 80°C for 30min to inactivate the enzyme, cool to 40°C, and adjust the pH of the enzymolysis solution to 4.0, add 25g calcium chloride, stir, every 30min during the stirring process, use 0.1%Ca(OH) 2Solution Increase the pH of the proteolysis solution to 4.5, 5.0, 5.5, and 6.0 in turn, and make the calcium chelate at these pHs for 30 minutes, and finally adjust the pH of the solution to 7.5, add 25g of activated carbon and stir for 30 minutes. Centrifuge removes gac, then utilizes the ceramic membrane filtration that pore size is 50nm, desalination by nanof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com